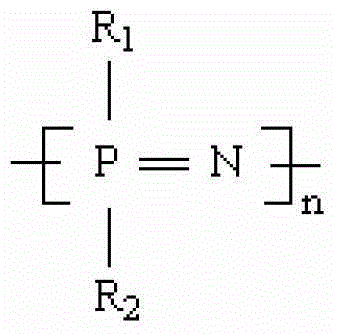

Method for purifying aryloxy polyphosphazene

A technology of aryloxy polyphosphazene and purification method, which is applied in the field of purification of aryloxy polyphosphazene and aryloxy polyphosphazene, and can solve problems such as high content of "impurities", inability to vulcanize at high temperature, and easy degradation , to achieve the effect of low cost, satisfying industrial application, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1, respectively weigh chemically pure absolute ethanol and acetone according to the ratio of 20 / 80 by weight, and mix them fully in a clean container to obtain a mixed solvent;

[0024] Step 2: Set the temperature of the kneading chamber of the kneader to 40°C. After constant temperature, weigh about 1 / 2 of the volume of the kneader and knead the aryloxypolyphosphazene in the kneader, and use a pipette to inject about 1 / 2 of the volume of the kneader. 1 / 3 of deionized water, kneading for 5 minutes, remove the upper aqueous solution, use a pipette to remove the aqueous solution above the aryloxy polyphosphazene in the kneader, then repeat the injection of deionized water, repeat the above process until the pH of the removed aqueous solution is When the value is 7, stop washing;

[0025] Step 3: Inject anhydrous ethanol accounting for about 1 / 2 of the volume of the kneader into the washed aryloxy polyphosphazene and knead for 5 to 7 minutes, and use a pipette to remo...

Embodiment 2

[0033] Step 1, respectively weigh chemically pure absolute ethanol and acetone according to the ratio of 50 / 50 by weight, and mix them fully in a clean container to obtain a mixed solvent;

[0034] Step 2: Set the temperature of the kneading chamber of the kneader to 40°C. After constant temperature, weigh about 1 / 2 of the volume of the kneader and knead the aryloxypolyphosphazene in the kneader, and use a pipette to inject about 1 / 2 of the volume of the kneader. 1 / 2 of deionized water, knead for 5 minutes and then remove the upper aqueous solution, use a pipette to remove the aqueous solution above the aryloxy polyphosphazene in the kneader, then repeat the injection of deionized water, repeat the above process until the pH of the removed aqueous solution is When the value is 7, stop washing;

[0035] Step 3: Inject anhydrous ethanol accounting for about 1 / 3 of the volume of the kneader into the washed aryloxy polyphosphazene and knead for 5-7 minutes, and remove the solution...

Embodiment 3

[0041]Step 1, respectively weigh chemically pure absolute ethanol and acetone according to the ratio of 40 / 60 by weight, and mix them fully in a clean container to obtain a mixed solvent;

[0042] Step 2: Set the temperature of the kneading chamber of the kneader to 40°C. After constant temperature, weigh about 1 / 2 of the volume of the kneader and knead the aryloxypolyphosphazene in the kneader, and use a pipette to inject about 1 / 2 of the volume of the kneader. 2 / 5 deionized water, after kneading for 5 minutes, remove the upper aqueous solution, use a pipette to remove the aqueous solution above the aryloxy polyphosphazene in the kneader, then repeat the injection of deionized water, repeat the above process until the pH of the removed aqueous solution is When the value is 7, stop washing;

[0043] Step 3: Inject anhydrous ethanol accounting for about 1 / 2 of the volume of the kneader into the washed aryloxy polyphosphazene and knead for 5 to 7 minutes, and use a pipette to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com