Bridge type precast reinforced concrete hidden beam slab pavement system and construction method thereof

A technology of reinforced concrete and concealed beams, applied to roads, roads, special pavements, etc., can solve problems such as easy generation of large amounts of construction waste, long construction period, and difficult repairs, so as to achieve high construction efficiency, reduce project cost and other costs, and save The effect of material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

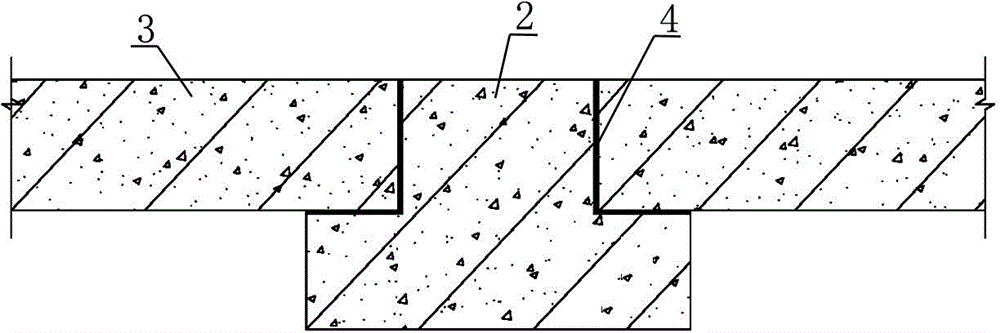

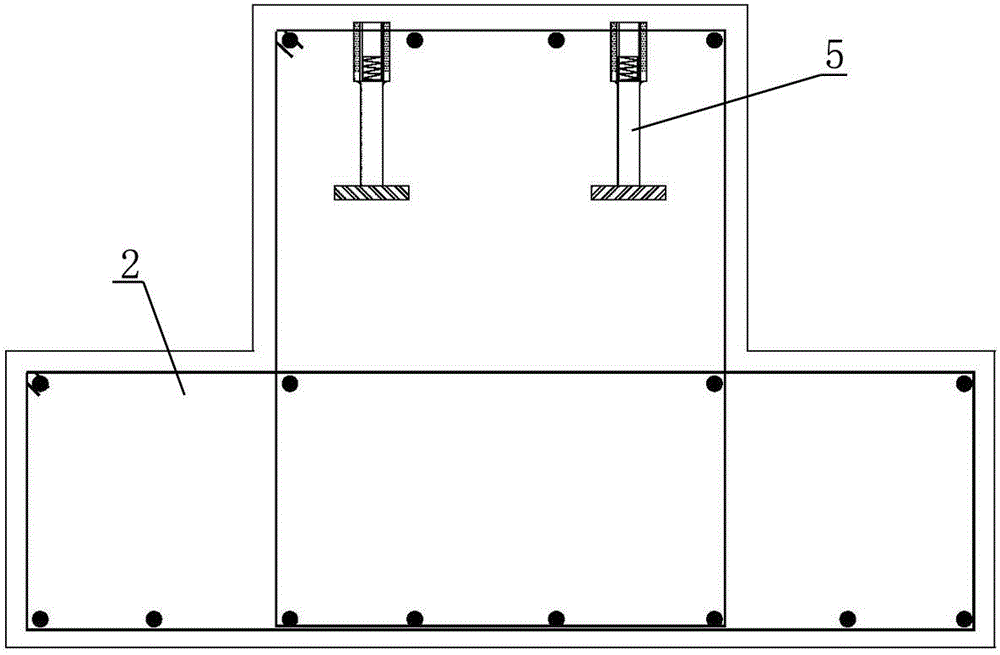

[0041] Examples see Figures 1 to 4 as well as Figure 6 As shown, a bridge-type prefabricated reinforced concrete concealed beam slab pavement system includes a foundation and a road slab, the foundation is a prefabricated inverted T-shaped strip foundation 2, and the road slab is a prefabricated reinforced concrete concealed beam slab 3. The upper surfaces of the prefabricated inverted T-shaped strip foundation 2 and the prefabricated reinforced concrete hidden beam slab 3 are pre-embedded with four wire pipes 5; the top surface of the wire pipes 5 is welded to the upper steel bar 3.1 The prefabricated reinforced concrete concealed beam slab 3 is mounted on the steps on the side of the prefabricated inverted T-shaped strip foundation 2, and an L-shaped rubber pad 4 is placed on the contact surface between the two.

[0042] see Figure 8 and Figure 9 , the wire pipe 5 is composed of an internally threaded casing 5.1, an externally threaded steel rod 5.2, a rectangular anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com