Rotary pressing plate for fixing felt on magnetic glass cleaner

A technology of rotating the pressing plate and wiping glass, which is applied in the field of daily cleaning products. It can solve the problems of easy loss of the buckle, unclean cleaning, and hand-grinding of the buckle, and achieve the effect of convenient picking and placing of the felt, clean cleaning effect, and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

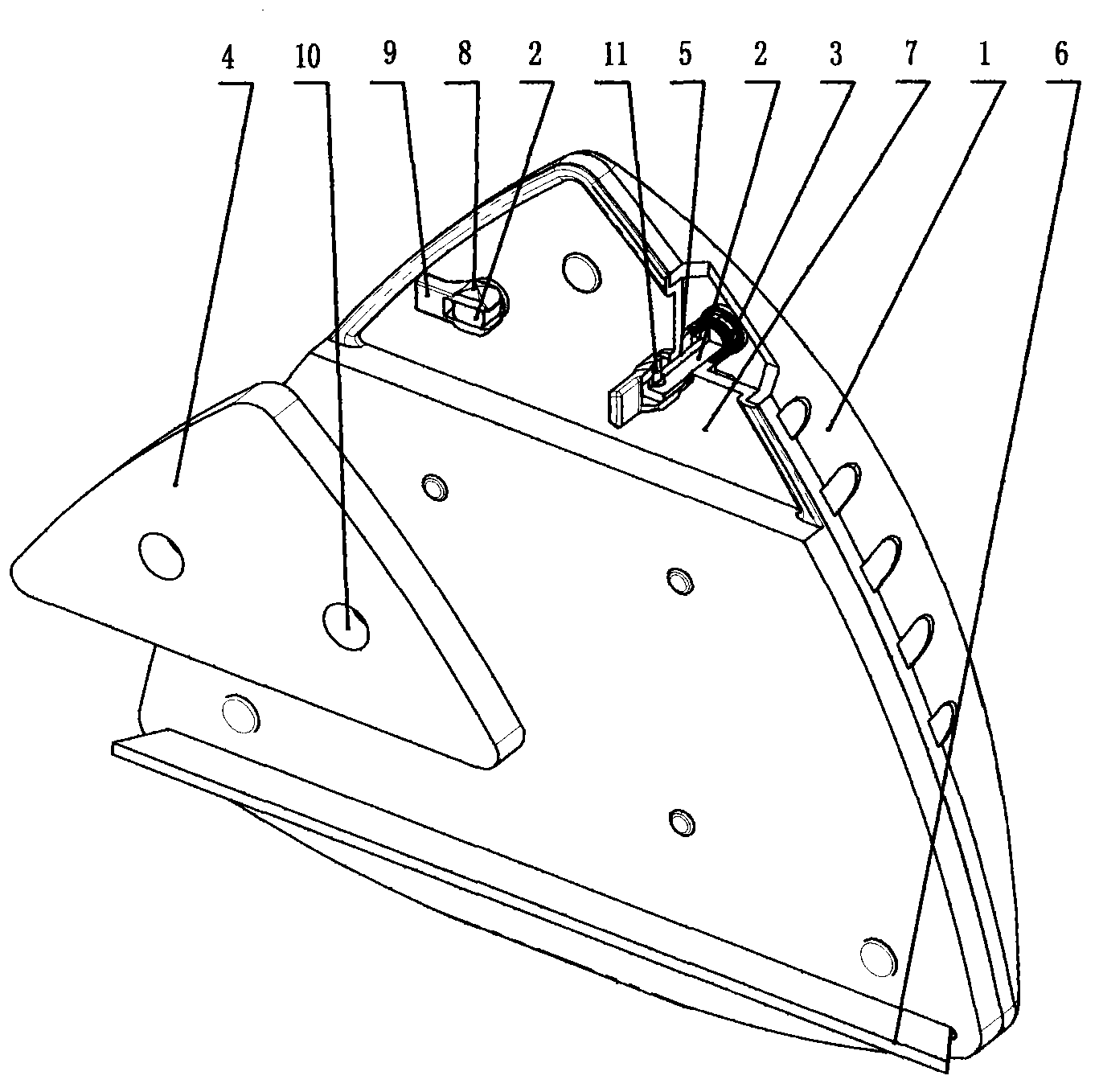

[0038] Such as figure 1 As shown, the magnetic glass cleaner is composed of a main magnetic wiper and a secondary magnetic wiper, which are used together, and are respectively adsorbed on the inner and outer surfaces of the glass. The upper cover 1 of the main magnetic wiper has a handle. When in use, it is placed on the indoor side of the glass, and the auxiliary glass wiper is placed on the outside of the glass. The upper cover 1 of the auxiliary glass wiper is provided with a hole to connect the wire rope. The ring buckle can lock the cord on the wrist to prevent the secondary magnetic force from rubbing off downstairs. Push the handle of the main magnetic wiper by hand, the main magnetic wiper drives the secondary magnetic wiper to move together, and the tail of the lower shell 7 is provided with a rubber scraper 6, which wipes on one side and cleans both sides.

[0039] The exterior of the magnetic glass wiper is an outer shell composed of an upper cover 1 and a lower sh...

Embodiment 2

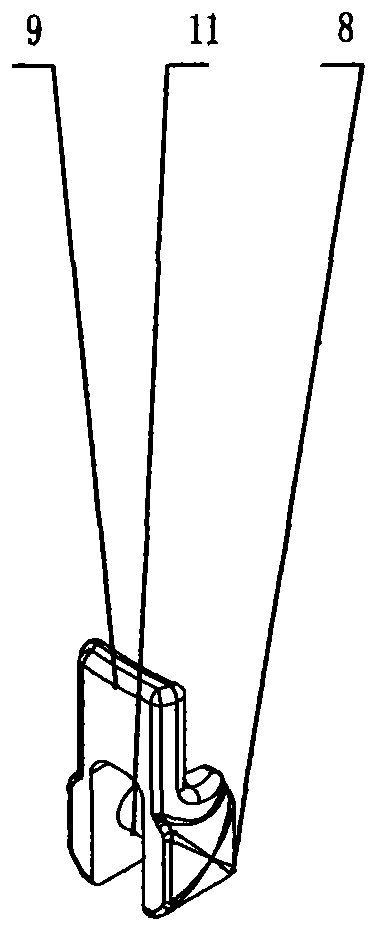

[0045] Such as Figure 4 , Figure 5 As shown, it is another rotary press plate used for fixing felt on a magnetic glass wiper of the present invention. The bottom surface of the lower shell 7 is provided with a chute 5 through which the inside and outside are connected, and a rotating pressing plate 8 is arranged in the chute 5 , and the rotating pressing plate 8 can rotate coaxially in the chute 5 .

[0046] Such as Figure 6 As shown, one end of the rotating pressing plate 8 of the present invention is eccentrically provided with a sheet-shaped eccentric pressing plate 9 , and the middle part of the rotating pressing plate 8 is a rotary shaft 18 . The middle part of the rotary shaft 18 can be slotted and provided with claws 17, and the middle part of the claws is S-shaped to enhance the elasticity of the claws 17.

[0047] Such as Figure 5As shown, a circular ring 16 is arranged inside the chute 5, and the circular ring 16 is obliquely arranged in the chute 5, and the ...

Embodiment 3

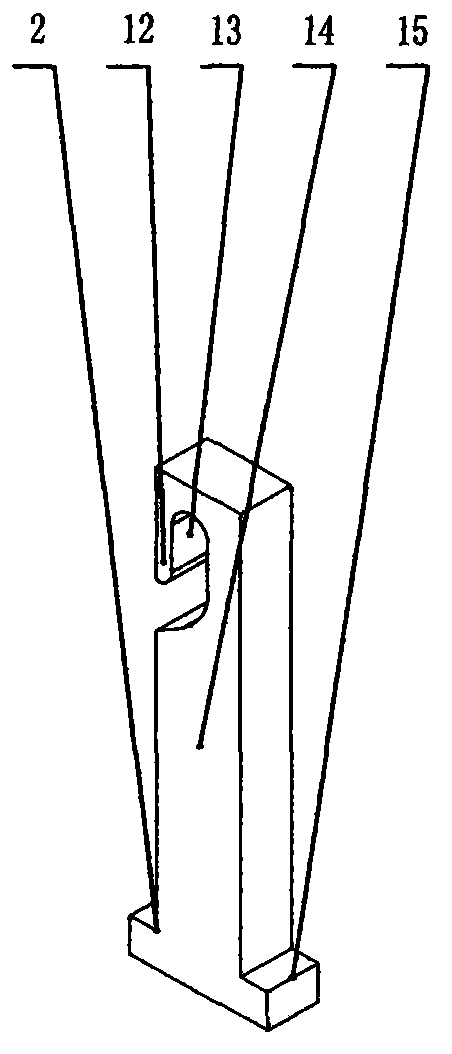

[0049] Such as Figure 7 , Figure 8 As shown, it is another rotary press plate used for fixing felt on a magnetic glass wiper of the present invention. The bottom surface of the lower shell 7 is provided with a chute 5 through which the inside and outside are connected, and a rotating pressing plate 8 is arranged in the chute 5 , and the rotating pressing plate 8 can rotate coaxially in the chute 5 .

[0050] Such as Figure 9 As shown, one end of the rotary platen 8 of the present invention is eccentrically provided with a sheet eccentric platen 9, and the eccentric platen 9 is in the shape of a strip, including but not limited to racetrack, ellipse or other artistic shapes with semicircular ends. The middle part of the rotary pressing plate 8 is a rotary shaft 18, and the axis of the eccentric pressing plate 9 and the rotary shaft 18 is arranged eccentrically. A spiral groove 20 can be slotted in the middle of the rotary shaft 18. The spiral groove 20 is a left-hand spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com