Method for detecting disconnection fault point position of high-speed railway comprehensive through ground wire

A technology that penetrates ground wires and disconnection faults, and is applied in the direction of the fault location, which can solve problems such as time-consuming, large amount of engineering, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0034] A kind of embodiment of the inventive method is as follows:

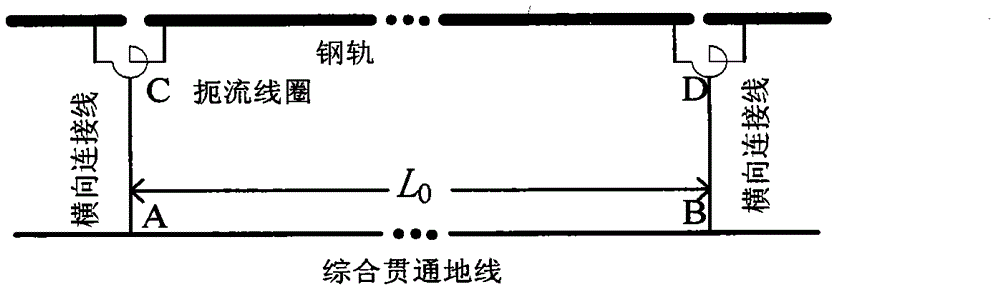

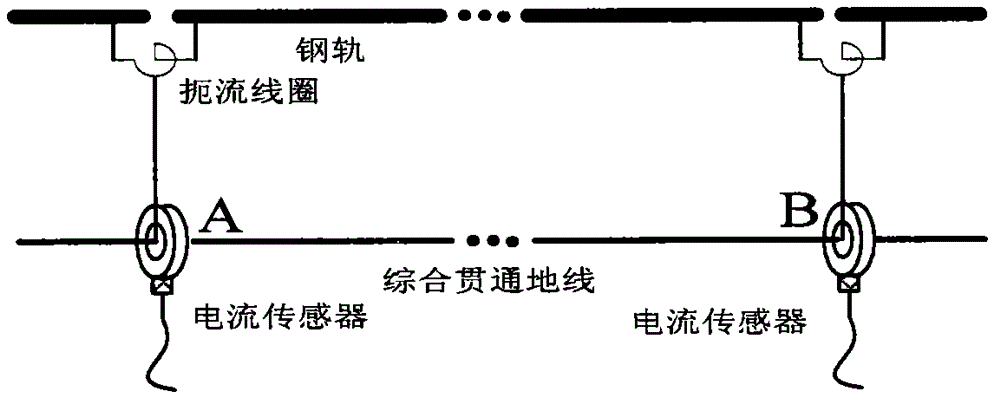

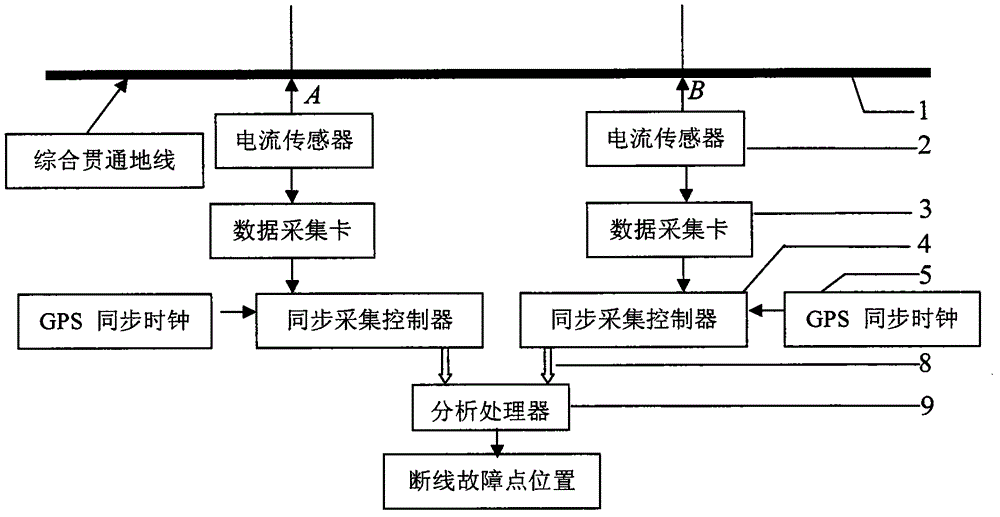

[0035] Step 1: Select a section with a uniform geological structure on the high-speed railway line, and find two adjacent horizontal connecting lines connecting the comprehensive through-ground line 1 and the rail choke coil on this section. Set the current sensor 2 at the connecting points A and B connected by the horizontal connecting line, and record the distance L between the two connecting points (two measuring points) 0 .

[0036] Step 2: When the integrated through-ground wire is in good condition, no disconnection occurs, and the train passes on the rail near the measurement point, the signals of each current sensor are collected synchronously, and the sensor closest to the train is set as the first sensor, and Use this measurement point as a reference point, and set the sensor farther from the train as the second sensor. When a broken line fault occurs in the integrated ground wire and the train pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com