Method for assembling metal nanometer clusters of lamellar structure or structure similar to bipyramidal in high boiling point solvents

A technology of high boiling point solvents and metal nanoclusters, applied in nanotechnology and other fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

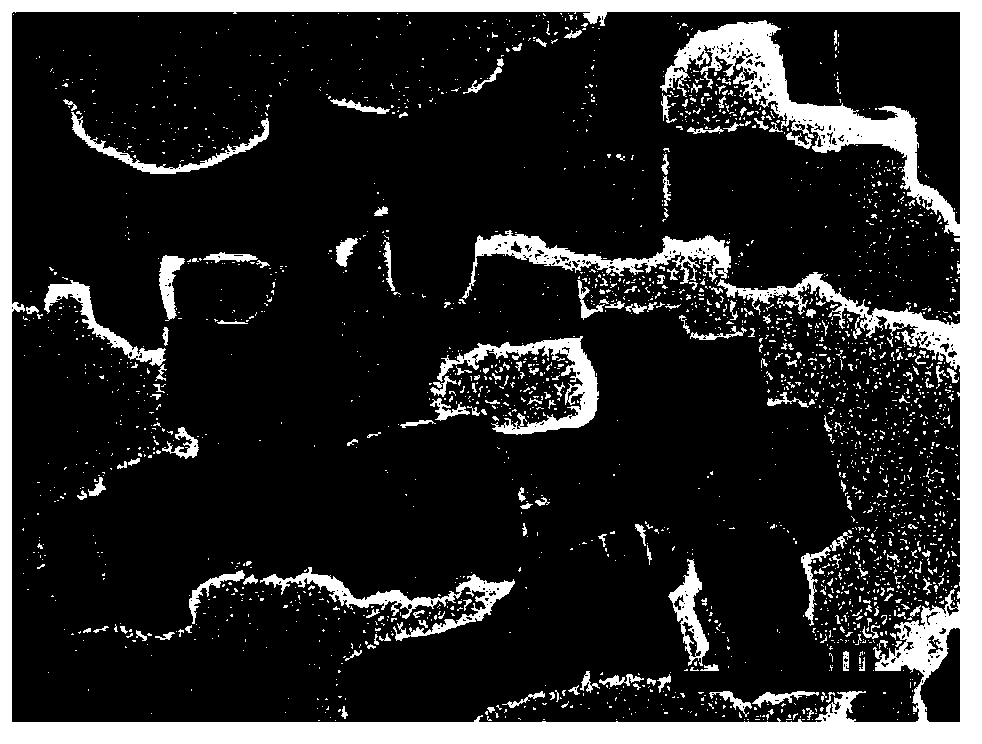

[0020] Add 2ml of dibenzyl ether into a 10ml beaker, and dissolve 0.486mmol of HAuCl 4 4H 2 O, under magnetic stirring at room temperature, add 2.1 mmol of dodecyl mercaptan dropwise, and then keep stirring for 1 h to obtain dodecyl mercaptan-stabilized metal nanoclusters (Au 15 ). The obtained gold nanocluster solution was added to a three-necked bottle with 15ml of liquid paraffin, and the mixed solution was slowly heated (6°C / min) to 140°C under vacuum, and then reacted at 140°C for 1h. Such as figure 1 As shown, a lamellar assembly ranging from 1.2 to 1.8 nm in thickness, 100 to 200 nm in width and 300 to 1000 nm in length was obtained.

Embodiment 2

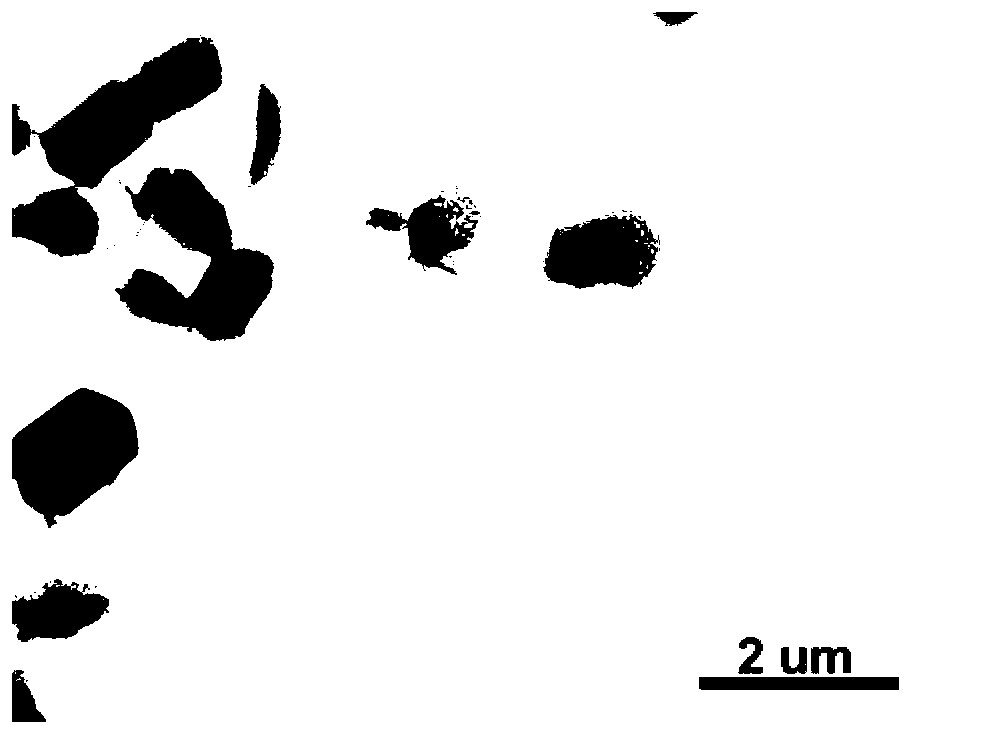

[0022] Add 2ml of dibenzyl ether into a 10ml beaker, and dissolve 0.486mmol of HAuCl 4 4H 2 O, under magnetic stirring at room temperature, 2.1 mmol of dodecyl mercaptan was added dropwise, and then kept stirring for 1 h to obtain dodecyl mercaptan-stabilized metal nanoclusters. Add the obtained gold nanocluster solution into a three-necked bottle with 15ml of liquid paraffin, and the mixed solution is slowly heated (6°C / min) to 140°C under N2 conditions, and then reacted at 140°C for 1h . Such as figure 2 As shown, a regular hexagonal sheet assembly with a thickness of 1.2-1.8nm and a size of 1um was obtained.

Embodiment 3

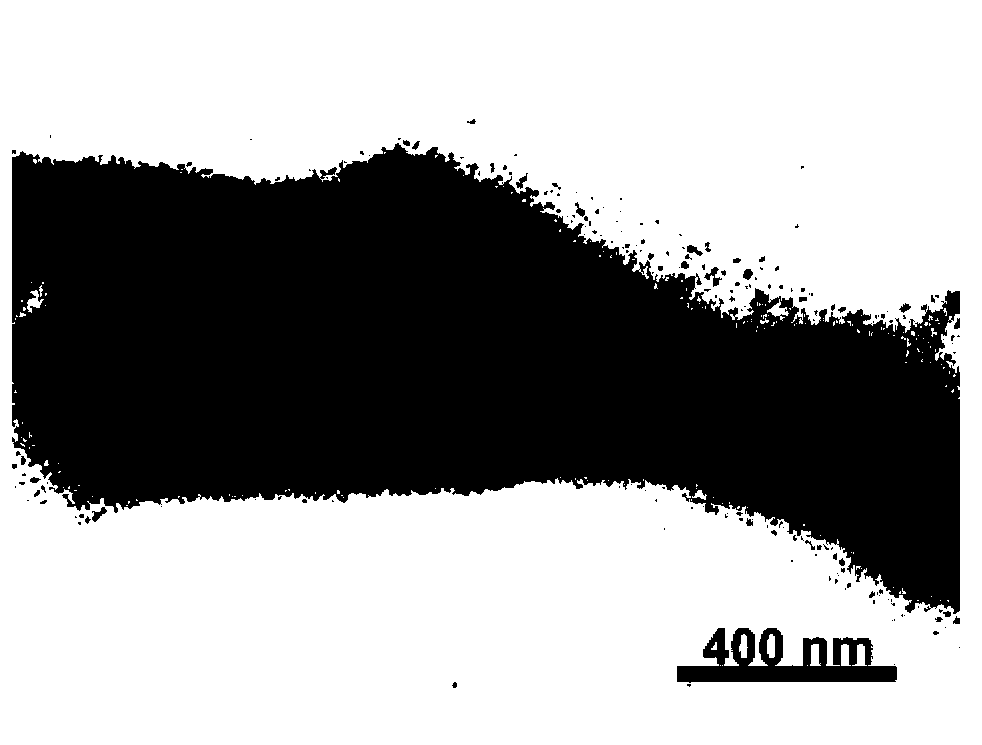

[0024] Add 2ml of dibenzyl ether into a 10ml beaker, and dissolve 0.486mmol of CH 3 In COOAg, under magnetic stirring at room temperature, 2.1 mmol of dodecyl mercaptan was added dropwise, and then kept stirring for 1 h to obtain dodecyl mercaptan-stabilized metal nanoclusters. The obtained gold nanocluster solution was added to a three-necked bottle with 15ml of liquid paraffin, and the mixed solution was slowly heated (6°C / min) to 140°C under vacuum, and then reacted at 140°C for 1h. Such as image 3 As shown, a lamellar structure with a thickness of 10-20 nm, a width of 100-500 nm and a length of 500-1000 nm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com