Lithium secondary battery and method for producing same

A technology of lithium secondary battery and lithium quantity, which is applied in the direction of secondary battery, electrolyte storage battery manufacturing, electrode manufacturing, etc., can solve the problem of irreversible capacity reduction of positive electrode, achieve short charge and discharge cycle life, easy miniaturization, and suppress electrolyte The effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach )

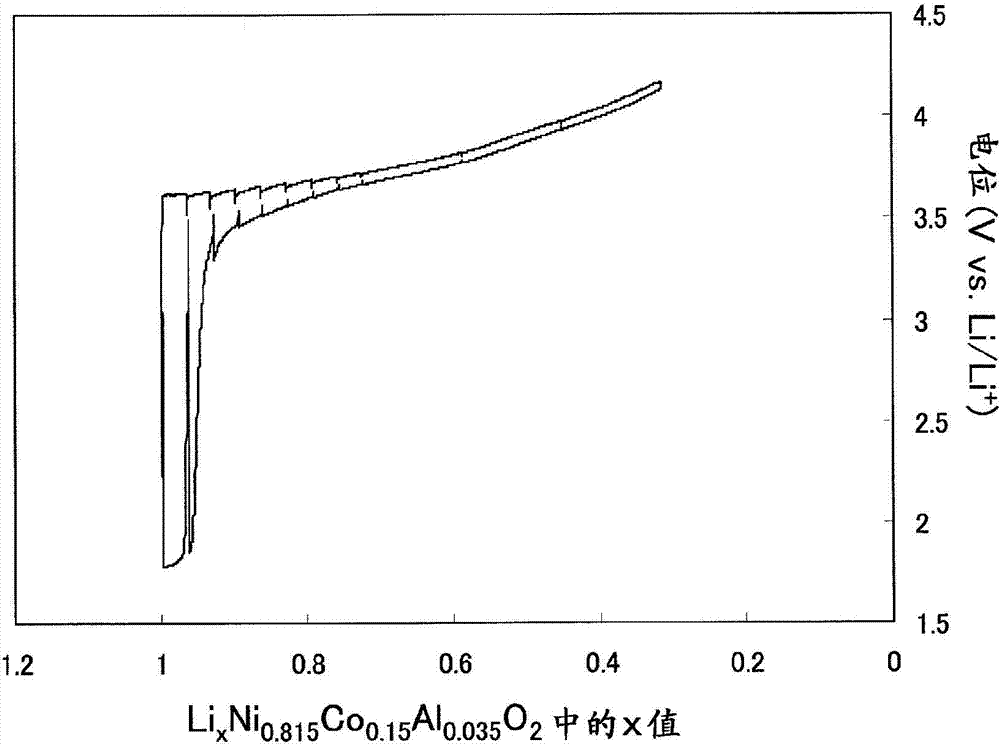

[0183] Hereinafter, the configuration of the lithium secondary battery according to the embodiment of the present invention will be described with reference to the drawings. The lithium secondary battery of this embodiment contains a lithium-nickel composite oxide having substantially irreversible capacity as a positive electrode active material. The particle properties, preferred composition, and the like of the positive electrode active material are as described above. The material of the negative electrode active material is not particularly limited, but for example, carbon-based materials such as the above-mentioned graphite, SiO X and other silicon-based materials. In addition, lithium is stored in advance in the negative electrode active material. The amount of lithium stored in advance is set so that the amount of lithium that can be released in the negative electrode is greater than the irreversible capacity of the lithium secondary battery in a fully discharged stat...

Embodiment 4

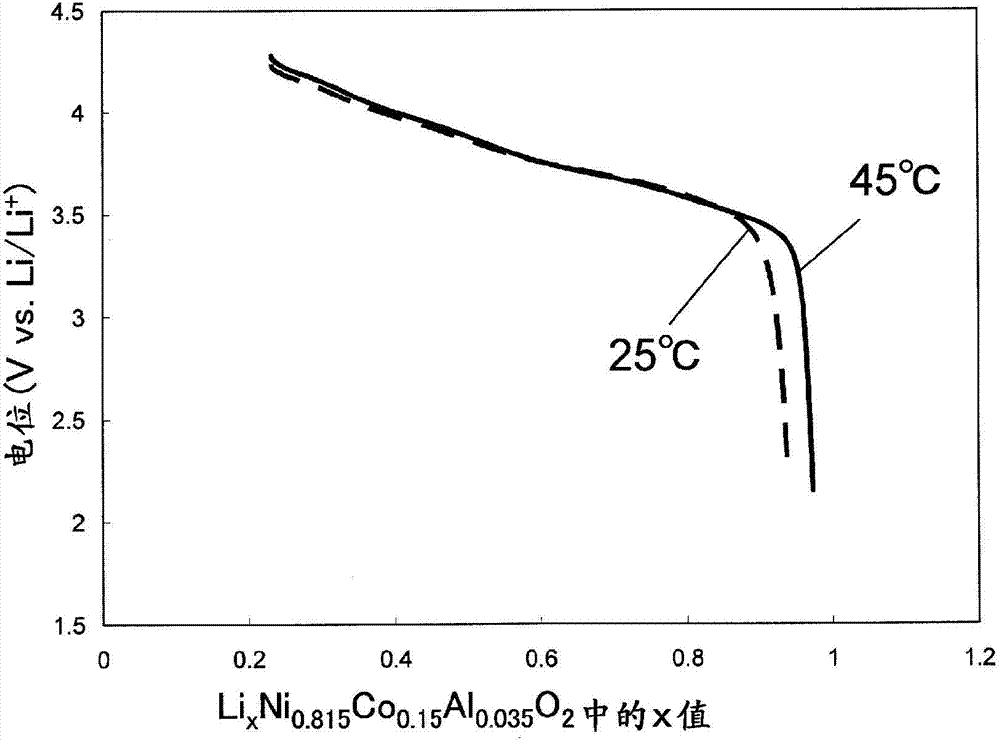

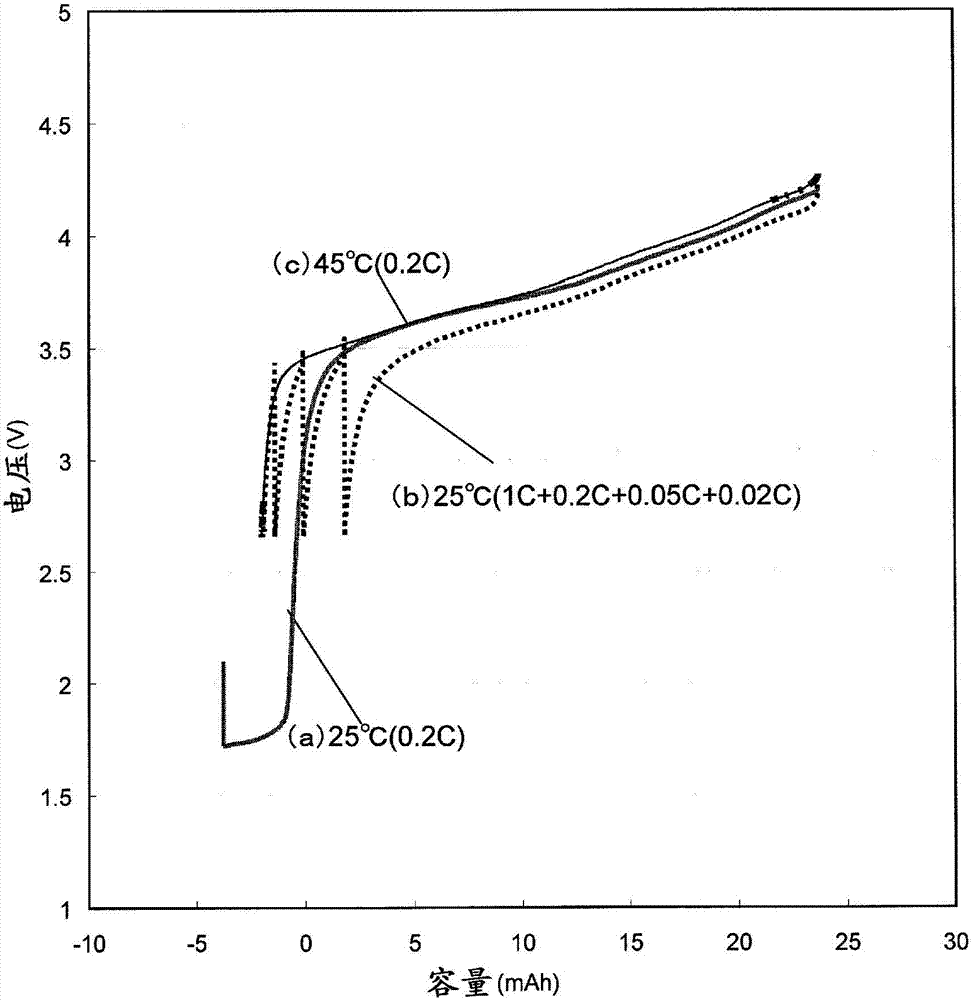

[0315] Example 4 has the same configuration as Example 3 except that the packing density of the positive electrode is high. Example 4 also shows the same potential behavior as Example 3, and the increase rate of the utilization capacity caused by increasing the ambient temperature (25°C → 45°C) becomes larger than the increase rate (6%) in Example 3 . On the other hand, when the filling density of the positive electrode was reduced (Example 5), the increase rate of the utilization capacity became smaller than that of Example 3. From this result, it can be seen that the battery capacity at high temperature can be more effectively improved by controlling the packing density of the positive electrode in the range of, for example, more than 3.0 g / cm3 and less than 4.0 g / cm3.

[0316] In addition, Example 6 has the same configuration as Example 3 except that the primary particle diameter of the positive electrode is increased. Example 6 also shows the same potential behavior as E...

Embodiment 7

[0320] In Example 7 and Example 3, only the lithium pre-storage method for the silicon-based negative electrode is different. From the comparison of these evaluation results, it can be confirmed that even if the lithium pre-storage method is different, the increase rate of the utilization capacity accompanying the increase of the ambient temperature is about the same level, and the effect of achieving a high capacity at high temperature can be obtained. In addition, when vacuum evaporation is used to pre-storage lithium (Example 3), the storage and release of lithium become smooth, and the polarization of charge and discharge becomes smaller compared with the case of electrochemical storage (Example 7), and it can be obtained High cycle characteristics.

[0321] In addition, in Examples 3 to 7 using nickel-based lithium-containing composite oxides as the positive electrode active material, compared with Example 8 using cobalt-based lithium-containing composite oxides, the incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com