Motor rotor surface pickling and deburring machine

A motor rotor and surface acid technology, which is applied in the field of motor manufacturing, can solve the problems of affecting the service life of the rotor, affecting the performance of the motor, and affecting the pickling effect, so as to improve the treatment effect and production efficiency, improve the production efficiency, and improve the pickling treatment effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

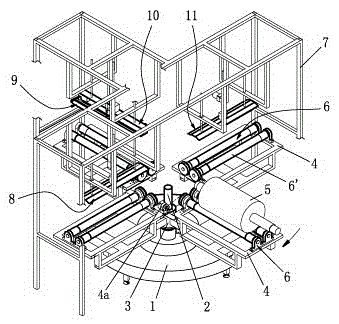

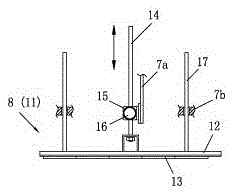

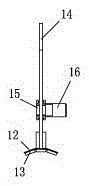

[0024] Referring to the accompanying drawings, a base 1 is provided, and a vertical shaft 2 is provided at the center of the base 1;

[0025] The vertical shaft 2 is provided with a turret 3 driven by a first driving mechanism, the vertical shaft at the center of the turret 3 is sleeved on the vertical shaft 2, and the first driving mechanism drives the turret 3 around the vertical shaft 2 To rotate, the first driving mechanism is arranged in the base 1 (not shown in the figure), including a motor and a gear transmission component, and the output of the transmission component cooperates with the vertical bushing on the turret 3 to realize the transmission of driving torque;

[0026] The turret 3 is provided with at least four station stands 4, and each station stand 4 is provided with an idler assembly 6 for supporting the motor rotor 5, and the two idler rollers 6' of the idler assembly 6 are Driven by the second drive mechanism can produce the same rotation;

[0027] The tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com