Equipment and method for growing silicon carbide film

A technology of thin film growth and silicon carbide, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of difficult deployment and high cost, and achieve the effects of easy deployment, increased efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the present invention more clear, the exemplary embodiments of the present invention will be described below in conjunction with the accompanying drawings. For the sake of clarity and brevity, actual embodiments are not limited to the technical features described in the specification. It should be understood, however, that in improving any one of the actual embodiments described, multiple embodiment-specific decisions must be made to achieve the improver's specific goals, for example, compliance with industry-related and business-related constraints, described Limits vary from embodiment to embodiment. Moreover, it should be understood that the effects of the aforementioned improvements, even if very complex and time-consuming, are still routine technical means for those skilled in the art who are aware of the benefits of the present invention.

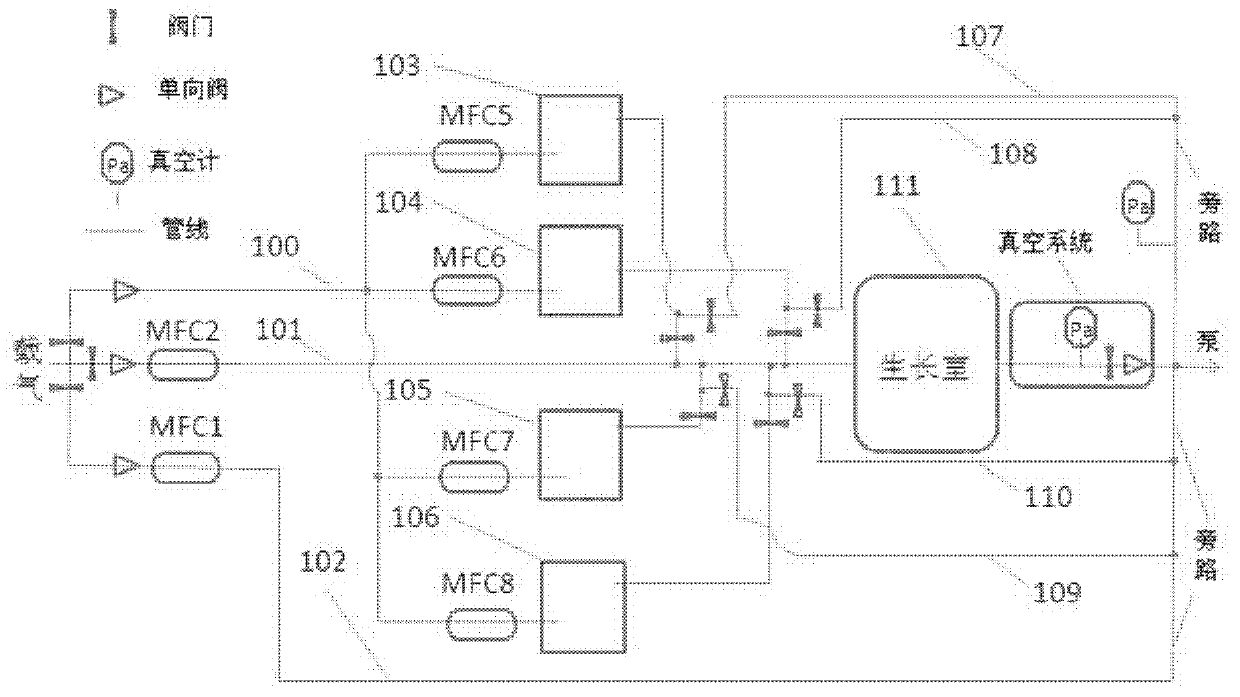

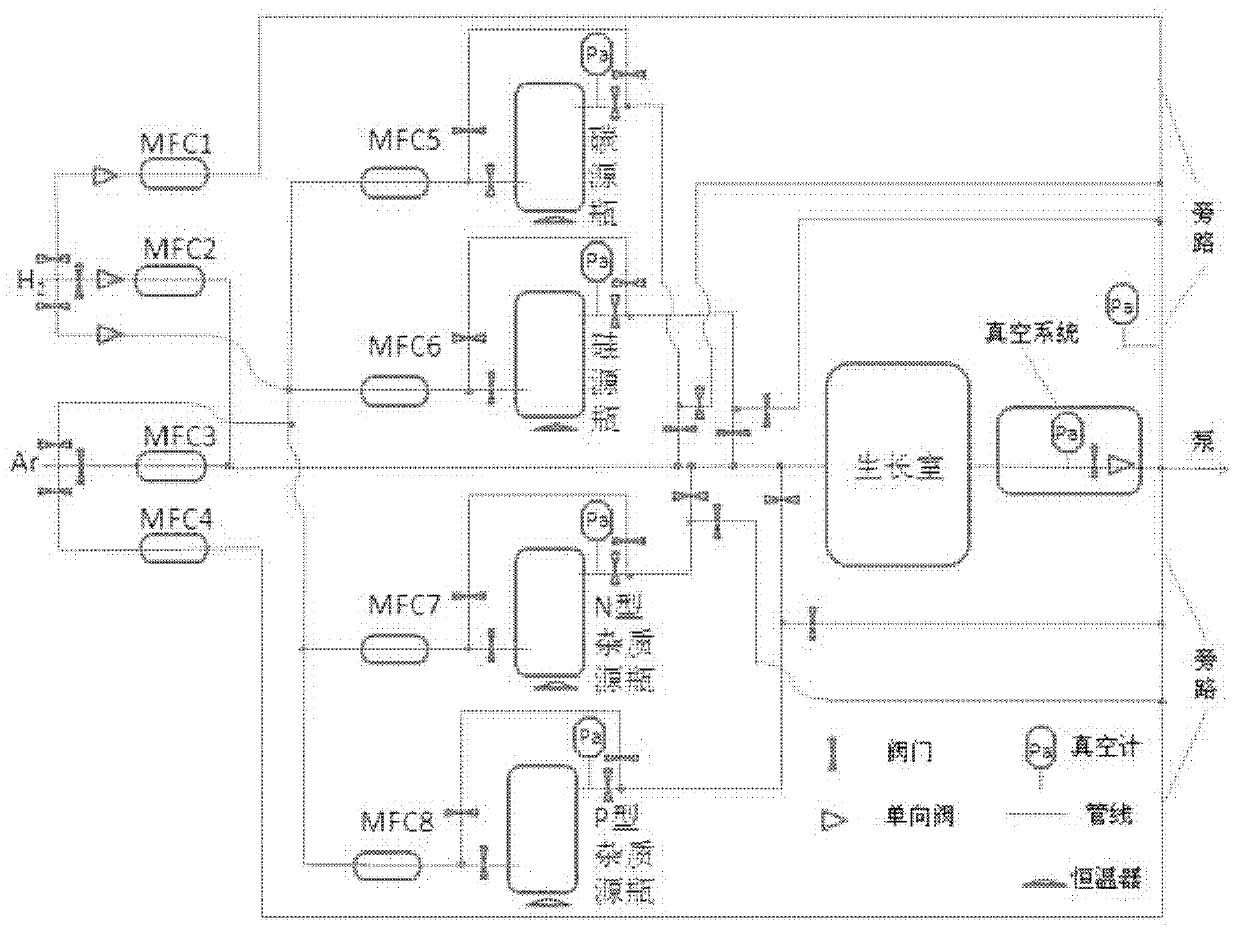

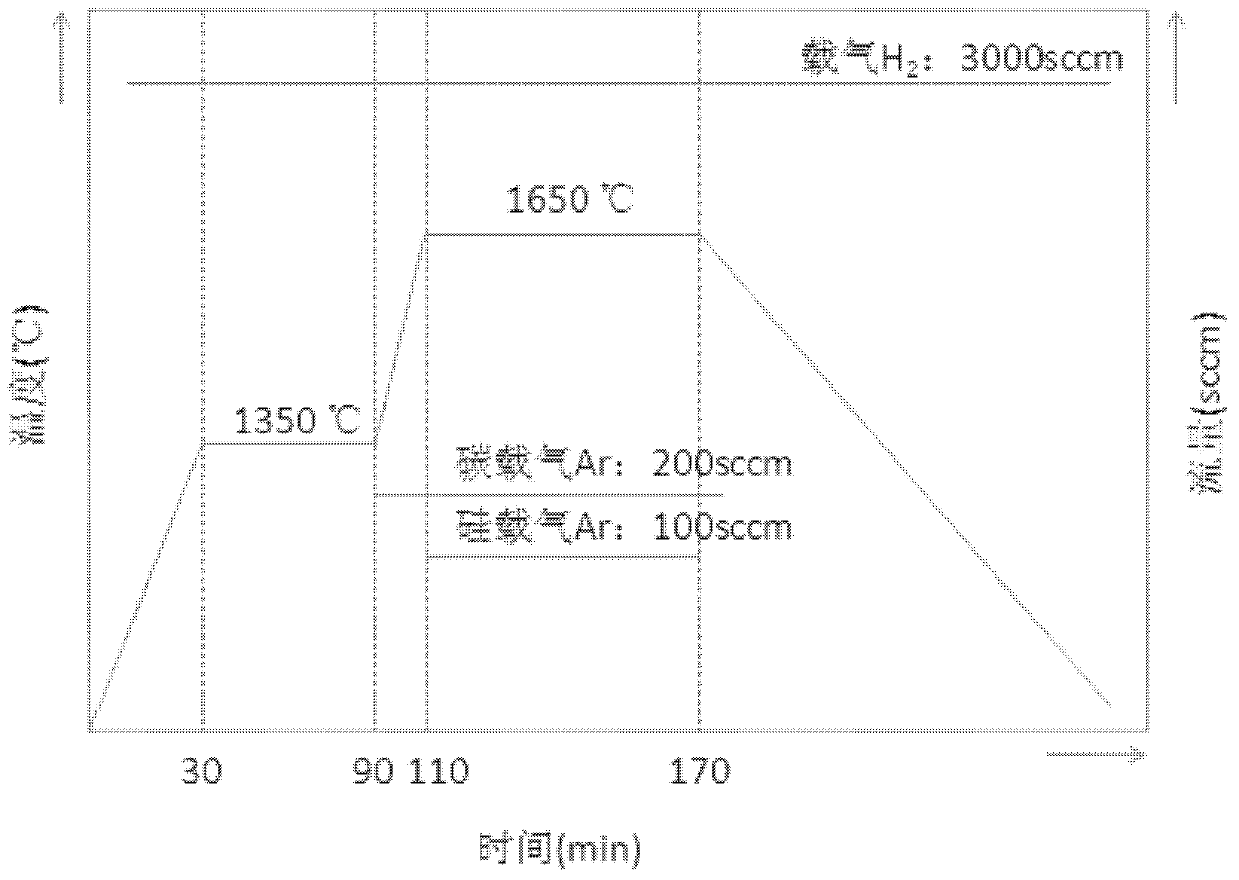

[0037] figure 1 A schematic structural diagram of a sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com