Flexible start speed adjusting device capable of realizing belt-type conveyor on-load power isolation

A belt conveyor and flexible start technology, applied in the direction of conveyors, transmission devices, fluid transmission devices, etc., can solve the problems of design and cost control adverse effects, belt conveyor adverse effects, and reduce load acceleration torque, etc., to achieve The effect of reducing the difficulty of technical realization, improving the continuous operation performance and reducing the braking torque requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

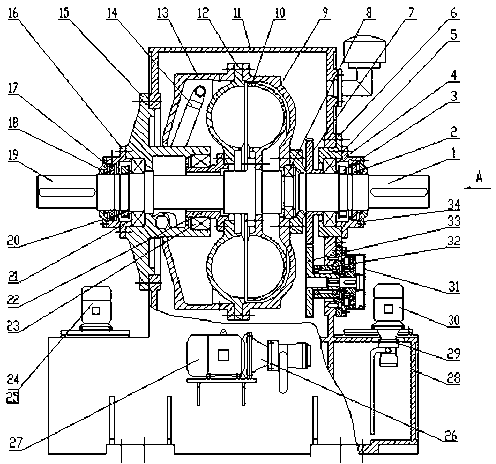

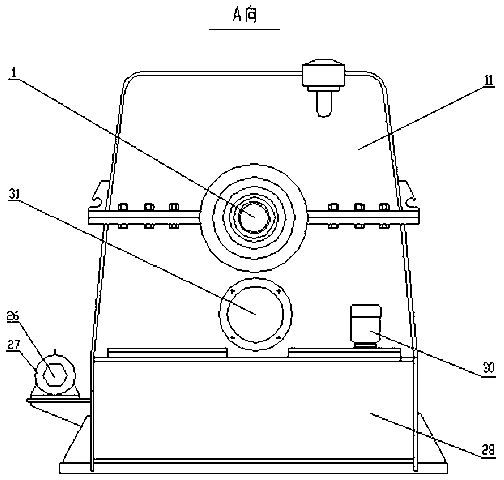

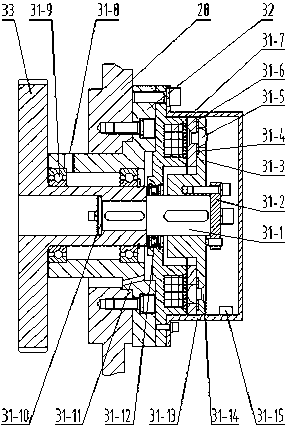

[0045] like figure 1and figure 2 Shown, the present invention comprises box body 28 and box cover 11, and box body 28 and box cover 11 are fixedly connected together with bolts, and left and right 2 circular holes are processed on the sub-case surface of box body 28 and box cover 11, and The left end face of the left round hole is equipped with an oil discharge cavity 15, the oil discharge cavity 15 is fixedly connected with the box body 28 and the case cover 11 with bolts, and a turbine shaft 19 is installed in the oil discharge cavity 15, and the turbine The shaft 19 is equipped with a turbine bearing 21, a second round nut 20, a first left end cover 16, a turbine tachometer gear 17 and a second left end cover 18, and the first left end cover 16 and the oil discharge cavity 15 on the right are connected by bolts For fixed connection, the shoulder end surface on the right side of the first left end cover 16 is pressed against the left end surface of the outer ring of the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com