Nutritional healthcare ice cream containing vegetable protein, and making method thereof

A vegetable protein and ice cream technology, applied in frozen desserts, food science, applications, etc., can solve the problems of excessive cholesterol and fat intake, obesity, excess nutrition, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

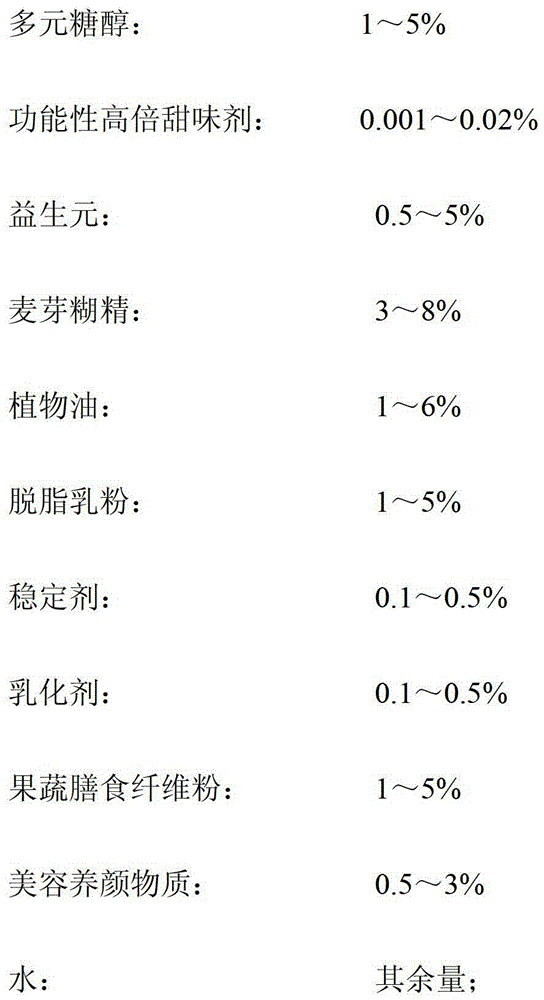

[0033] A kind of preparation method of vegetable protein nutritional health type ice cream, its component and mass percentage are:

[0034]

[0035]

[0036] According to the above components and mass percentages, taking the production of 100kg vegetable protein nutritional and health-care ice cream as an example, the production method is as follows:

[0037] 1) Pre-homogenization: After mixing 2kg of soybean protein, 4kg of soybean oil and 20kg of water, homogenize under a pressure of 150bar to obtain a soybean protein emulsion;

[0038] 2) Sterilization: Stir and mix the soybean protein emulsion prepared in step 1) and the remaining raw materials evenly, then sterilize in a sterilization tank at 90°C for 15 minutes,

[0039] 3) Homogenization: control the temperature to drop to 60°C after sterilization, and homogenize at 100bar for 7 minutes;

[0040] 4) Cooling and aging: Cool the homogenized material liquid in step 3) to 4°C, and age at this temperature for 2 hours;...

Embodiment 2

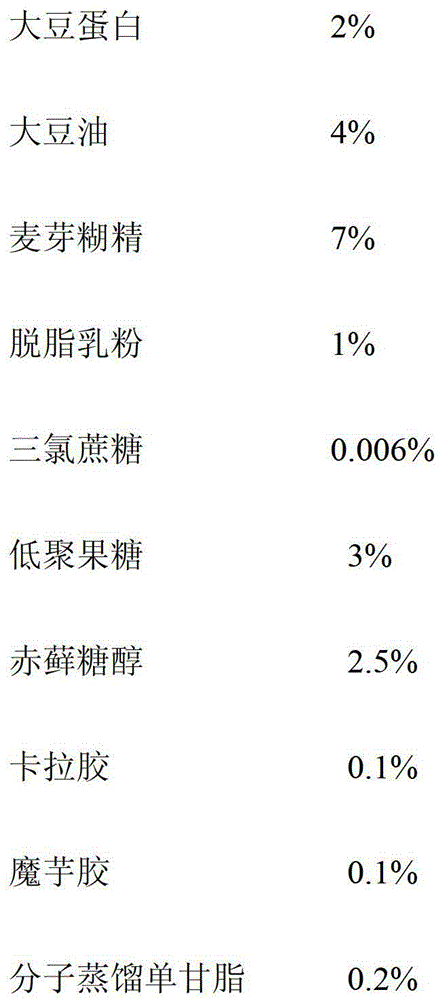

[0044] A kind of preparation method of plant protein nutrition and health type ice cream, its component and weight percentage are:

[0045]

[0046]

[0047] According to the above components and mass percentages, taking the production of 100kg vegetable protein nutritional and health-care ice cream as an example, the production method is as follows:

[0048] 1) Pre-homogenization: After mixing 5kg of soybean protein, 6kg of corn germ oil, and 50kg of water, homogenize under a homogenization pressure of 250bar to obtain soybean protein emulsion;

[0049] 2) Sterilization: After the soybean protein emulsion prepared in step 1) is fully stirred and mixed with the remaining raw materials, sterilize in a sterilization tank at 75°C for 30 minutes;

[0050] 3) Homogenization: control the temperature to drop to 65°C after sterilization, and homogenize at 250bar for 10 minutes;

[0051] 4) Cooling and aging: Cool the homogenized material liquid in step 3) to 4°C, and age at thi...

Embodiment 3

[0055]

[0056] According to the above components and mass percentages, taking the production of 100kg vegetable protein nutritional and health-care ice cream as an example, the production method is as follows:

[0057] 1) Pre-homogenization: Mix 1 kg of peanut protein, 1 kg of olive oil, 1 kg of sunflower oil, and 10 kg of water, and then homogenize at 200 bar to obtain a peanut protein emulsion;

[0058] 2) Sterilization: Stir and mix the peanut protein emulsion prepared in step 1) and the remaining components evenly, then sterilize in a sterilization tank at 80°C for 25 minutes;

[0059] 3) Homogenization: control the temperature to drop to 65°C after sterilization, and homogenize at 200bar for 8 minutes;

[0060] 4) Cooling and aging: Cool the homogenized material liquid in step 3) to 4°C, and age at this temperature for 12 hours;

[0061] 5) Freezing: Use a continuous freezer to freeze the aged liquid in step 4), and stop freezing when the expansion rate reaches 85%;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com