Speed-control switch with kick device

A speed-regulating switch and jumping technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of shortening the service life of switches, prone to twisting and shifting, and spring damage, so as to avoid arc burning of contacts, To avoid the effect of switch lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

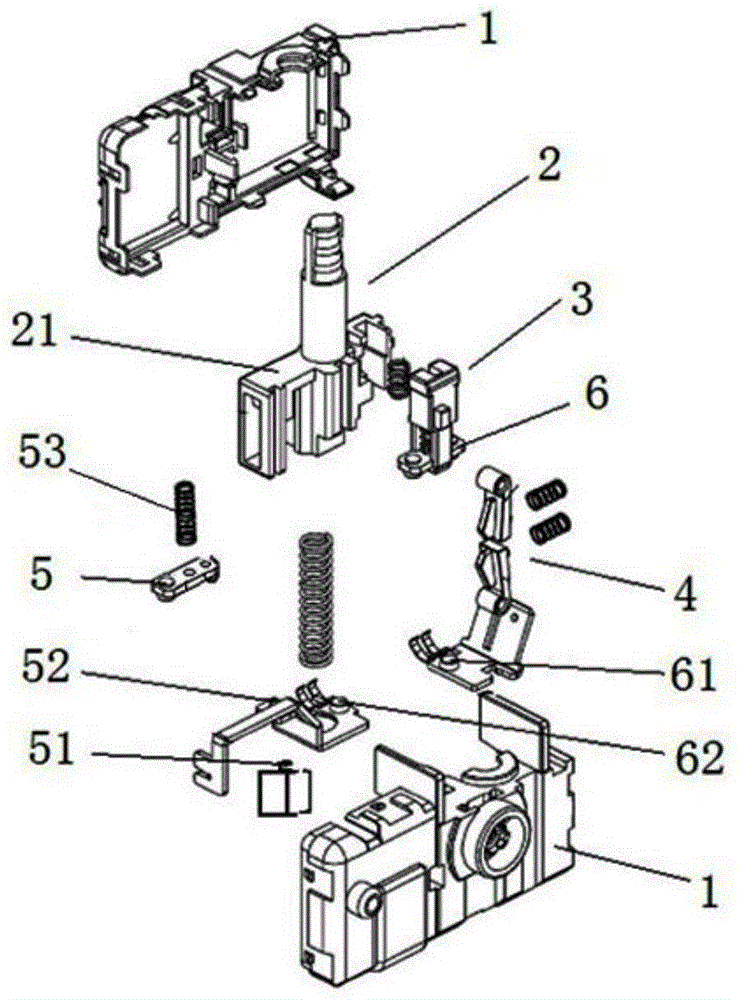

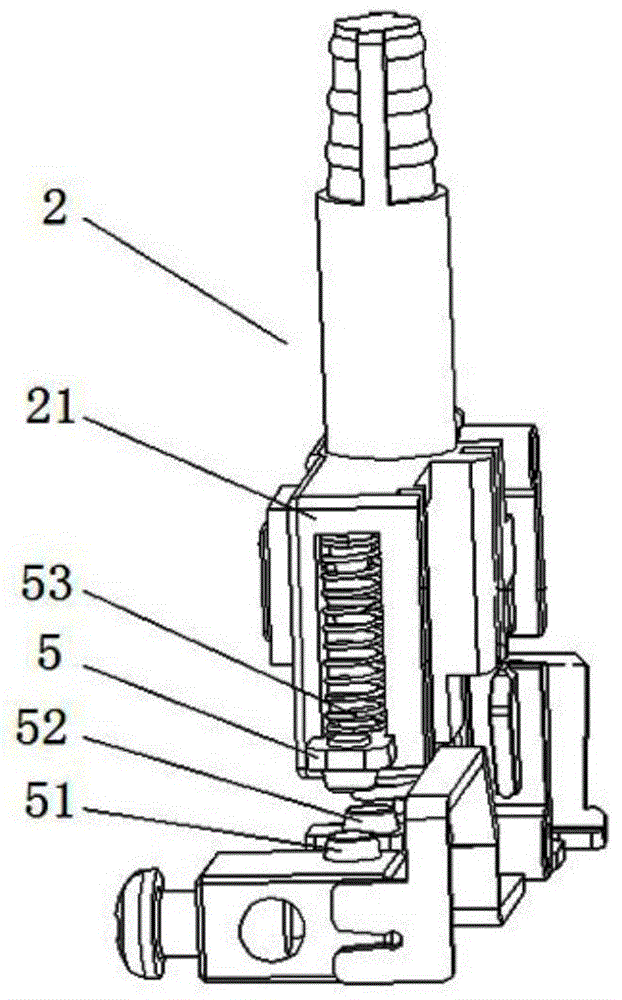

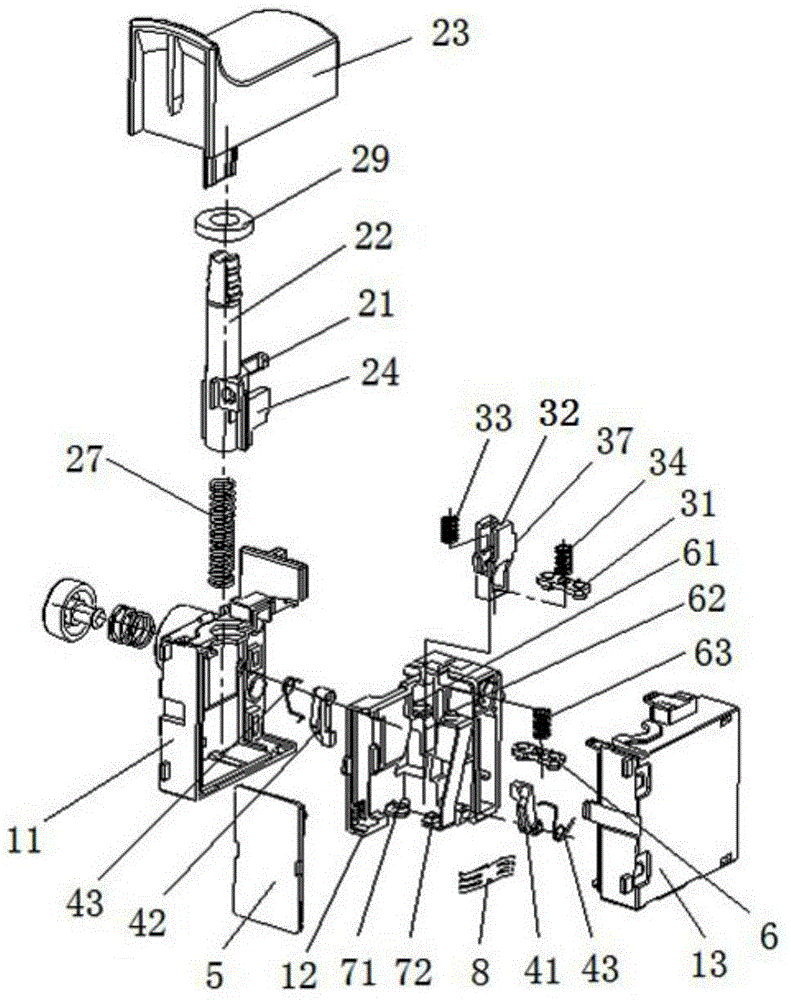

[0048] see image 3 , 10 , 11. The speed regulating switch with a kick device disclosed in the present invention includes a housing 1; and a button assembly 2 arranged inside the housing 1, a contact assembly driven by the button assembly 2, and a Cooperating with the button assembly 2, the second moving contact assembly 3 jumps up and down the locking block assembly 4. Wherein, the button assembly 2 is slidably arranged relative to the housing 1; the contact assembly includes a first contact assembly for controlling the on-off of the speed-regulating circuit board 5, and a first contact assembly for short-circuiting the speed-regulating circuit board. 5 to output the second contact assembly 3 of full voltage to the outside; the second contact assembly 3 includes the second moving contact assembly 3 driven by the button assembly 2 and the second static contact fixed relative to the housing 1 71, 72; the first contact assembly includes the first moving contact 6 driven by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com