Grid section pin for sintering pallet

A technology for vehicles and grate bars is applied in the field of grate bars and pins for sintering machine trolleys. , Solve the problem of air leakage and improve the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

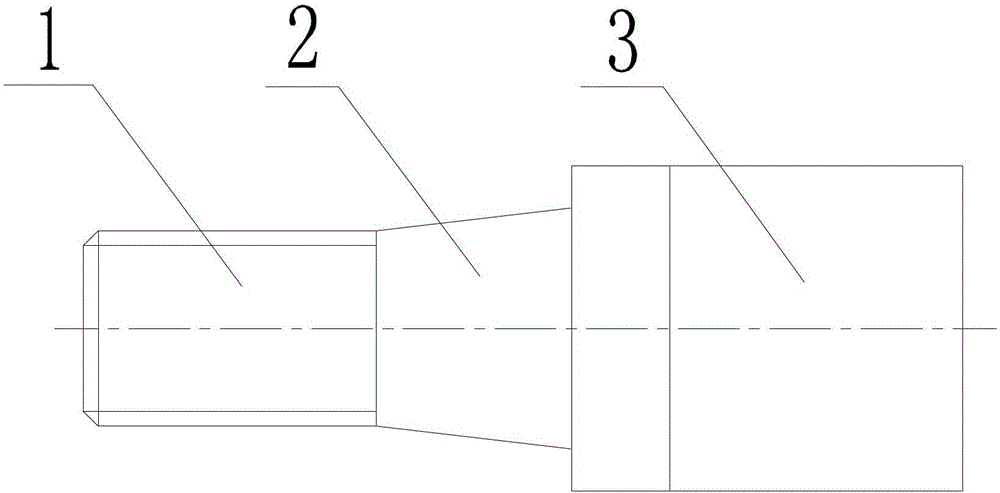

[0013] A grate bar pin for a sintering machine trolley provided in this embodiment has a structure such as figure 1 As shown, it includes a cylindrical pin body 1, a truncated conical pin body 2 and a square briquetting block 3; Link to each other, the diameter of the upper bottom surface of the compression pin body 2 is equal to the diameter of the pin body 1 and less than the diameter of the lower bottom surface of the compression pin body 2, and the diameter of the lower bottom surface of the compression pin body 2 is less than the side length of the bottom surface of the briquetting block 3; the pin body 1, The axes of the briquetting block 3 and the compression pin body 2 are on the same straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com