A kind of method of chlorine dioxide bleaching cotton fabric

A chlorine dioxide and cotton fabric technology, applied in bleaching products, textiles and papermaking, etc., can solve the problems of low utilization rate of chlorine dioxide, unfavorable control of bleaching production, prolonged bleaching time, etc., so as to shorten the process operation time and shorten the Bleaching time, the effect of improving the bleaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

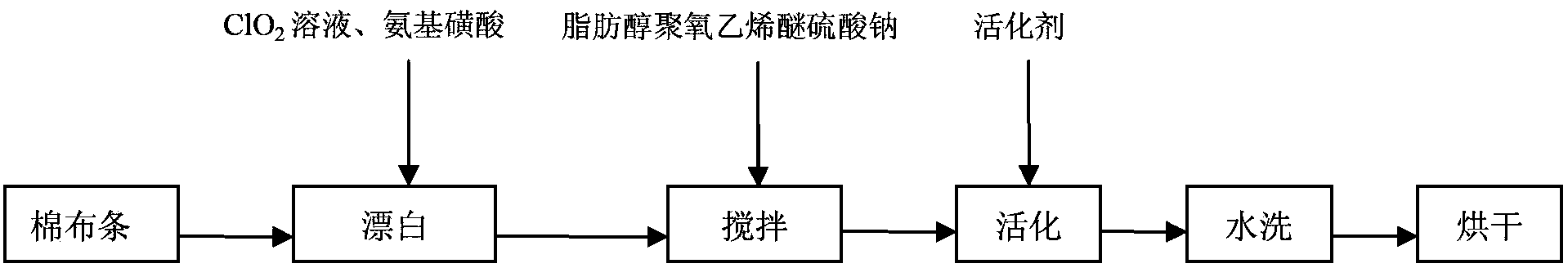

Method used

Image

Examples

Embodiment 1

[0024] To 100mL mass concentration is 0.2%ClO 2 Add 2 mL of sulfamic acid solution with a mass concentration of 8% into the solution, and stir evenly. Throw in 5 g of cotton strips to fully submerge. Then add 0.1 g of fatty alcohol polyoxyethylene ether sodium sulfate, control the bleaching temperature at 35°C, maintain the pH value of the bleaching system at 3-4, and stir for about 2 minutes every 30 minutes. After 120 min of treatment, 4 mL of 2 mol / L hydrochloric acid was added to the solution, and stirred evenly. End the experiment after standing for 30 minutes, take out the cloth sample, wash it with 150mL water for 3 times, and put it in an oven at 120°C for 3 hours.

Embodiment 2

[0026] To 100mL mass concentration is 0.3%ClO 2 Add 2 mL of sulfamic acid solution with a mass concentration of 9% into the solution, and stir evenly. Throw in 5 g of cotton strips to fully submerge. Then add 0.15 g of fatty alcohol polyoxyethylene ether sodium sulfate, control the bleaching temperature at 40°C, maintain the pH value of the bleaching system at 3-4, and stir for about 2 minutes every 30 minutes. After 140 min of treatment, add 4 mL of 2 mol / L acetic acid to the solution and stir well. End the experiment after standing for 30 minutes, take out the cloth sample, wash it with 150mL water for 3 times, and put it in an oven at 120°C for 4 hours.

Embodiment 3

[0028] To 100mL mass concentration is 0.5%ClO 2 Add 2 mL of sulfamic acid solution with a mass concentration of 10% into the solution, and stir evenly. Throw in 5 g of cotton strips to fully submerge. Then add 0.2 g of fatty alcohol polyoxyethylene ether sodium sulfate, control the bleaching temperature at 45°C, maintain the pH value of the bleaching system at 3-4, and stir for about 2 minutes every 30 minutes. After 150 min of treatment, 4 mL of 2 mol / L citric acid was added to the solution and stirred evenly. End the experiment after standing for 30 minutes, take out the cloth sample, wash it with 150mL of water three times, and put it in an oven at 120°C for 3.5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com