A uniformly modified porous cathode material with controllable surface structure and preparation method thereof

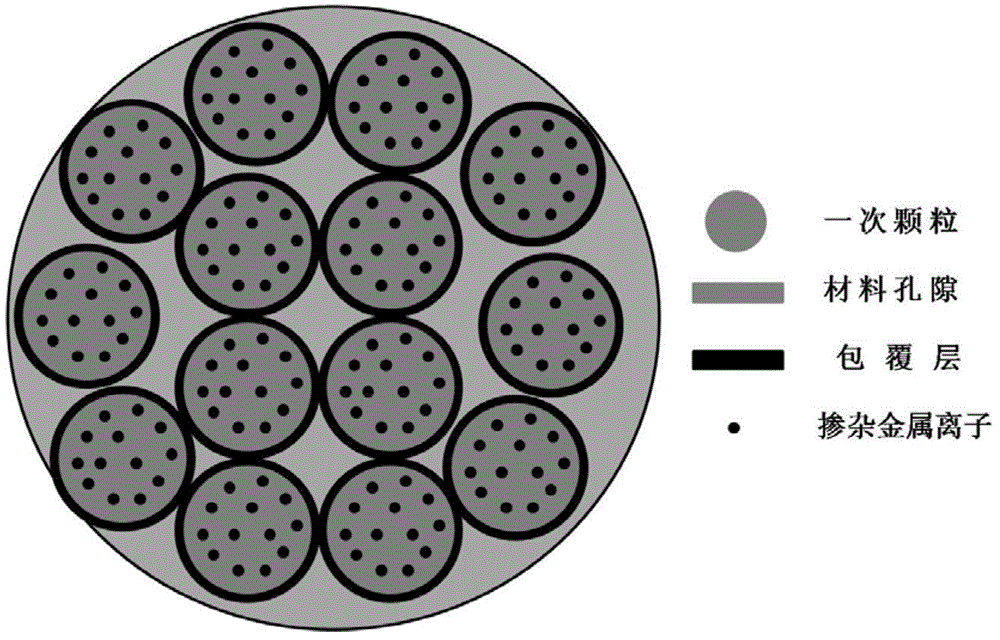

A technology of surface structure and cathode material, applied in the field of preparation of new energy materials, can solve the problems of uneven surface modification and uneven modification of porous cathode materials, improve high-temperature cycle performance and thermal stability, and suppress interfacial side reactions. , Solve the effect of doping uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

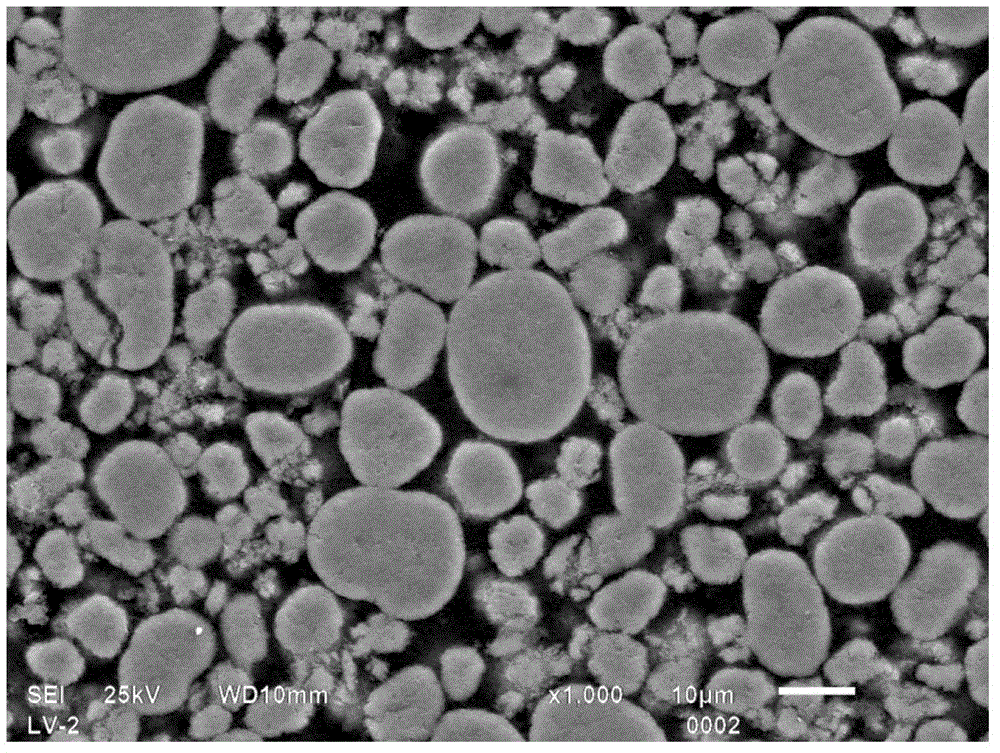

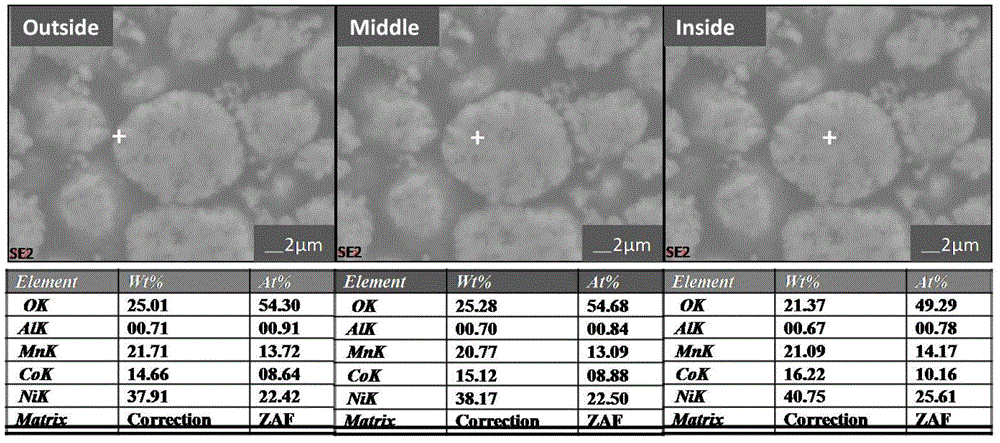

[0037] The total concentration of the prepared solution is 2mol / L NiSO 4 、CoSO 4 , MnSO 4 The mixture liquid, where n (Ni) :n (Co) :n (Mn) =5:2:3, then in N 2 4mol / L NaOH and 1mol / L NH 3 ·H 2 The mixed lye of O and the above mixed material liquid are added to the reaction kettle equipped with deionized water at the same time, the flow rate of the lye is adjusted to make the reaction solution pH=10.5, the reaction temperature is controlled at 50 ° C and kept stirring, when the remaining reaction material liquid When the volume is 90% of the volume of the starting material, start adding Al with a concentration of 0.02M 2 (SO 4 ) 3 After the reaction, filter and wash and dry at 100°C to obtain a porous hydroxide precursor A1 with uniform surface aluminum modification (such as figure 1 shown); take precursor A140g, and 16.9gLi 2 CO 3 After mixing, carry out primary sintering at a temperature of 920°C and keep it warm for 20 hours to obtain a primary sintering product B...

Embodiment 2

[0039] The total concentration of the prepared solution is 2mol / L NiSO 4 、CoSO 4 , MnSO 4 The mixture liquid, where n (Ni) :n (Co) :n (Mn) =5:2:3, then in N 2 4mol / L NaOH and 1mol / L NH 3 ·H 2 The mixed lye of O and the above mixed material liquid are added to the reaction kettle equipped with deionized water at the same time, the flow rate of the lye is adjusted to make the reaction solution pH=10.5, the reaction temperature is controlled at 50 ° C and kept stirring, when the remaining reaction material liquid When the volume is 60% of the volume of the starting material, start adding Al with a concentration of 0.02M 2 (SO 4 ) 3 Aqueous solution, filtered and washed after the reaction and dried at 100°C to obtain porous hydroxide precursor A2 with uniform surface aluminum modification; take 240g of precursor A, and 16.9g Li 2 CO 3 After mixing, carry out primary sintering, the sintering temperature is 920°C, keep warm for 20 hours, and obtain the primary sintering p...

Embodiment 3

[0041] The total concentration of the prepared solution is 2mol / L NiSO 4 、CoSO 4 , MnSO 4 The mixture liquid, where n (Ni) :n (Co) :n (Mn) =5:2:3, then in N 2 4mol / L NaOH and 1mol / L NH 3 ·H 2 The mixed lye of O and the above mixed material liquid are added to the reaction kettle equipped with deionized water at the same time, the flow rate of the lye is adjusted to make the reaction solution pH=10.5, the reaction temperature is controlled at 50 ° C and kept stirring, when the remaining reaction material liquid When the volume is 30% of the volume of the starting material, start adding Al with a concentration of 0.02M 2 (SO 4 ) 3 Aqueous solution, filtered and washed after the reaction and dried at 100°C to obtain porous hydroxide precursor A3 with uniform surface aluminum modification; take 340g of precursor A, and 16.9g Li 2 CO 3 After mixing, carry out primary sintering, the sintering temperature is 920°C, and keep warm for 20 hours to obtain the primary sintering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com