Surface printed solidified matte ink and preparation method thereof

A matte ink and ink technology, applied in ink, household utensils, applications, etc., can solve the problems of inability to achieve embellishment effect, difficult to achieve precise hollowing of matte film, etc., achieve obvious matte effect, beautify packaging patterns, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A surface-printing and curing matte ink is formed by adding a curing agent to a base material of an ink in a proportion of 6-10% and stirring evenly.

[0012] n-propyl ester 23, butyl acetate 10, polyurethane resin 8, aldehyde ketone resin 10, leveling agent 1, nitrocellulose 40, ternary chloride 7, defoamer 0.5, dispersant 0.5.

[0013] The components of the above raw materials are 100 parts.

[0014] The preparation method is to first grind and dissolve the n-propyl ester, butyl acetate, polyurethane resin, ternary chloride ester and aldehyde-ketone resin of the above components for 4-6 hours, and the fineness is less than 15um; Slurry and disperse at high speed, the rotating speed is 900-1500r / min, and disperse at high speed for 4 hours; filter after passing the review, and the mesh pattern is less than 120 mesh; after acceptance, the finished product is packaged to obtain the ink base material. The matte ink base material can be used for printing after adding 6-10%...

Embodiment 2

[0016] A surface-printing and curing matte ink is formed by adding a curing agent to a base material of an ink in a proportion of 6-10% and stirring evenly.

[0017] 20 n-propyl ester, 11 butyl acetate, 7 polyurethane resin, 8 aldehyde and ketone resin, 0.5 leveling agent, 45 nitrocellulose, 8 ternary chloride, 0.2 defoamer, 0.3 dispersant.

[0018] The components of the above raw materials are 100 parts.

[0019] The preparation method is the same as that in Example 1, so it will not be repeated.

Embodiment 3

[0021] A surface-printing and curing matte ink is formed by adding a curing agent to a base material of an ink in a proportion of 6-10% and stirring evenly.

[0022] n-Propyl Ester 26, Butyl Acetate 13, Polyurethane Resin 5, Aldehyde and Ketone Resin 12, Leveling Agent 1.5, Nitro-Gloss 35, Chlorine 7, Defoamer 0.3, Dispersant 0.2

[0023] The components of the above raw materials are 100 parts.

[0024] The preparation method is the same as that in Example 1, so it will not be repeated.

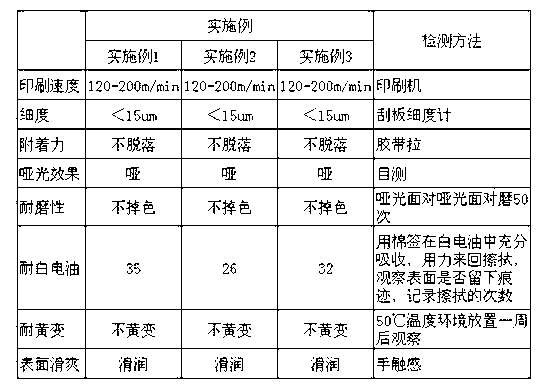

[0025] The performance physicochemical index test table of above-mentioned each embodiment gained table printing and curing matte ink is as follows:

[0026] --

[0027] It can be seen from the test results in the table that the surface-printing cured matte ink obtained in the embodiment of the present invention has the characteristics of excellent touch, pressure resistance, light resistance, yellowing resistance, strong adhesion, smooth surface and matte effect. Obviously, the printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com