Boiler having integrated nitrogen tank and heat exchanger

A technology of heat exchanger and nitrogen, which is applied in the field of boilers, can solve problems such as unit price increase and hot water cannot flow out immediately, and achieve the effects of improving heat exchange performance, reducing production unit price, and simplifying the heating water circulation structure and the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

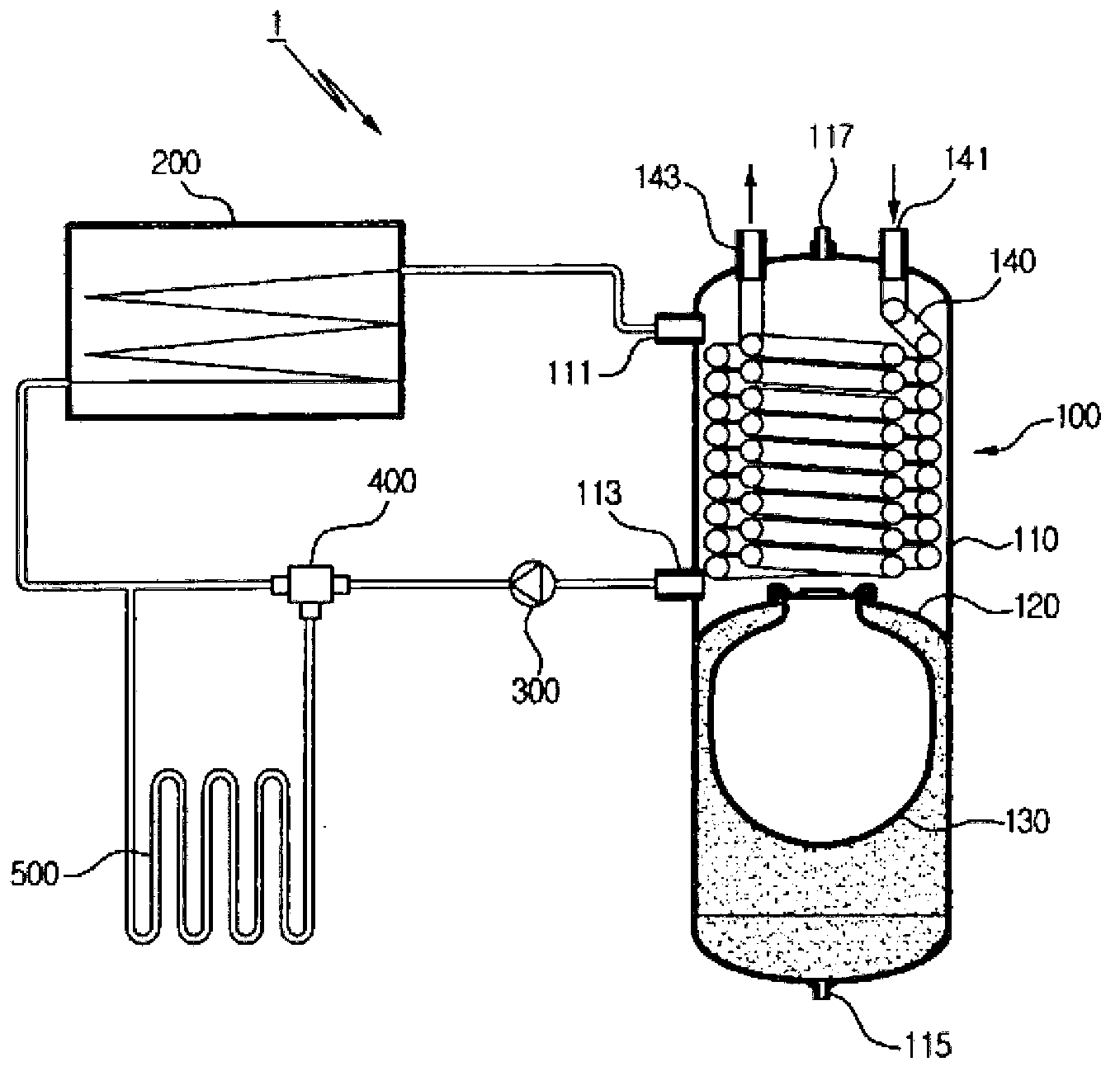

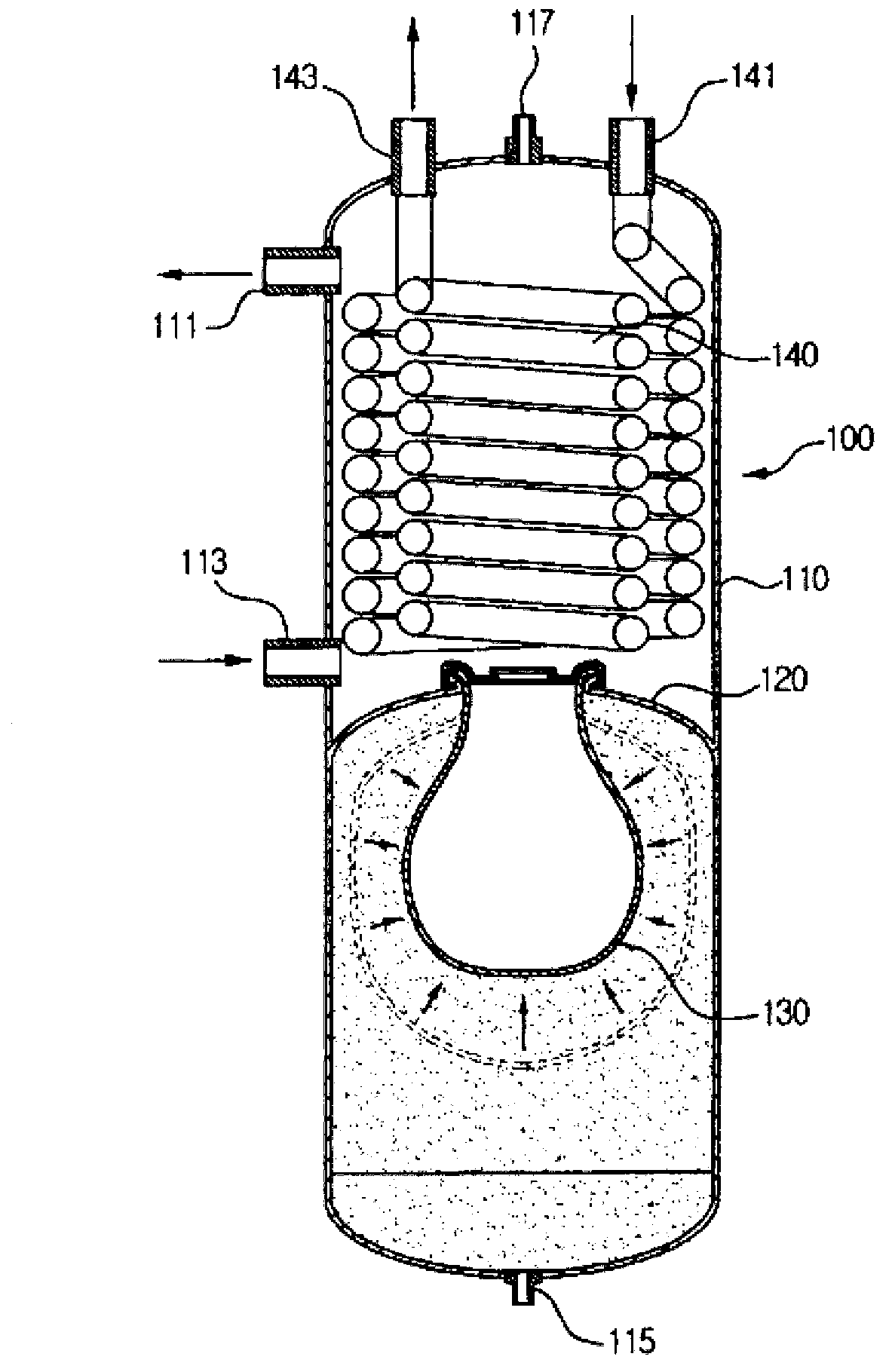

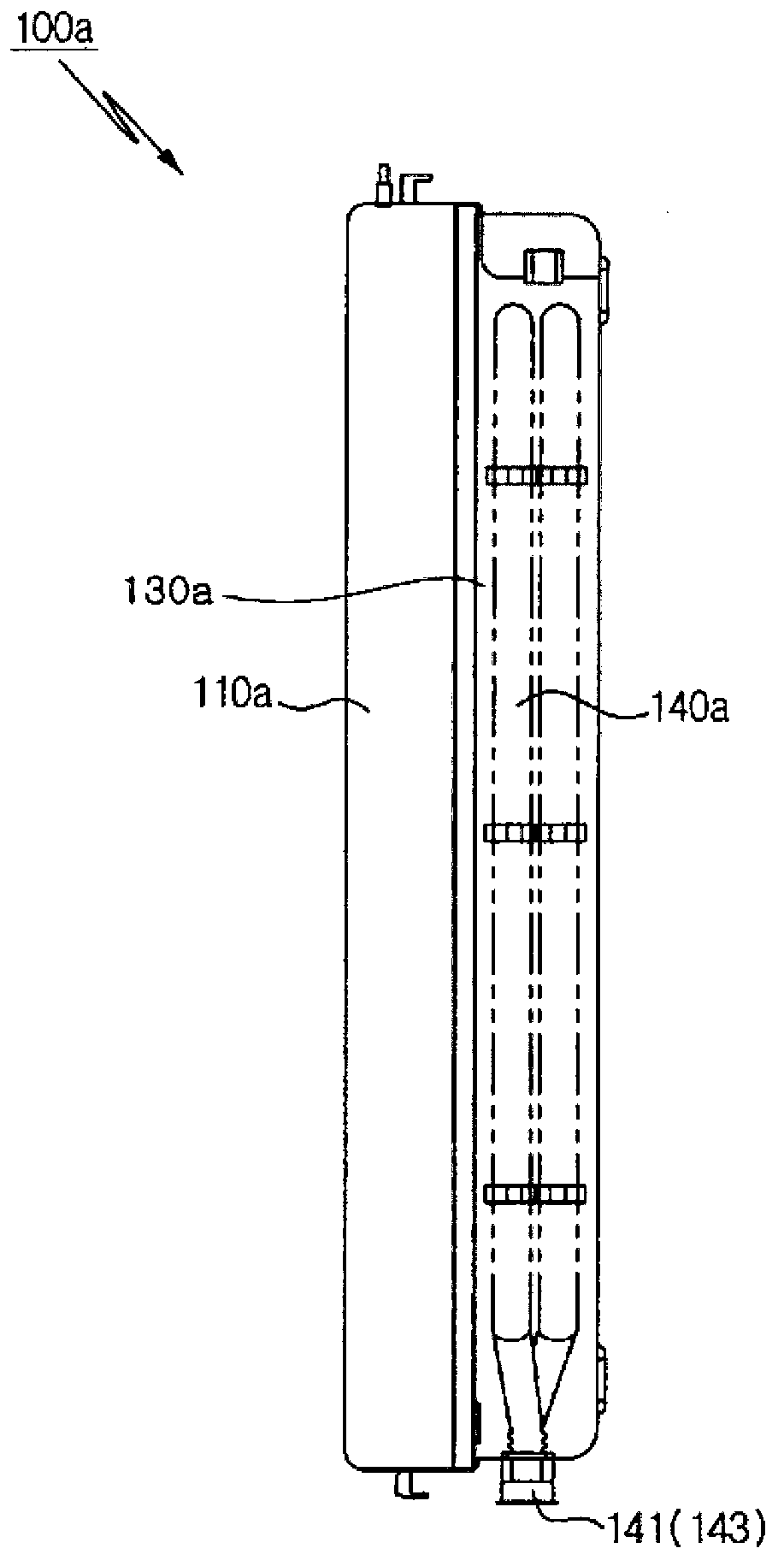

[0025] figure 1 A schematic diagram schematically depicting the internal cross-sectional structure of the boiler (100) of the present invention, figure 2 It is a schematic diagram depicting a schematic structure of a boiler system (1) to which the boiler (100) of the present invention is applied.

[0026] As shown in the figure, the boiler (100) of the present invention includes the following structure, the casing (110), the nitrogen filling box (120) arranged in the lower part of the casing (110), and the nitrogen filling box (120) is arranged inside and An elastic pocket (130) that can achieve elastic deformation in volume according to the inflow and outflow of warm water, and a warm water heat exchanger (140) configured on the upper part of the casing (110) for adjusting the temperature of warm water.

[0027] The inside of the casing (110) has space for accommodating the nitrogen filling tank (120) and the warm water heat exchanger (140), and also has space for heating w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com