Preparation method of gas sensitive sensor based on carbon nano tube-polypyrrole complex network structure

A gas sensor and carbon nanotube technology, applied in the field of nanosensors, can solve problems such as no research reports, and achieve a good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

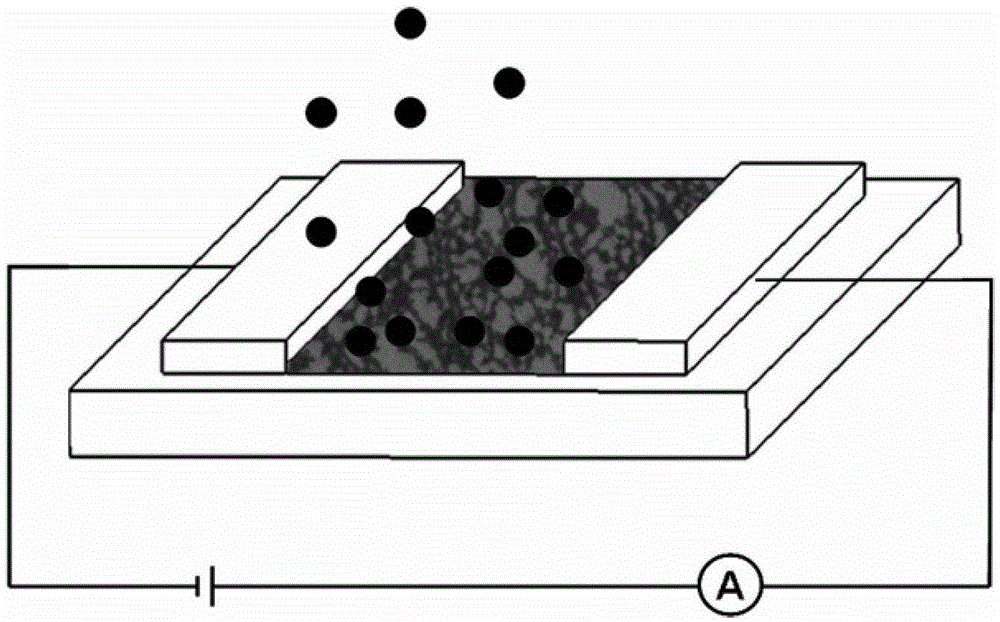

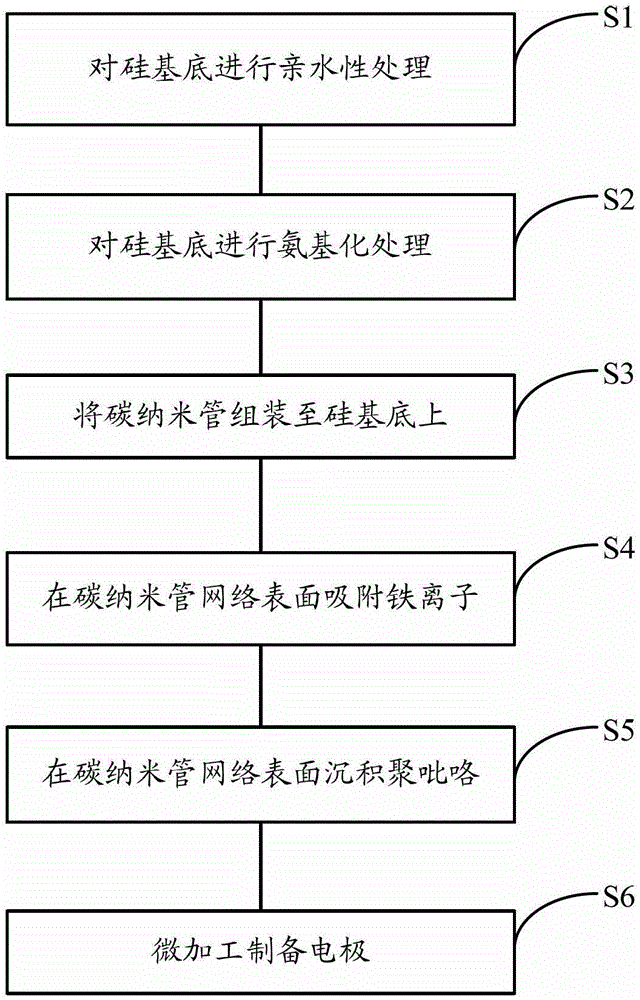

[0044] ginseng figure 1 As shown, the present invention is based on the structural schematic diagram of the carbon nanotube-polypyrrole composite network structure gas sensor. The gas sensor can realize the response to DMMP molecules by detecting the resistance change when the composite network interacts with ammonia molecules. ginseng figure 2 Shown, the preparation method of this gas sensor comprises:

[0045] S1, performing hydrophilic treatment on the silicon substrate;

[0046] S2, performing amination treatment on the silicon substrate;

[0047] S3. Assembling the carbon nanotubes on the silicon substrate;

[0048] S4, adsorbing iron ions on the surface of the carbon nanotube network;

[0049] S5, depositing polypyrrole on the surface of the carbon nanotube network;

[0050] S6. Electrodes are prepared by micromachining.

[0051] The preparation method is specifically:

[0052] S1. Performing hydrophilic treatment on the silicon substrate. The silicon substrate is...

Embodiment 1

[0076] The preparation method described in this embodiment comprises the following steps:

[0077] 1. Put the silicon substrate in 40mL of a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio: 3:1), treat at 80°C for 5 hours, take it out and wash it 4 times, and dry it with high-purity nitrogen to obtain a hydrophilic silicon substrate.

[0078] 2. Soak the hydrophilically treated silicon substrate in an aqueous solution of 2% 3-aminopropyltriethoxysilane for 12 hours, take it out and rinse it with water for 3 times, and dry it with high-purity nitrogen to realize silicon wafer Amination.

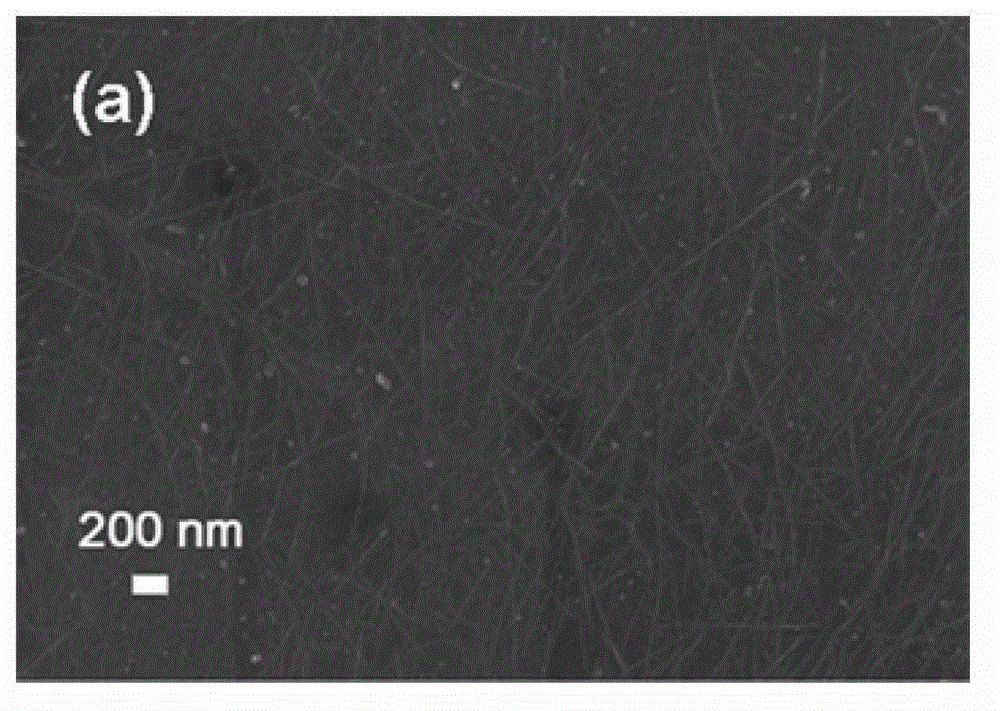

[0079] 3. Sonicate the carboxylated single-walled carbon nanotubes in water for 1 hour, and control the concentration to 1 mg / mL. After centrifugation at 12,000 g, place the aminated silicon substrate in the carboxylated single-walled carbon nanotubes aqueous solution and soak for 20 hours. , washed with deionized water three times, dried with nitrogen, and he...

Embodiment 2

[0084] The procedure is the same as that in Example 1, and the hydrophilic treatment time of the silicon wafer is changed from 5 hours to 1 hour, and the resistance of the prepared device is changed from 800Ω to 1500Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com