Gas stove head device

A stove and gas technology, which is applied in the field of gas stove head devices, can solve the problems of yellow fire, incomplete combustion, easy expansion and deformation of the gas stove head, and achieve the elimination of yellow fire, large combustion range and balanced pressure distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

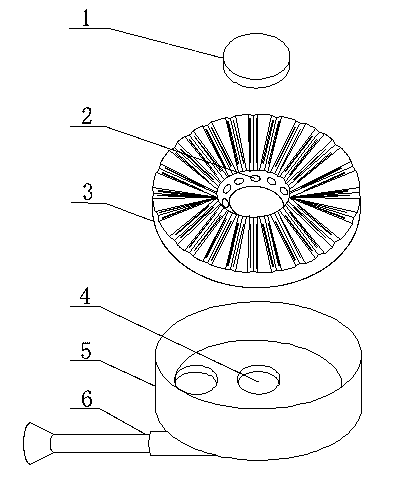

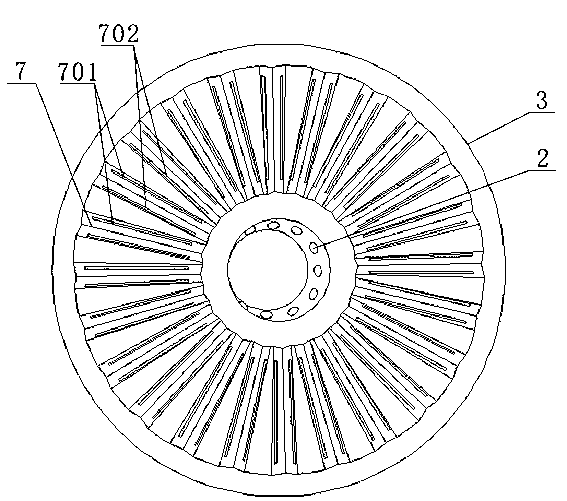

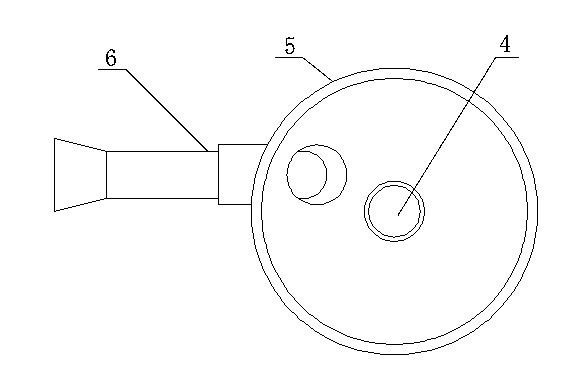

[0023] Such as figure 1 As shown, a gas stove burner device includes a base 5, a cover body 3 with a through hole in the center, and a sealing plug 1 installed at the through hole. The interior of the base 5 forms an accommodating space with an upper opening, and the cover The body 3 is mounted on the opening on the top of the base 5. The cover 3 is an annular structure with a conical inner concave surface. The wall of the through hole in the center of the cover 3 is provided with blind holes 2 distributed in a circle. The cover 3 There are V-shaped grooves 7 arranged at intervals on the upper surface of the V-shaped groove, and the slopes on both sides of the V-shaped groove 7 are 45°. The slopes on both sides of each V-shaped groove are respectively provided with gas grooves 701 and air grooves 702 , the air groove 702 communicates with the inside of the blind hole 2, the gas groove 701 runs through the upper and lower surfaces of the cover body 3, and a slope 8 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com