Steel PDC drilling bit with erosion-proof tooth cavities

An anti-erosion and tooth cavity technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of increasing the drilling resistance of the drill bit, wearing the back of the drill bit blade, limiting the mechanical penetration rate of the drill bit, etc., so as to improve rock breaking efficiency, avoiding drill failure, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

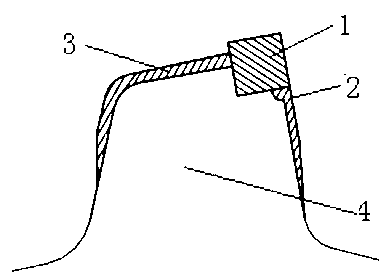

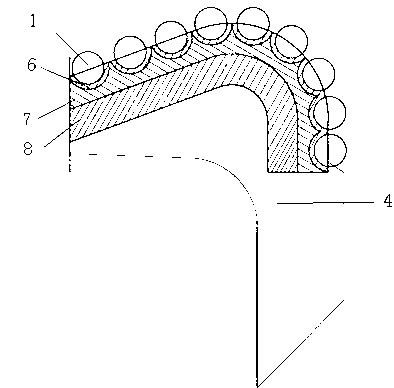

[0028] The first example is figure 1 , 2 , 3, including the drill bit body 10 and the curved blade 4 that is arranged on the periphery of the drill body and the end surface protruding outward at intervals, between the blades is a chip removal groove, and a nozzle 5 is arranged in the chip removal groove, and the front of the blade blade A tooth cavity is set up above, and the tooth cavity is a large semi-circular arc hole, and a cavity groove is provided along the edge of the tooth cavity at the front end of the tooth cavity. The depth is 3mm, the radial depth is 4mm, and the wear-resistant layer 6 is welded in the groove. The tooth cavities are arranged at intervals along the outer contour of the blade front, and are distributed in the inner cone, nose, shoulder and gauge section of the blade, and cylindrical composite sheet cutting teeth 1 are installed in the toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com