Automatic pattern piece gluing device for evaporative pattern for casting

A gluing device and technology of lost foam, which is applied to the device and coating of the surface coating liquid, can solve the problems of inaccurate gluing line, low model strength, uneven gluing amount, etc., and achieve cost saving The effect of glue quantity, convenient manufacturing and replacement, and wide product adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be described below in conjunction with specific embodiments.

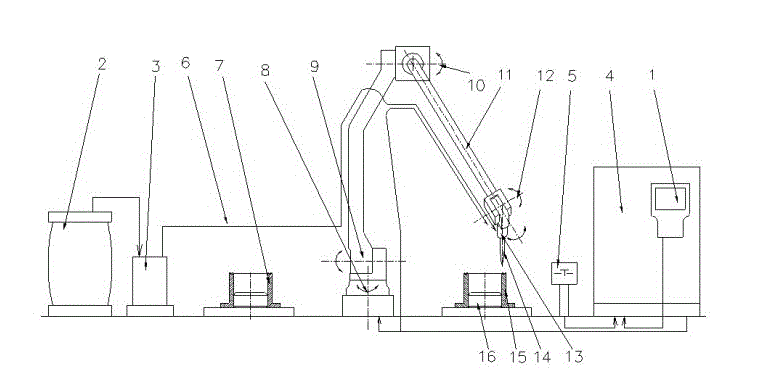

[0024] like figure 1 Shown is a schematic structural view of the automatic gluing device for lost foam dies of the present invention. The automatic gluing device of the present invention comprises: an automatic adhesive conveying system, a gluing robot system, a numerical control operating system, and a die positioning tool. After the lost foam die is positioned by the die positioning tool, the adhesive glue is evenly applied to the lost foam die through the control of the automatic glue delivery system and the glue coating robot system by the numerical control operating system, and then the lost foam die is taken out , and the mating dies are bonded together to form a complete lost foam shape.

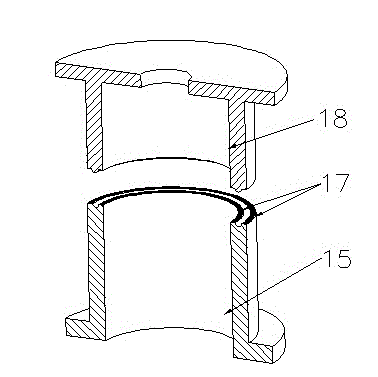

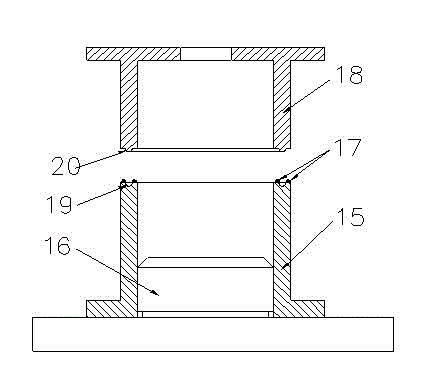

[0025] like figure 1 As shown, the automatic gluing device for the lost foam die sheet of the present invention, the die sheet includes: the first gluing die sheet 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com