Slope hoisting and crushing system for deep open-pit mine

A crushing system and open-pit mine technology, which is applied in open-pit mining, special mining, earth drilling and mining, etc., can solve the problems of wasteful construction costs of equipment, inflexible movement of slope track extension, etc., so as to save construction costs, Low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

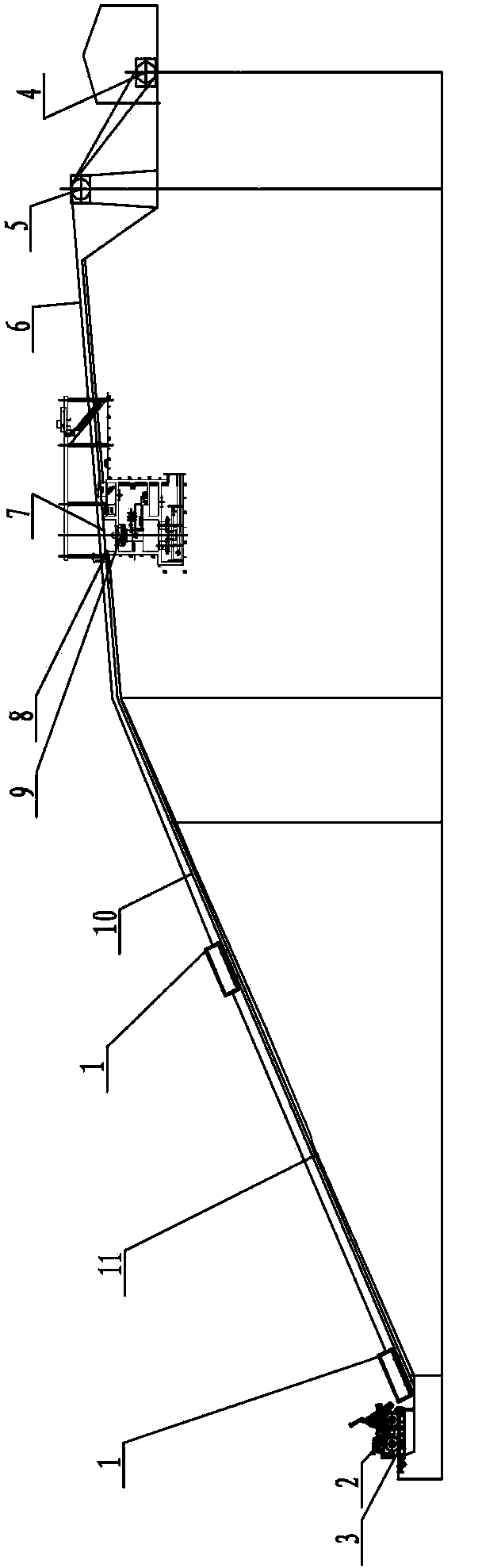

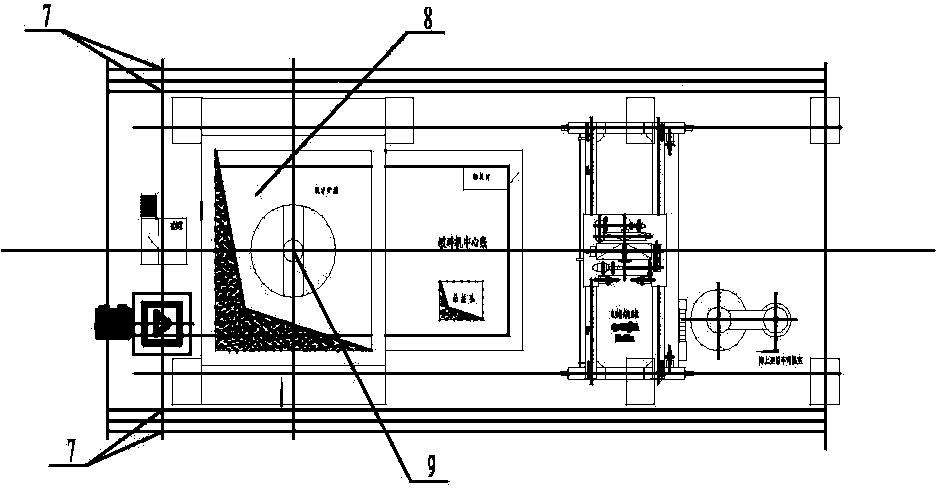

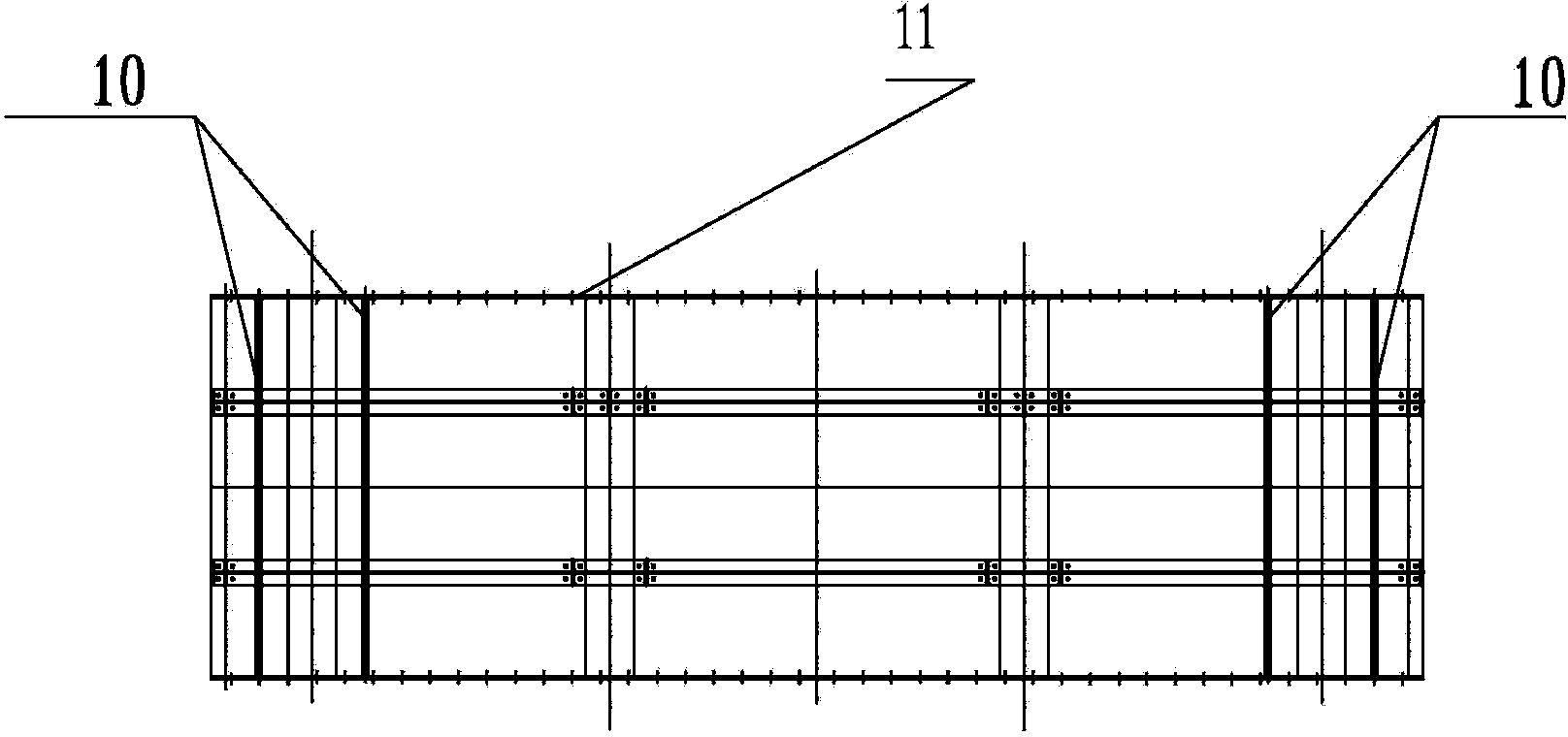

[0018] Such as figure 1 , 2 As shown, a kind of deep concave open-pit mine slope lifting and crushing system of the present invention comprises a track 10 laid on the top of the deep concave open-pit stope and on the slope, and a hoist 4 arranged on the top of the deep concave open-pit stope. The steel structure box girder 11 is installed in combination on the slope of the open pit, and the track 10 on the slope is laid on the steel structure box girder 11 (see image 3 , 4 ), with the extension of the bottom of the open pit, the independent slope steel structure box girder 11 does not have a concrete foundation, it is flexible and convenient to change and move the position in the open pit, saving investment, ensuring the production capacity of the deep concave open pit, reducing Transportation costs. A mine car 1 is arranged on the track 10; the hoist 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com