Antibacterial treatment method for natural silk fabric surface

A technology of natural silk and treatment method, which is applied in fiber treatment, animal fiber, textiles and paper making, etc. It can solve the problems of easy adhesion, economic loss, stains, etc., and achieve a uniform antibacterial layer on the surface, easy to popularize and apply, and good grafting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Implement the antibacterial treatment method on the surface of a kind of natural silk fabric provided by the present invention, this antibacterial treatment method is to carry out according to the following steps:

[0022] Step 1, according to silicon dioxide (SiO 2 ) ﹕ Silver nitrate (AgNO 3 ) ﹕ Deionized water (H 2 O) = 200:1 ~ 15:2000 was mixed under magnetic stirring for 20 min, glucose (C 6 h 12 o 6 ): Sodium hydroxide (NaOH): Deionized water (H 2 O) = 2 ~ 30: 1 ~ 5: 3000 composition is added to the above mixed solution, and reacted in vacuum at 50 ~ 70 ℃ for 10 ~ 30 min. The reaction principle is:

[0023] Ag + +OH - →AgOH↓

[0024] 2AgOH →Ag 2 O+H 2 o

[0025] C 5 h 6 (OH) 5 CHO+Ag 2 O+OH - →C 5 h 6 (OH) 5 COO - +2Ag↓+H 2 o

[0026] Filter through a vacuum filter, wash with deionized water, and dry in a constant temperature oven at 50°C to obtain a composite antibacterial agent.

[0027] Among them, the reaction under vacuum conditions i...

Embodiment 1

[0036] 0.12 g AgNO 3 Dissolved in 20 ml deionized water to make a solution, 2 g SiO 2 In the above solution, soak at room temperature for 20 min, so that the silver ions are fully and uniformly adsorbed on the SiO 2 In the void; press C 6 h 12 o 6 Prepare a solution with 0.3 g, 0.048 g of NaOH, and 30 ml of deionized water, slowly add the prepared solution into the above cloudy liquid, react at 50 °C for 10 min under vacuum conditions, perform suction filtration, washing, and drying , to obtain a light-colored silica silver-loaded composite antibacterial agent.

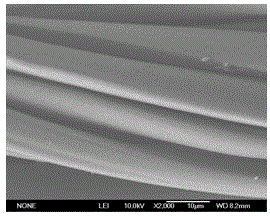

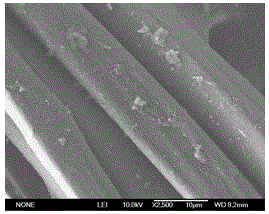

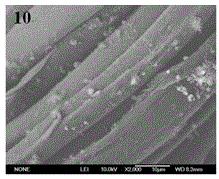

[0037] Add 0.5 g compound antibacterial agent and 0.5 ml coupling agent into 40 ml deionized water, mix evenly, and react at 70 °C for 30 min to prepare antibacterial functional mother liquid; cool the antibacterial functional liquid to 40 °C, add washed and dried 0.7 g of natural silk fabric was reacted at 40 °C for 2 h, washed and dried to obtain long-acting antibacterial silk fabric, and the color and gloss...

Embodiment 2

[0039] 0.06 g AgNO 3 Dissolved in 20 ml deionized water to make a solution, 2 g SiO 2 In the above solution, soak at room temperature for 20 min, so that the silver ions are fully and uniformly adsorbed on the SiO 2 In the void; press C 6 h 12 o 6 Prepare a solution with 0.14 g, 0.024 g of NaOH, and 30 ml of deionized water, slowly add the prepared solution to the above cloudy liquid, react at 60 °C for 10 min under vacuum conditions, perform suction filtration, washing, and drying , to obtain a light-colored silica silver-loaded composite antibacterial agent.

[0040] Add 1 g of compound antibacterial agent and 1 ml of coupling agent into 40 ml of deionized water, mix evenly, and react at 70 °C for 30 min to prepare antibacterial functional mother liquid; cool the antibacterial functional liquid to 40 °C, add washed and dried 0.7 g of natural silk fabric was reacted at 40 °C for 2 h, washed and dried to obtain long-acting antibacterial silk fabric, and the color and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com