Dry-mixed mortar storage mixer one-way monitoring system and monitoring method

A dry-mixed mortar and monitoring system technology, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems that the dry-mixed mortar storage mixer cannot be monitored intuitively, and cannot meet the needs of industrial monitoring, so as to achieve development Low cost, simple implementation, and convenient deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

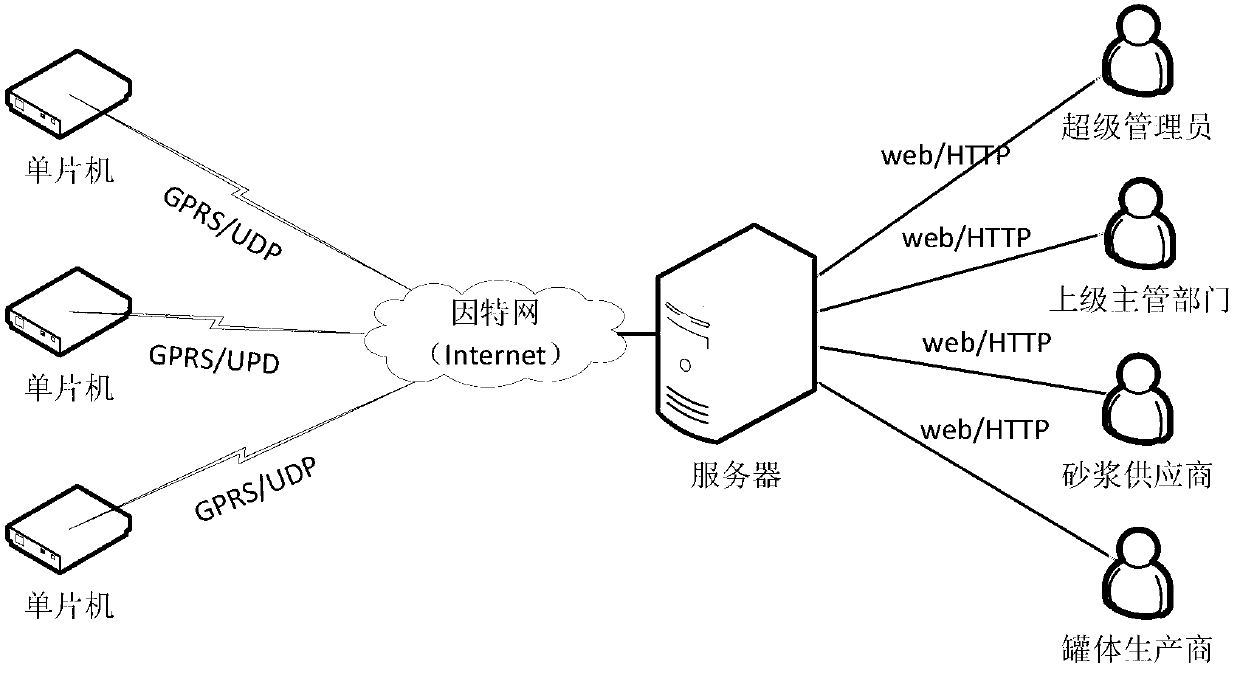

[0032] Such as figure 1 As shown, the one-way monitoring system of the dry-mixed mortar storage mixer of the present invention complies with the ISO standard, implements the application layer, and transmits data based on the UDP transmission protocol. The system includes a dry-mixed mortar storage mixer monitoring single-chip microcomputer and a remote server.

[0033] Among them, the single-chip microcomputer collects the operation status of the dry-mixed mortar storage mixer equipment on the construction site and the current material status. The single-chip microcomputer contains a GPRS hardware module, and sends the collected information to the remote remote server through this module; Industrial large-scale monitoring, the remote server is connected to the single-chip microcomputers deployed at the construction production site at the end of all dry-mixed mortar storage mixers to form a one-way monitoring system for dry-mixed mortar storage mixers, working together, the remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com