An artificial fouling characteristics test system and its operating method

A characteristic test and artificial fouling technology, applied in the field of artificial fouling characteristic test system, can solve the problems of cumbersome sampling steps, hidden safety hazards, and low measurement reliability, so as to save manpower and material resources, wide research scope, and prevent environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

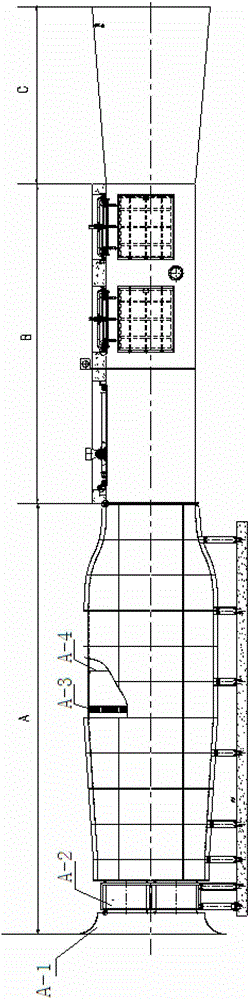

[0051] A kind of artificial fouling characteristics test system proposed in this embodiment, the front view of its overall structure is as follows figure 1 As shown, it mainly includes three parts, A—wind source power section; B—test section; C—air duct diffusion and dust removal section.

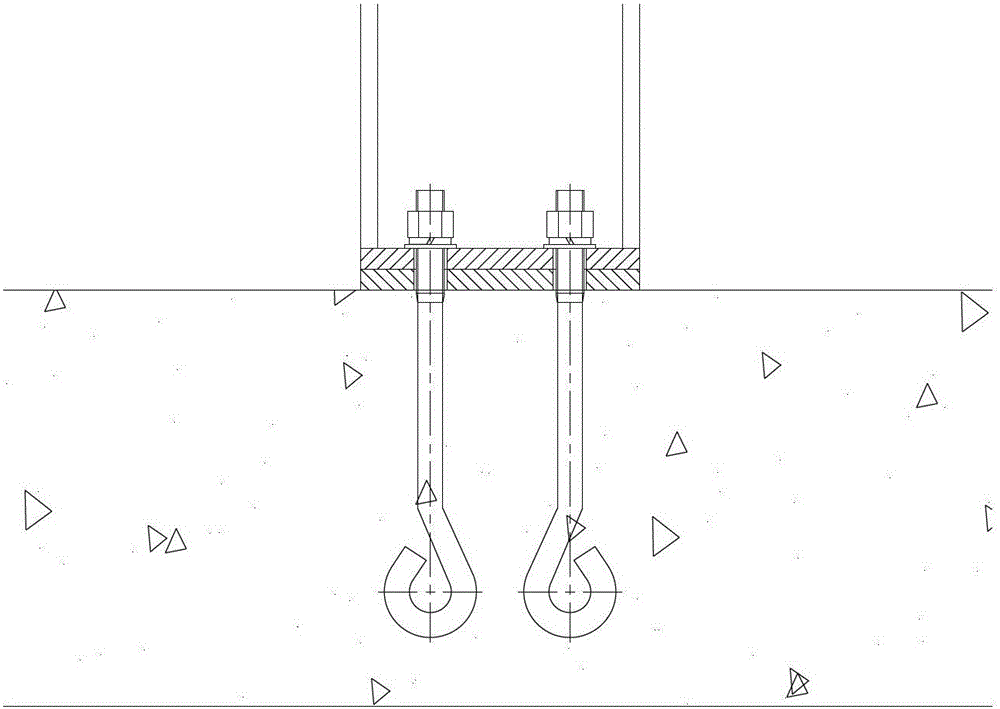

[0052] The wind source power section is used to provide natural wind to the test section; there is a base at the bottom to support the entire test system. The connection structure diagram between the base and the foundation is shown in image 3 As shown, the base is welded by H-shaped steel, and the base and the foundation are connected by M20 expansion bolts.

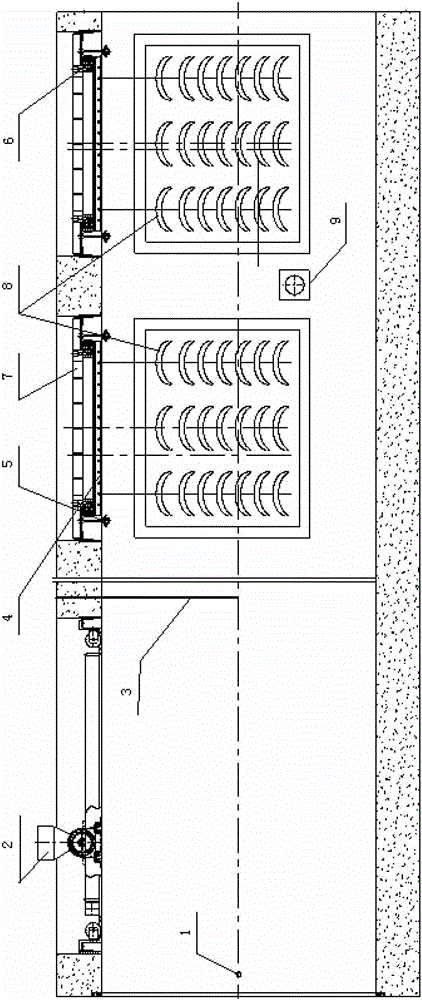

[0053] The test section is the main test part of the artificial pollution characteristics test system, which is mainly used to simulate the insulator string 8 on the actual pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com