A double-tower double-circulation desulfurization system and method that cancels the accident slurry system

A desulfurization system and double-cycle technology, applied in the field of desulfurization, can solve the problems of high one-time cost and high operation and maintenance cost, and achieve the effect of reducing maintenance workload, maintenance engineering workload and construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

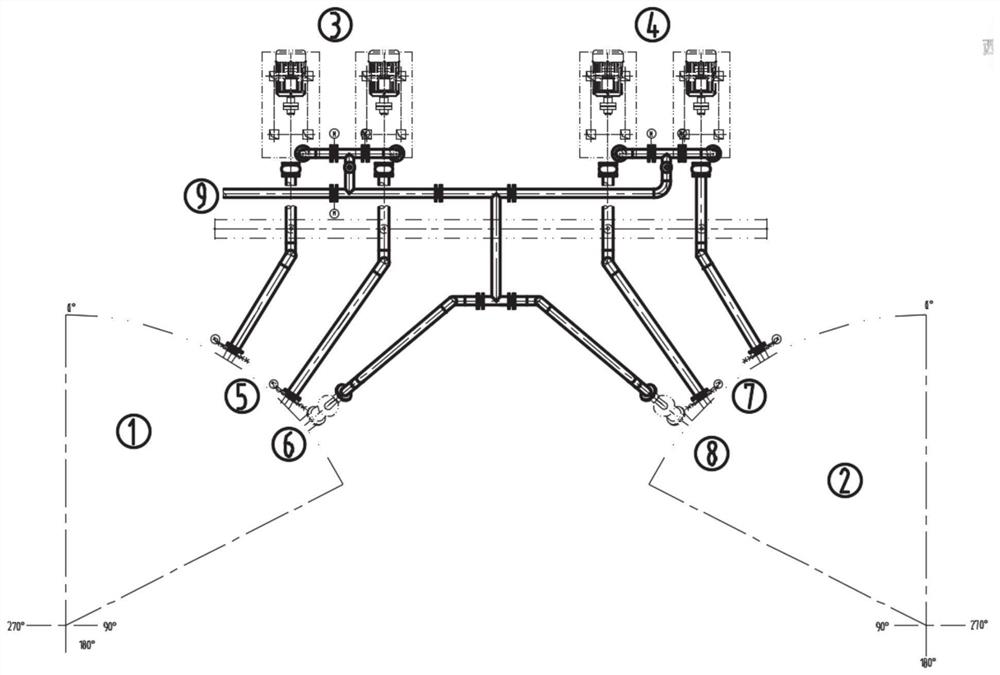

[0021] Such as figure 1 As shown, a double-tower double-cycle desulfurization system that cancels the accident slurry system includes a primary absorption tower and a secondary absorption tower. The primary absorption tower is connected to the gypsum discharge pump of the primary tower through the first pipeline, and the secondary absorption tower passes through The second pipeline is connected to the secondary gypsum discharge pump; the primary tower gypsum discharge pump and the secondary gypsum discharge pump are both connected to the desulfurization system through the third pipeline; the third pipeline is provided with a return pipeline, and the return pipeline is respectively connected to the primary absorption tower It is connected with the secondary absorption tower.

[0022] Further, the return pipeline is connected to the primary absorption tower through the gypsum slurry returning pipeline to the primary tower, and the return pipeline is connected to the secondary ab...

Embodiment 2

[0033] The present disclosure also provides a method for using a double-tower double-cycle desulfurization system that cancels the accident slurry system, including:

[0034]When the dual-tower dual-circulation system is in normal operation, the first-stage tower gypsum discharge pump is turned on to discharge the fully oxidized gypsum slurry to the gypsum dehydration system, and the second-stage tower gypsum discharge pump is turned on to discharge the second-stage tower gypsum slurry to the first-stage tower or Gypsum dehydration system;

[0035] When the primary absorption tower is in the maintenance state, the gypsum slurry in the primary absorption tower is discharged to the secondary absorption tower through the gypsum discharge pump of the primary absorption tower and the switching valve and pipeline at the outlet, and the primary absorption tower is restored after the failure is repaired. After operation, the gypsum slurry is sent back to the primary absorption tower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com