Making technology of hot-pressed xylary automobile ornament

A technology for auto trim and manufacturing process, applied in the field of auto parts, can solve problems such as cracking and product displacement, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

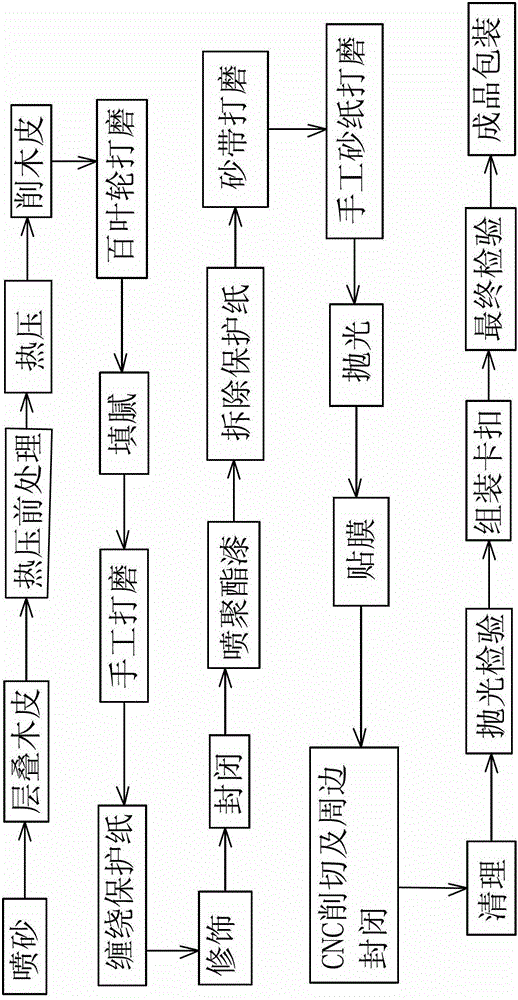

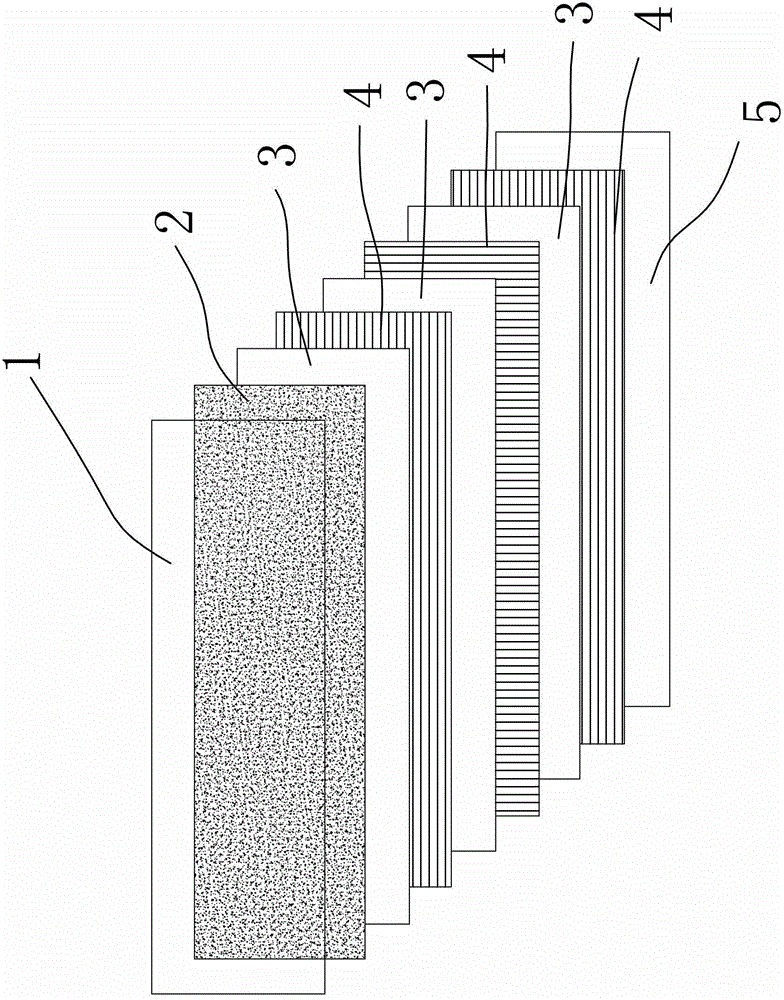

[0030] Such as figure 1 As shown, the manufacturing process of the hot-pressed real wood car trim is to compound the veneer on the base of the car trim, and to produce piano black car trim according to the following steps. Step 1, sandblasting: spray sand on the base production surface, The sand specification is P24 sand; step 2, lamination veneer: the veneer includes nine layers of structure, and stacked according to the order of top and bottom, such as figure 2 As shown, the first layer: plastic sheet 1; here the plastic sheet 1 can protect the veneer from discoloration under high temperature, the second layer: surface veneer 2; here the surface veneer 2 is made of piano black veneer, the third layer: wood glue paper 3 (glue); the fourth layer: poplar 4; here the poplar 4 uses Anlige dyed poplar 4, the fifth layer: wood glue paper 3; the sixth layer: poplar wood 4; the seventh layer: wood glue paper 3 ( Glue); eighth layer: poplar wood 4; ninth layer: aluminum tape 5 (glue...

Embodiment 2

[0032] The difference between this embodiment and Example 1 is the production of black walnut-colored car trims. The black walnut car trims are produced according to the following steps. Step 1, sandblasting: sand grains are sprayed on the substrate production surface, wherein the sand specifications It is P24 sand; step 2, laminated veneer: the veneer includes nine layers of structure, and stacked in order of up and down, wherein the first layer: plastic sheet 1; here plastic sheet 1 can protect the veneer from discoloration under high temperature, the second The second layer: surface veneer 2; here the surface veneer 2 is made of piano black veneer, the third layer: wood glue paper 3 (glue); the fourth layer: poplar wood 4; here poplar wood 4 uses black walnut veneer, the fifth layer: wood Tape 3; Layer 6: Poplar 4; Layer 7: Wood Tape 3 (glue); Layer 8: Poplar 4; Layer 9: Aluminum Tape 5 (glue); Layer 4: Poplar 4 is horizontal arrangement, the sixth layer: poplar 4 is vertic...

Embodiment 3

[0034] The difference between this embodiment and Embodiment 1 is the production of car trims in the color of Anlige, which includes the following steps to produce the car trims of Anlige. Step 1, sandblasting: spray sand grains on the production surface of the substrate, wherein the sand specifications It is P24 sand; step 2, laminated veneer: the veneer includes nine layers of structure, and stacked in order of up and down, wherein the first layer: plastic sheet 1; here plastic sheet 1 can protect the veneer from discoloration under high temperature, the second The second layer: surface veneer 2; here the surface veneer 2 is made of piano black veneer, the third layer: wood glue paper 3 (glue); the fourth layer: poplar wood 4; here poplar wood 4 uses Anlige veneer, the fifth layer: wood Tape 3; Layer 6: Poplar 4; Layer 7: Wood Tape 3 (glue); Layer 8: Poplar 4; Layer 9: Aluminum Tape 5 (glue); Layer 4: Poplar 4 is horizontal arrangement, the sixth layer: poplar 4 is vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com