Guard ring for preventing short circuit of test structure, manufacturing method thereof, and package testing method

A technology for testing structures and manufacturing methods, applied in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, circuits, etc. The effect of moisture entering the test structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

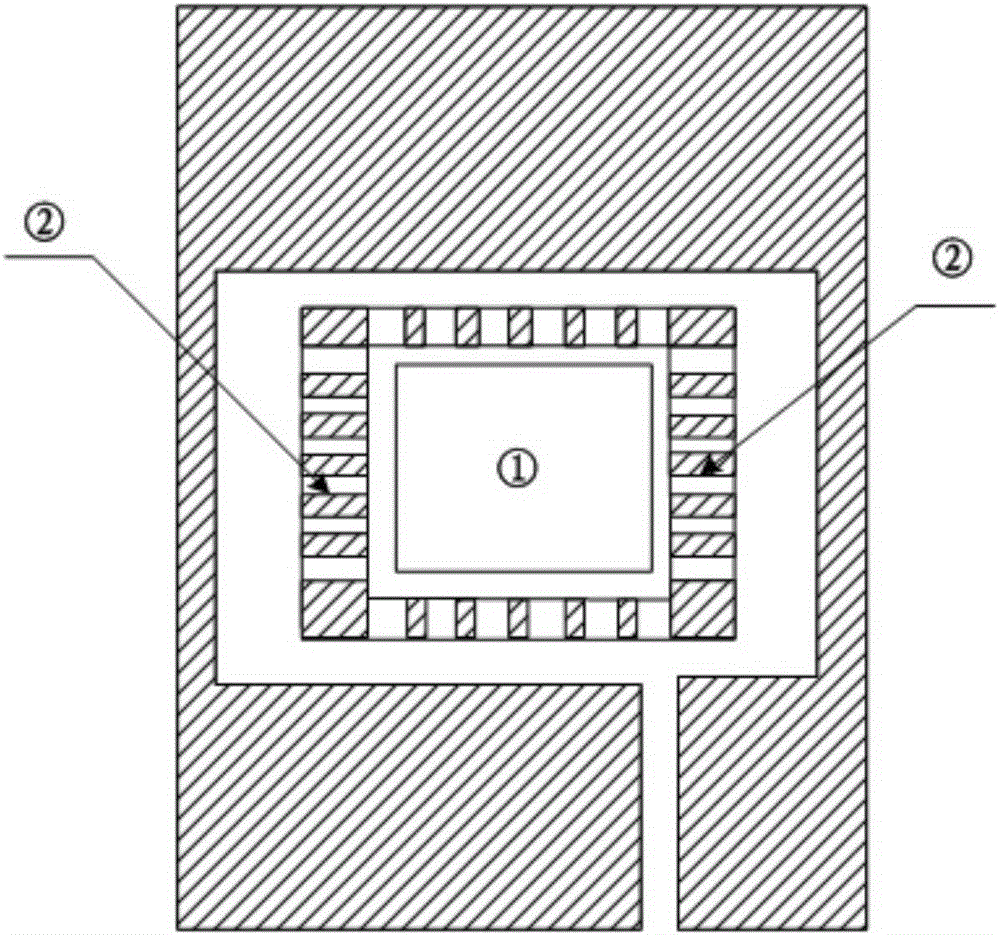

[0042] by Figure 7 The flow chart shown in the example, combined with Figure 8 , and describe in detail the manufacturing method of a guard ring for preventing short circuit of the test structure provided by the present invention.

[0043] In step 1, a low-K dielectric layer 100 is formed, grooves are opened in the low-K dielectric layer, and metal is filled to form an interconnection layer with a metal belt-shaped surrounding structure. The interconnection layer formed for the first time is used as the bottom interconnection layer 201 .

[0044]In step 2, step 1 is repeated, and the interconnection layer as described in step 1 is formed on the underlying interconnection layer, and the interconnection layer formed for the second time is used as the bottom metal via 202; and step 1 is repeated, and the bottom metal via The interconnection layer as described in step 1 is formed on the upper layer, and the interconnection layer formed for the third time is used as the sub-bott...

Embodiment 2

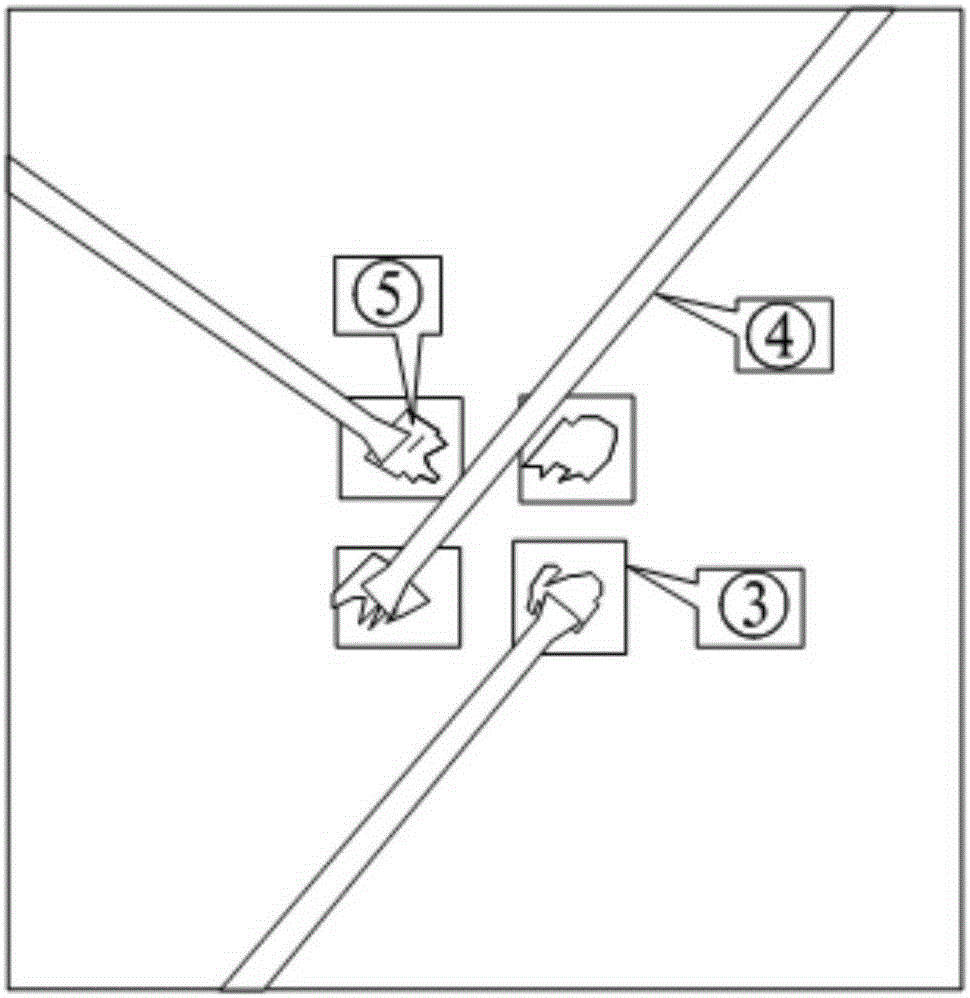

[0050] by Figure 9 The flow chart shown in the example, combined with Figure 10 , a package testing method for preventing a short circuit of a test structure provided by the present invention is described in detail.

[0051] In step 10, the guard ring 500 for preventing short circuit of the test structure is formed on the wafer.

[0052] In step 20, the wafer is subjected to water dicing to obtain the protection ring for preventing short circuit of the test structure.

[0053] In step 30, a ceramic base is provided, the ceramic base has a placement area and ceramic base pins, the protective ring for preventing short circuit of the test structure is placed on the placement area, and the prevention ring of the test structure is placed on the placement area. A shorted guard ring with a guarded test structure. In this embodiment, in fact, when the ceramic base can put down the protective ring for preventing the short circuit of the test structure, the larger the cut of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com