Disc-type microwave continuous splitting device and method for splitting waste rubber

A technology of cracking device and waste rubber, which is applied in the preparation of liquid hydrocarbon mixture, plastic recycling, fibrous filler, etc., can solve the problems of low processing efficiency of microwave cracking device, the cracking effect needs to be improved, and the process control is difficult. Cracking efficiency, optimized cracking effect, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

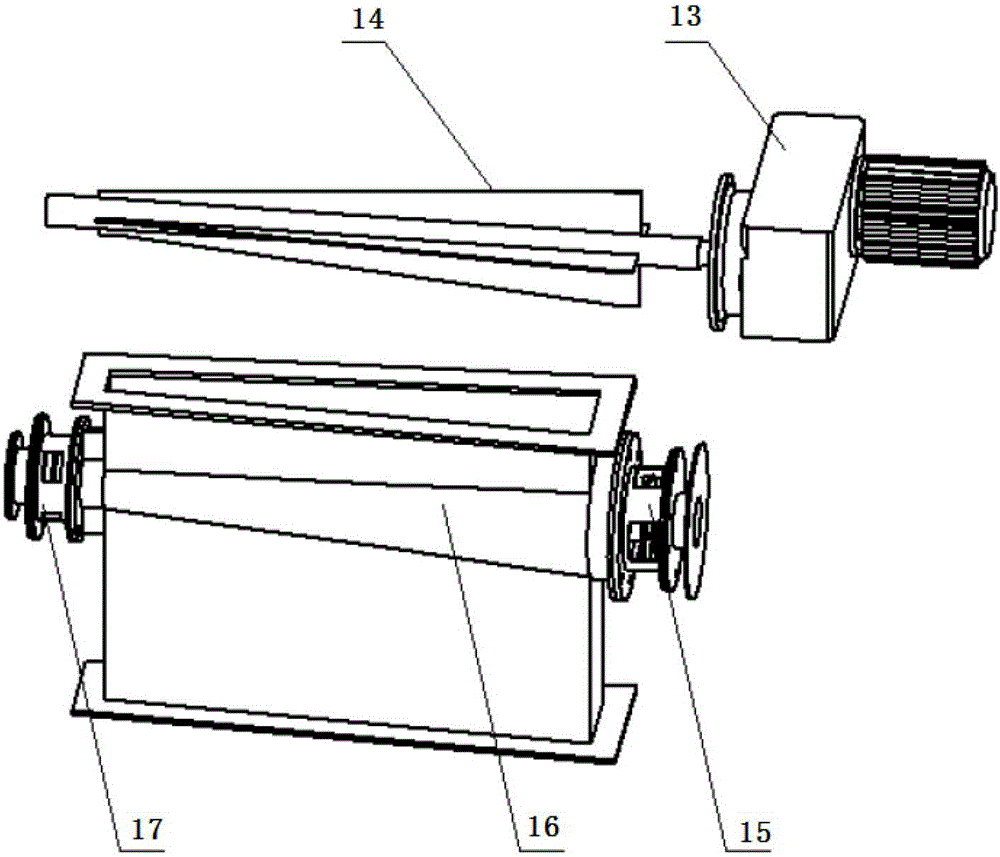

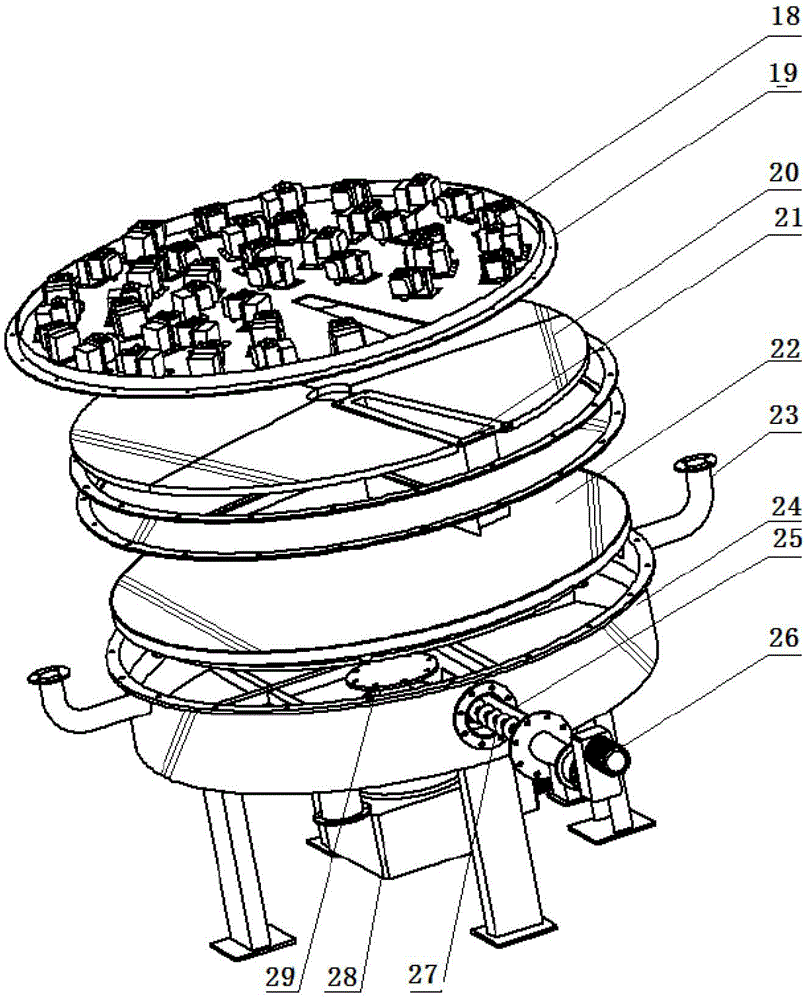

[0027] As shown in the accompanying drawings, the present invention includes a disc-type microwave continuous cracking device, including a feeding assembly, a microwave cracking assembly, a discharge assembly and a control assembly, which are connected in sequence. The microwave cracking assembly includes a microwave generator 18, a microwave Metal sealing plate 20, cracking cavity 24, rotating disc 22, disc drive motor 28, non-metallic sealing plate 20 separates cracking cavity 24 into upper and lower two parts, rotating disc 22 is at the bottom of cracking cavity 24, and The disk drive motor 28 is driven to rotate through a drive shaft 29, and the microwave generator 18 is arranged on the circular flange 19 above the cracking chamber.

[0028] The feeding component includes a storage tank 3, a rotary feeding valve 8, and the discharging component includes a pyrolysis oil and gas outlet connecting pipe 6, a solid cracking product exporter 9, a solid cracking product receiving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com