Improved glass fiber reinforced PC/ASA composition

A technology of composition and glass fiber, which is applied in the field of glass fiber reinforced PC composition materials, can solve the problems of high cost, high cost of raw materials, and increased cost, and achieve improved anti-aging and weather resistance, high-temperature discoloration resistance, and anti-aging The effect of pyrolysis enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

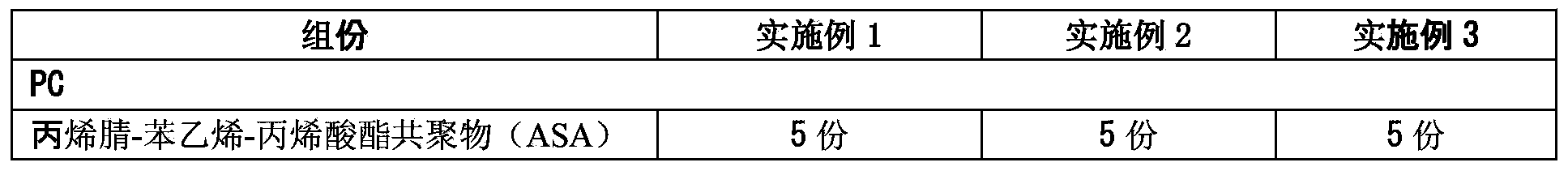

[0038] Examples: Table 1 shows the components of Example 1, Example 2 and Example 3 of the present invention, and each component in Table 1 is calculated in parts by weight.

[0039] Table 1

[0040]

[0041]

[0042] The above embodiments are all made according to the conventional extrusion granulation process of the prior art, that is, after mixing the components uniformly, extrusion granulation is carried out to obtain the improved glass fiber reinforced PC / ASA composition of the present invention. Use a high-speed mixer to stir, use a 75# twin-screw extruder for extrusion, and the speed is 400r / min. The temperature is 255°C, and the temperature in zone five is 250°C.

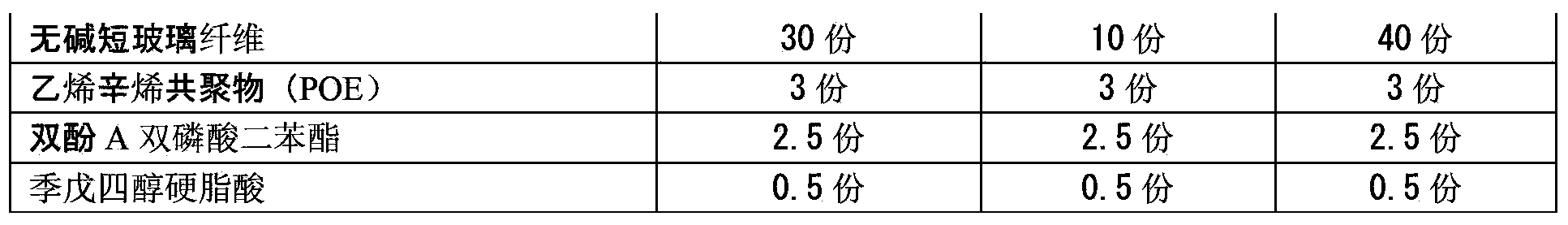

[0043] Table 2 has provided the performance test condition of each embodiment

[0044] Table 2

[0045]

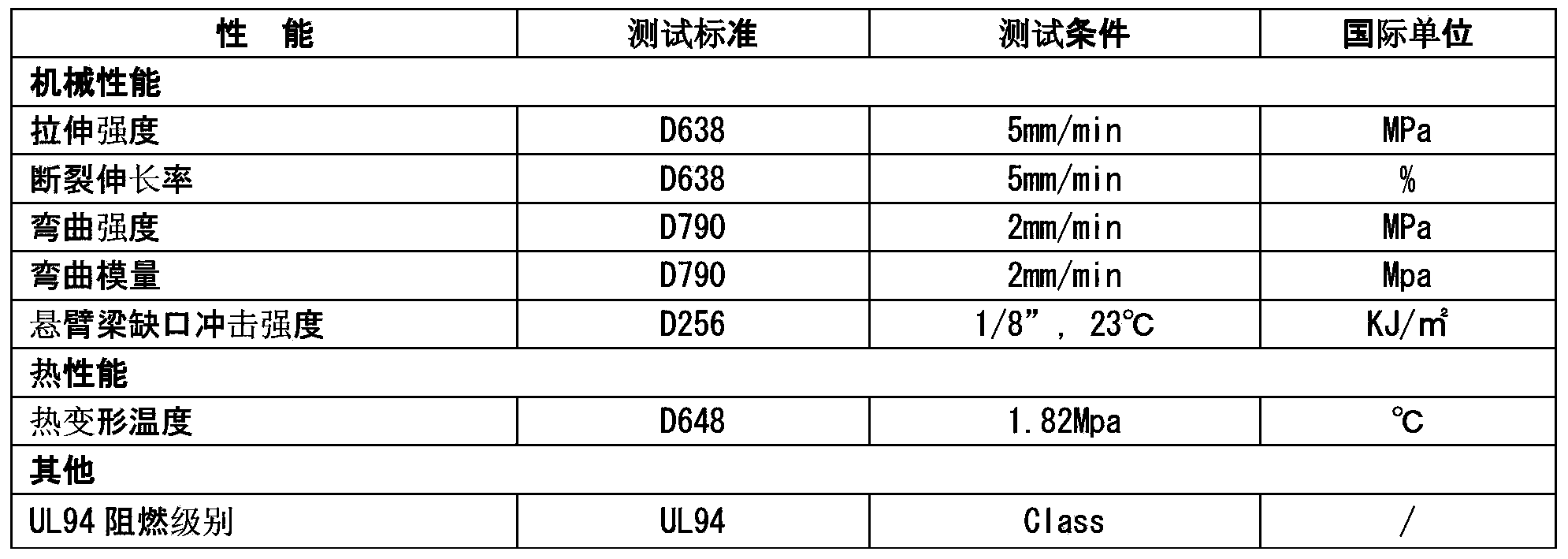

[0046] Table 3 has provided the performance index of each embodiment

[0047]

[0048] Obviously, this improved glass fiber reinforced PC / ASA composition of the present invention has high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com