Mechanism natural sand gradation adjustment machine special stepping impact hopper and sand making method

A grading adjustment machine and natural sand technology, applied in grain processing, etc., can solve problems such as low production capacity, waste of raw materials, and decline in overall product quality, and achieve the effects of high production capacity, avoiding waste of raw materials, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

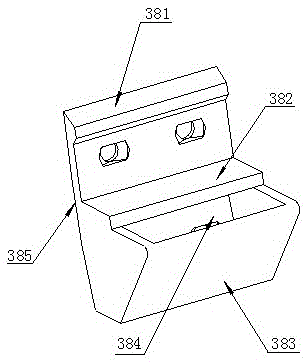

[0014] Embodiment 1: with reference to attached figure 1 . A special stepping counterattack hopper for mechanism natural sand gradation adjustment machine. The stepping counterattack hopper 38 is a fixed-wall trapezoidal bucket. The first counterattack panel 382 is welded on the part of the cavity of 384, the front bucket surface of the fixed wall type trapezoidal bucket is the second counterattack panel 383, and the back side of the fixed wall type trapezoidal bucket is an assembly panel 385. The stepping impact hopper itself is made of high manganese steel. The section of the counter-attack rack 381 is trapezoidal.

Embodiment 2

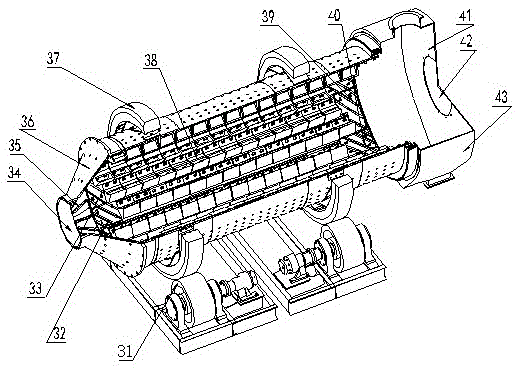

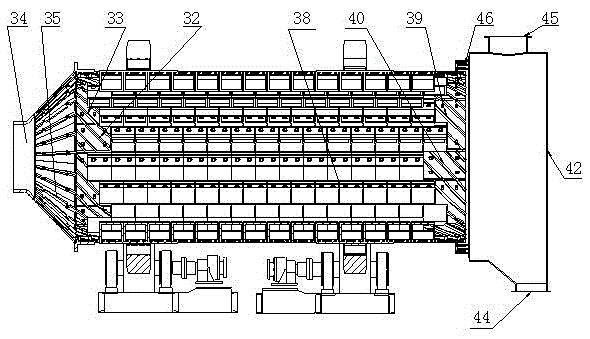

[0015] Embodiment 2: with reference to attached Figure 2-6 . A mechanism natural sand gradation adjustment machine composed of a step-by-step counterattack hopper. The mechanism natural sand gradation adjustment machine 3 consists of a power source 31, a second material guide lining 32, a first material guide lining 33, and a feed port Wear-resistant ring 34, feed port lining plate 35, feed port shell 36, large rolling ring 37, stepping counterattack hopper 38, third material guide lining plate 39, fourth material guide lining plate 40 and dust cover 43; the two ends of the drum are respectively covered with large rolling rings 37, the large rolling rings 37 are located on the power source 31, the sand dust cover 43 is set on one end of the drum, the wear-resistant ring 34 of the feed port, the lining plate 35 of the feed port and The feed inlet shell 36 constitutes the feed inlet, and a plurality of step-type impact hoppers 38 are arranged in three or more rows as a group a...

Embodiment 3

[0017] Example 3: On the basis of Examples 1 and 2, a sand making method of a machine-made natural sand grading adjustment machine composed of a step-by-step counterattack hopper, steel balls and machine-made natural sand that need to be adjusted enter the machine-made natural sand grade together Equipped with the adjustment machine 3, the rolling of the mechanism natural sand gradation adjustment machine 3 drives the stepping hopper 38 to continuously lift and discharge the material, the steel ball and the mechanism natural sand to be adjusted are lifted to the top and fall at the same time, and the lower part The material of the stepping counterattack hopper itself is high manganese steel. When the steel ball falls to the counterattack surface, it can hit the machine-made natural sand on the counterattack surface that needs to be adjusted, and can also hit the mechanism natural sand on the adjacent counterattack surface after rebounding. And because the cylinder wall of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com