Nitrogen-filling welding method for copper tube and nitrogen-filling welding control device

A copper tube and nitrogen technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as capillary or expansion valve blockage, non-heating, compressor cylinder jam, etc., to improve quality, avoid waste, flow rate proper effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

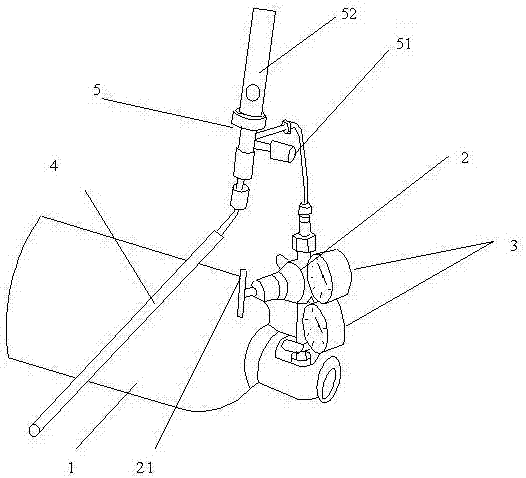

[0025] Attached below figure 1 , the welding control device of the copper tube nitrogen filling welding method provided by the present invention will be described in detail. The operation method of copper pipe nitrogen filling welding is as follows:

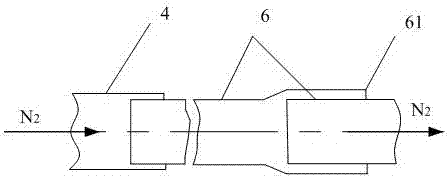

[0026] The nitrogen supply pressure is set below 0.05MPa; the nitrogen flow value is set, the precondition is that the diameters of the welded copper pipes from the inlet to the outlet should be the same, and the ports of the pipes are open. When the diameter of the copper pipe is 25.4mm and the wall thickness is 1mm, the cross-sectional area of the pipe is 3.14*(25.4 / 2-1) 2 =429.8mm 2 , The nitrogen flow rate is proportional to the cross-sectional area of the copper tube, thus, the calculated value of the nitrogen flow rate is about 4L / min. The flow rate of nitrogen filling is not specially stipulated, and the implementation value of the flow rate can be optimized according to the experimental results. Using this flow rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com