Polymer piezoelectric gas sensor system for detecting gases

A gas sensor and gas detection technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of increased difficulty, low sensitivity, low integration, etc., and achieve the effects of wide application, simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

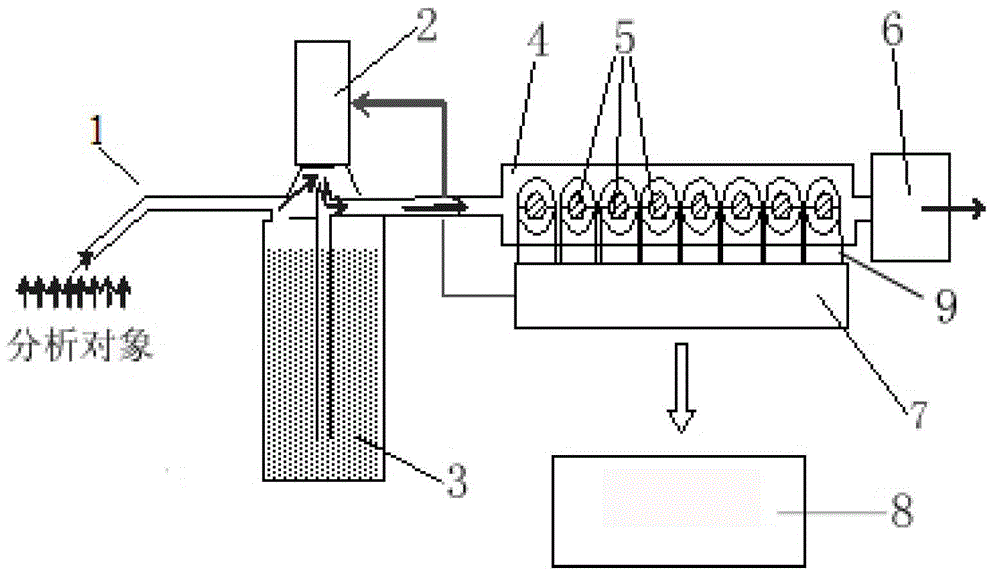

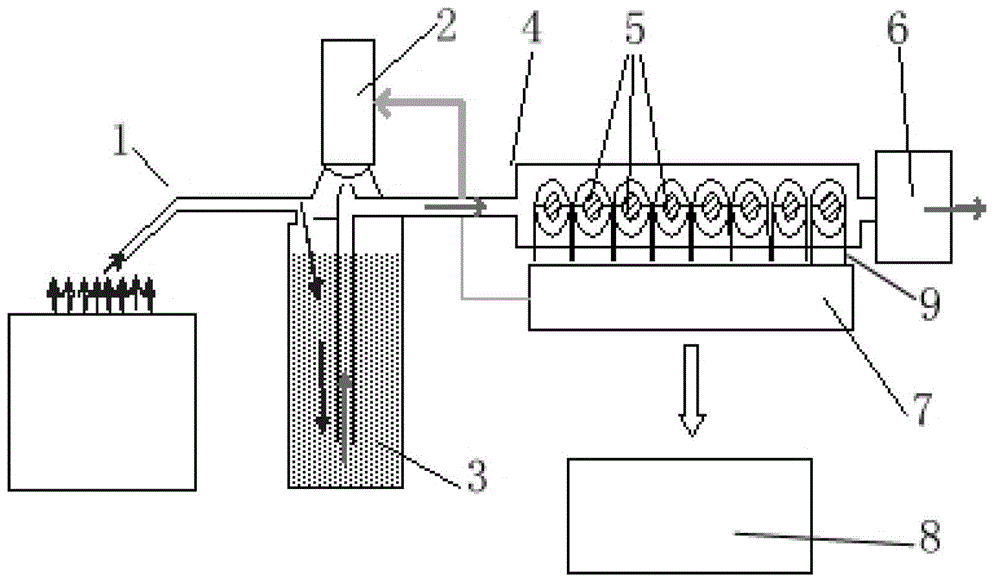

[0017] Describe technical scheme of the present invention in detail below in conjunction with accompanying drawing:

[0018] Such as figure 1 , 2 , are schematic diagrams of the working and cleaning process of the polymer piezoelectric gas sensor system of the present invention, including a gas conduit 1, a solenoid valve 2, a filter 3, a constant temperature chamber 4, a gas sensor array 5, a micro compressor 6, and a frequency meter 7. Control computer 8, wherein the gas conduit 1 is connected with the solenoid valve 2, the thermostatic chamber 4, and the micro compressor 6 in sequence, the solenoid valve 2 is connected with a filter 3, and the sensor array 5 is arranged in the thermostatic chamber 4 , the sensor array 5 is connected to the frequency meter 7 through a wire 9, and the frequency meter 7 is connected to a control computer 8.

[0019] The sensor array consists of 8 gas sensors coated with different polymer films.

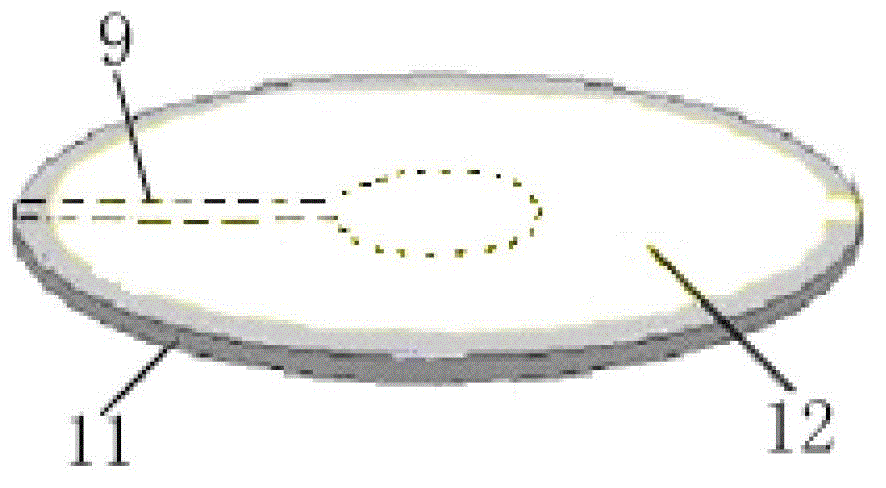

[0020] Such as image 3 , 4 , the gas sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com