Nuclear electromagnetic pulse resisting cable and manufacturing process thereof

An anti-nuclear electromagnetic pulse and cable technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, and bendable cables, can solve the problems of no relevant standards for anti-nuclear electromagnetic pulse cables, etc., and achieve wear resistance and softness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

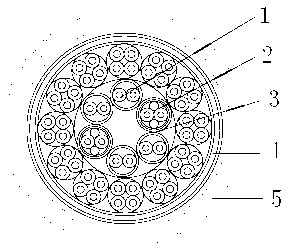

[0029] Embodiment 1, the preparation technology of anti-nuclear electromagnetic pulse cable product, including

[0030] 1) The tinned round copper stranded wire or the silver plated round copper stranded wire is twisted by the wire bundler as conductor 1;

[0031] 2) Use high temperature extruder equipment to extrude high temperature resistant fluoroplastic insulation 2;

[0032] 3) Use a high-speed untwisting machine to twist the insulated wire cores, wrap the PTFE microporous tape after the twisting, and add a filling core (8mm×0.10mm PTFE microporous tape to twist a filling rope with a diameter of 0.85mm), and use it to form a cable. The machine twists the control wires together;

[0033] 4) Then wrap the single-sided aluminum-plastic composite tape, and the outer layer is braided with tin-plated round copper wire as a separate shield;

[0034] 5) The cable forming machine twists the data line and the control line together;

[0035] 6) Wrap a layer of 300T conductive clo...

Embodiment 2

[0041] Embodiment 2, the preparation technology of anti-nuclear electromagnetic pulse cable product, including

[0042] 1) The tinned round copper stranded wire or the silver plated round copper stranded wire is twisted by the wire bundler as conductor 1;

[0043] 2) Use high temperature extruder equipment to extrude high temperature resistant fluoroplastic insulation 2;

[0044] 3) Use a high-speed untwisting machine to twist the insulated wire cores, wrap the PTFE microporous tape after the twisting, and add a filling core (8mm×0.10mm PTFE microporous tape to twist a filling rope with a diameter of 0.85mm), and use it to form a cable. The machine twists the control wires together;

[0045] 4) Then wrap the single-sided aluminum-plastic composite tape, and the outer layer is braided with tin-plated round copper wire as a separate shield;

[0046] 5) The cable forming machine twists the data line and the control line together;

[0047] 6) Wrap a layer of 300T conductive clo...

Embodiment 3

[0053] Embodiment 3, the preparation technology of anti-nuclear electromagnetic pulse cable product, including

[0054] 1) The stranded tinned round copper stranded wire or the tinned round copper stranded wire is the conductor 1;

[0055] 2) Use high temperature extruder equipment to extrude high temperature resistant fluoroplastic insulation 2;

[0056] 3) Use a high-speed untwisting machine to twist the insulated wire cores, wrap the PTFE microporous tape after the twisting, and add a filling core (8mm×0.10mm PTFE microporous tape to twist a filling rope with a diameter of 0.85mm), and use it to form a cable. The machine twists the control wires together;

[0057] 4) Then wrap the single-sided aluminum-plastic composite tape, and the outer layer is braided with tin-plated round copper wire as a separate shield;

[0058] 5) The cable forming machine twists the data line and the control line together;

[0059] 6) Wrap a layer of 300T conductive cloth in the left direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com