Internal radiation ring type static speed-adjusting permanent magnetic coupling

A technology of permanent magnetic coupling and internal radiation, which is applied in the direction of electrical components, electromechanical devices, emergency protection circuit devices, etc., can solve the problems that the rigid coupling cannot buffer and absorb shocks, and cannot compensate the relative displacement of two axes, so as to achieve overload Slip protection, speed regulation, energy saving, reduced motor capacity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

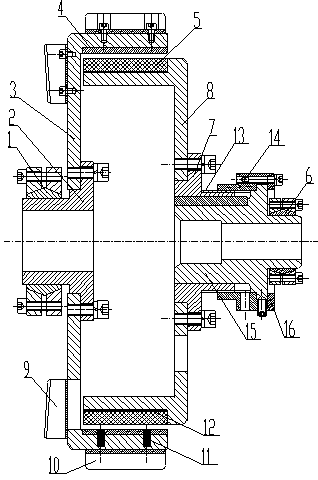

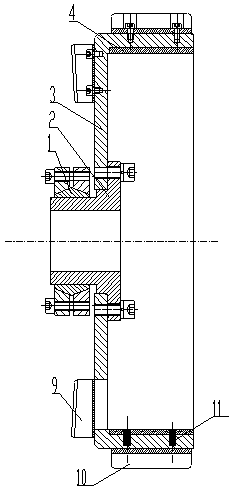

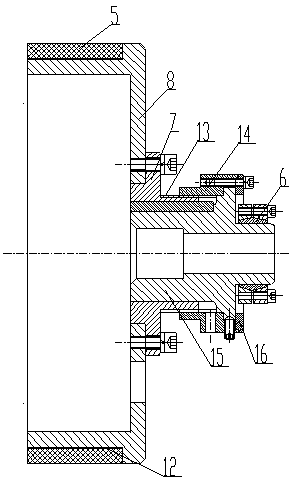

[0039] Such as Figure 1-8 Shown:

[0040] The invention adopts an outer single-ring induction device with a fixed radial air gap size, a radiation-oriented ring-type inner overall magnetic ring with an optimized structure for effective size and a high-efficiency heat dissipation system, supplemented by a static speed regulating mechanism. The non-contact torque transmission between the motor and the load is realized through magnetic coupling, and the high-efficiency heat dissipation is used to ensure the stability of the magnetic force of the system. Realize automatic slip protection for motor and load equipment when the load is overloaded. In the static state, the speed regulation of the load and the energy saving of the motor are realized through the meshing surface adjustment mechanism. The specific structure and technical scheme of the inner radiation ring type static speed-regulating permanent magnet coupling are as follows: 1 conductor outer rotor I: motor shaft expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com