Scooter hub internally provided with drive speed transmission

A speed change device and skateboard technology, which is applied in the direction of wheel transmission, vehicle gearbox, vehicle parts, etc., can solve the problems of chain wear, poor safety and stability, and low service life, and achieve high assembly accuracy, high stability, The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

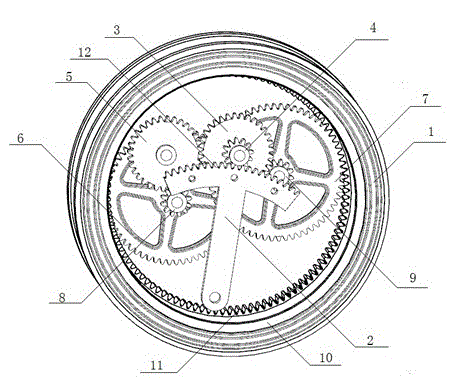

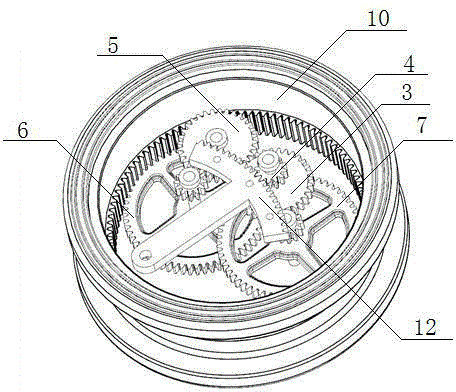

[0024] Such as Figure 1-3 As shown, the present invention is a skateboard wheel hub with a built-in drive transmission device. The hub 1 is hollow and equipped with a drive transmission device. The drive transmission device includes a driving gear 3 and a pair of driven gears. The driven gear is provided with a ratchet. The left side of 3 meshes with the ratchet of the left driven gear 6, the right side of the driving gear 3 meshes with the ratchet of the right driven gear 7 through the intermediate gear 5, the inner circumference of the rim 10 of the hub 1 is provided with teeth 11, and the left driven The gear 6 meshes with the right driven gear 7 and the teeth 11 on the inner circumference of the rim 10 , and the driving gear 3 meshes with the driving handle 2 .

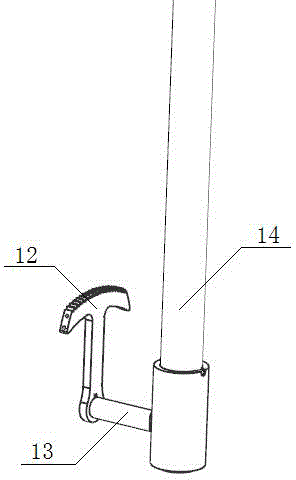

[0025] The driving handle 2 is provided with a shifting tooth swing rod 12, a transverse connecting rod 13 and a hand-held pull rod 14, and the shifting tooth swing rod 12 is connected to the hand-held pull rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com