Fully-flexible three-dimensional force tactile sensor

A tactile sensor and tactile sensing technology, applied in the field of sensing, can solve the problems of unreliable stability and sensitivity, difficult sensor manufacturing process, etc., and achieve the effect of compact structure, good adaptability and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

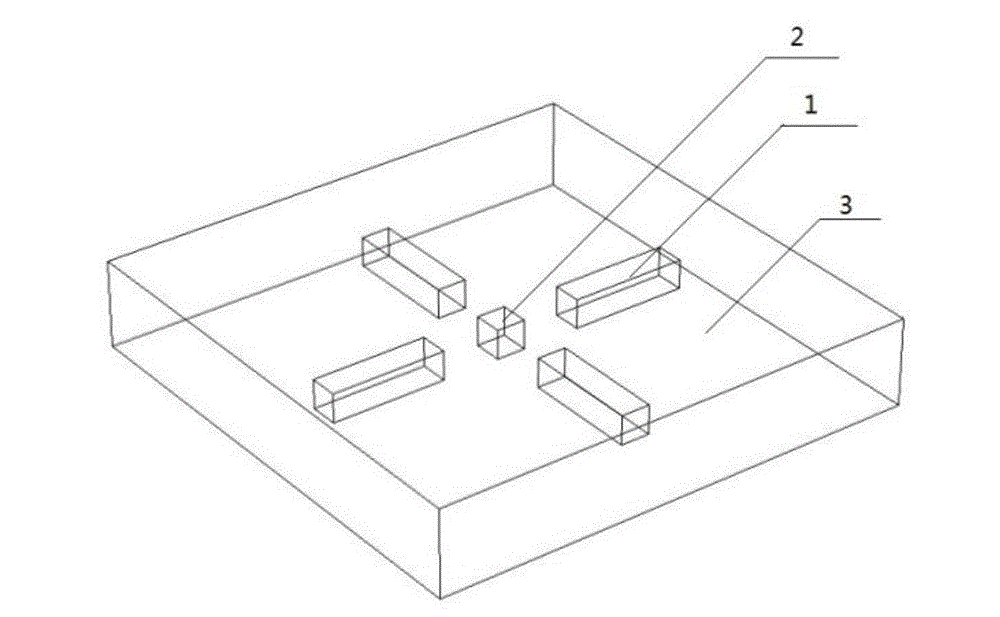

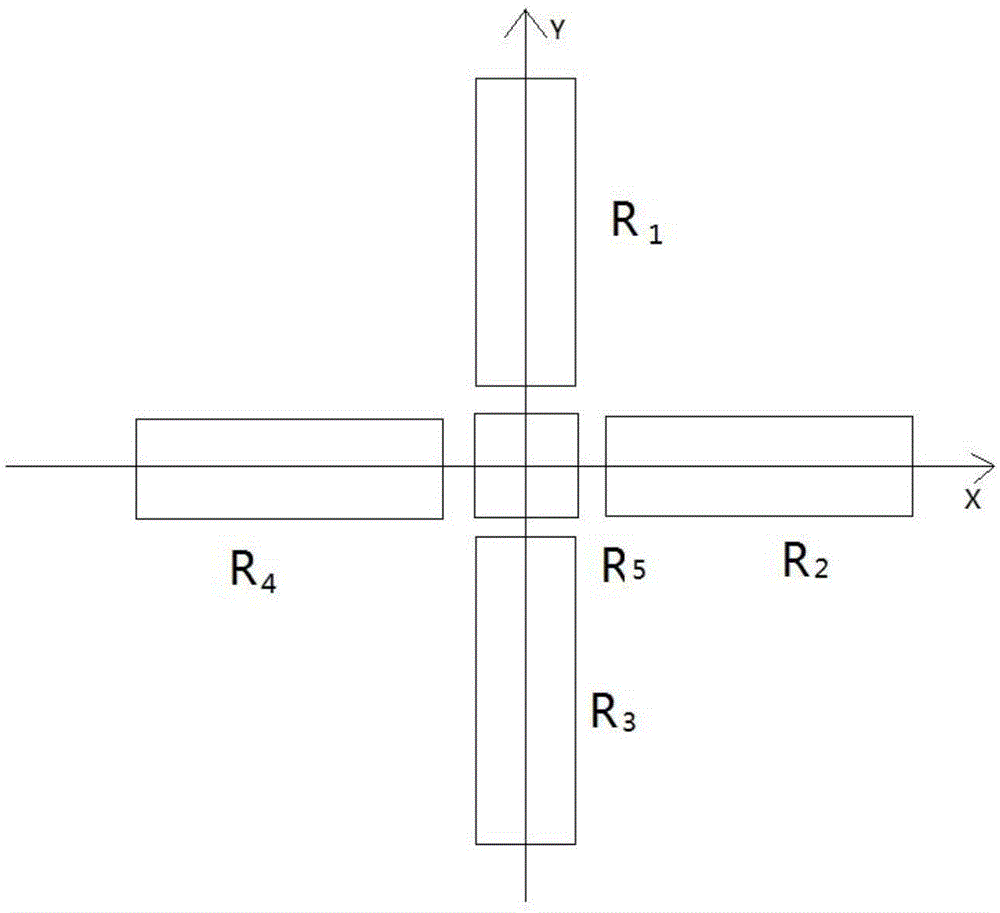

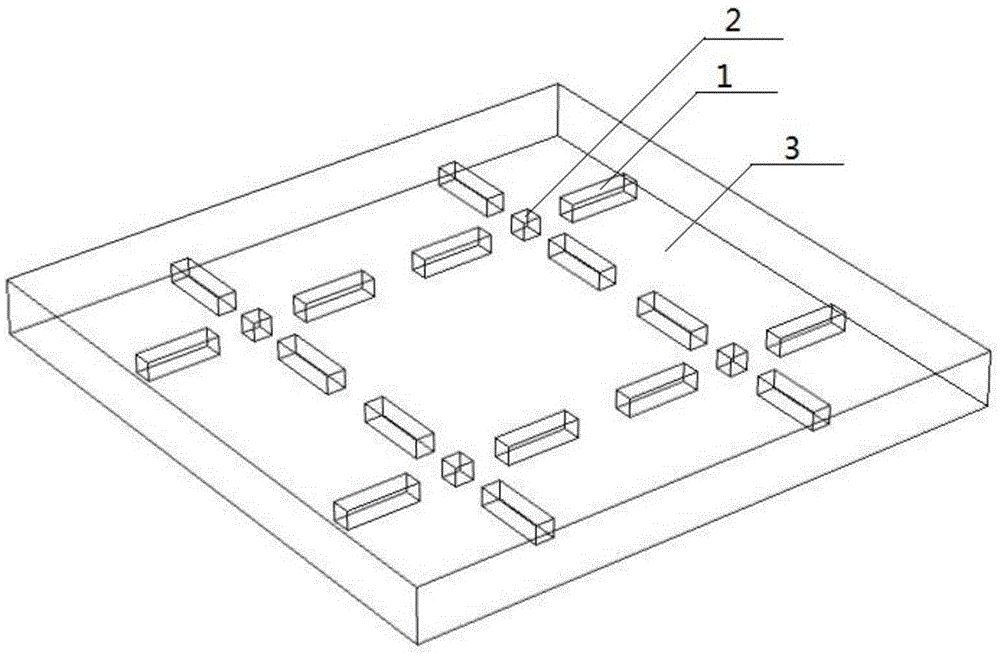

[0028] see figure 1 , figure 2 and image 3 , the structural form of the fully flexible three-dimensional force tactile sensor in this embodiment is: in the flexible matrix, on the same plane, a resistance R5 is formed with a pressure sensitive element as the center; four identical stretch sensitive elements are respectively arranged in The positive direction of the Y axis, the negative direction of the Y axis, the positive direction of the X axis, and the positive direction of the X axis form the resistance R 1 , resistance R 3 , resistance R 2 and resistor R 4 , forming a three-dimensional force tactile sensing unit arranged on the surface of the detected area; each three-dimensional force tactile sensing unit is arranged in an array on the surface of the detected area, and filled with flexible substrates to form a three-dimensional force tactile sensor.

[0029] The structural form of the fully flexible three-dimensional force tactile sensor in this embodiment is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com