Preparation method of composite opaque glaze

A technology of compounding milk and glaze powder is applied in the field of building sanitary ceramic decoration, which can solve the problems of scarcity of resources, discoloration of glaze, high viscosity of opaque glaze at high temperature, etc., and achieves simple process, complete glaze and good opacity effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) According to weight percentage, 30% feldspar, 22.5% quartz, 10% wollastonite, 3%-8% zirconium silicate, 15% Suzhou soil, 6% calcined and 2.5% of , after weighing each material, mix and grind evenly, and sieve to obtain glaze powder, the fineness of the glaze powder is less than 2% after passing through the million-hole sieve;

[0014] (2) Mix and grind the glaze powder prepared in step (1) with water and a ball mill in a ratio of 1: (0.9-1): (0.6-0.8) to obtain a composite opacified glaze;

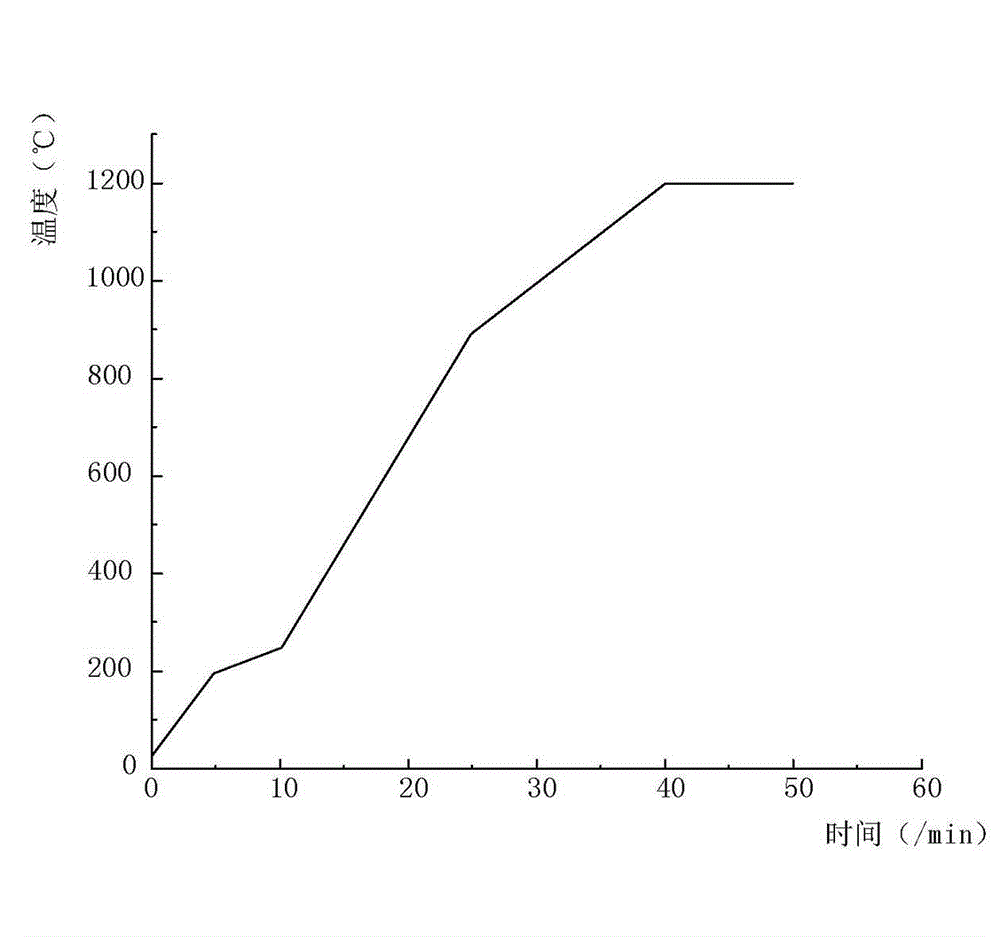

[0015] (3) Glaze the composite opacified glaze on the ceramic body by spraying glaze, the thickness of the glaze is 1mm, after the glazed body is dried, it is fired at 1150°C to 1250°C for 1 hour, and the furnace Ceramic products with high white opacity effect can be obtained after cooling.

[0016] In the above preparation method, the glaze powder, water, and ball mill are used in a ratio of 1: (0.9-1): (0.6-0.8) to make a composite opaque glaze, which is evenly applied on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com