Multi-stage centrifugal compressor constant pressure control device based on PLC

A centrifugal compressor and constant pressure control technology, which is applied in pump control, mechanical equipment, non-variable pumps, etc., can solve the problems that the harmonic influence of the power grid cannot be ignored, the pressure output fluctuates greatly, and the energy consumption loss is large. Achieve the effects of avoiding the occurrence of surge danger, ensuring the response speed, and ensuring energy-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

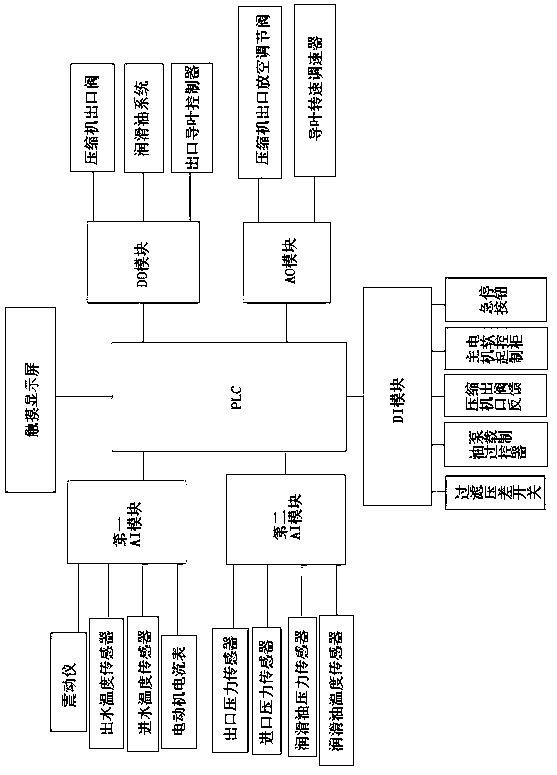

[0031] Embodiment 1, a PLC-based multi-stage centrifugal compressor constant pressure control device, the control device includes a PLC, and the PLC communicates with the touch screen, the first AI module, the second AI module, the DI module, and the DO through signal lines respectively. Module and AO module connection;

[0032] The first AI module communicates with the vibration meter installed on the compressor gearbox, the outlet water temperature sensor installed at the cooling water outlet of the cooler, the inlet water temperature sensor installed at the cooling water inlet of the cooler, and the motor of the compressor through the signal line respectively. ammeter connection;

[0033] The second AI module is respectively connected with the outlet pressure sensor installed at the outlet of the compressor, the inlet pressure sensor installed at the inlet of the compressor, the lubricating oil pressure sensor of the gearbox, and the lubricating oil temperature sensor of th...

Embodiment 2

[0037] Embodiment 2, in the PLC-based multi-stage centrifugal compressor constant pressure control device described in Embodiment 1: the control software of the PLC adopts modular design, and adopts a combination of open and closed loops and a fuzzy PID control method.

Embodiment 3

[0038] Embodiment 3, in the PLC-based multi-stage centrifugal compressor constant pressure control device described in Embodiment 1 or 2: the PLC is also provided with a communication port to communicate with an external computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com