Fracture and sand prevention integrated completion pipe string and application method thereof

A completion string, fracturing sand control technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of increased completion time, increased operation procedures, increased completion costs, etc., to reduce Operating cost, saving operating time, and flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

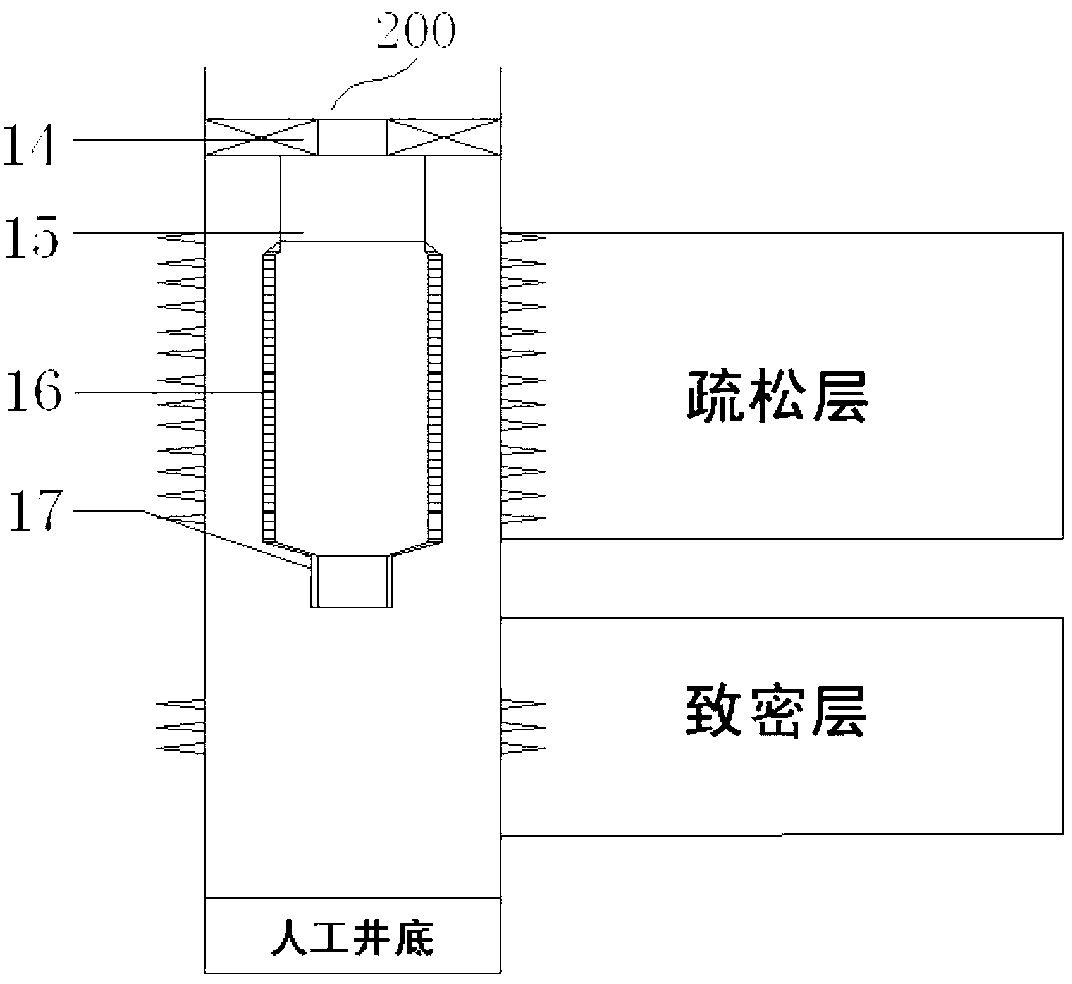

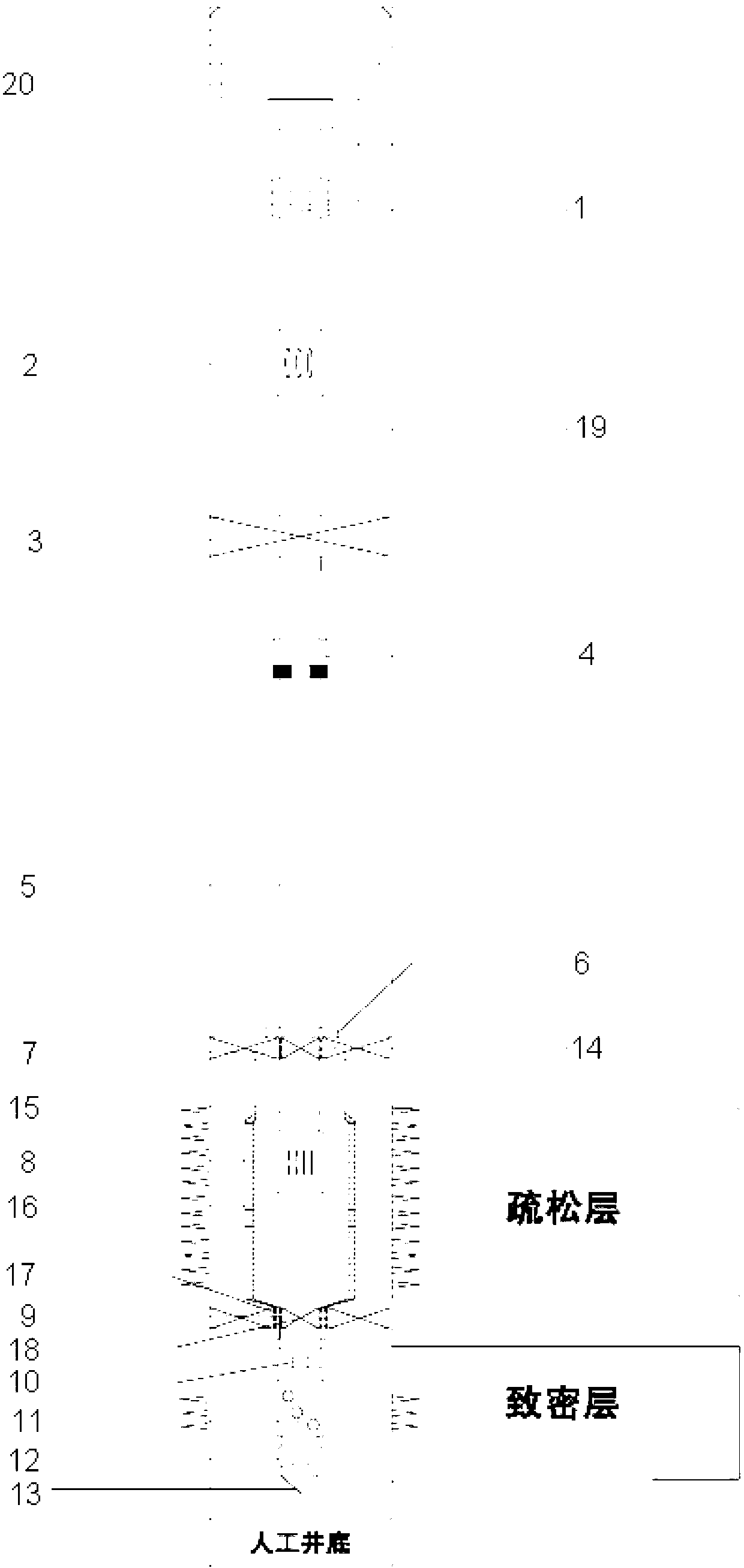

[0022] Such as figure 1 , figure 2 As shown, the present invention includes a fracture production string 100 and a sand control string 200 .

[0023] Such as figure 1 As shown, the fracturing production string 100 includes a safety valve 1, a first sliding sleeve 2, a production packer 3, a first seating joint 4, a tubing 5, a positioning seal 6, a first insertion seal 7, and a second sliding sleeve 8 , The second insertion seal 9, the second seating joint 10, the perforated pipe 11, the NO-GO seating joint 12 and the guide shoe 13. Among them, the safety valve 1 is arranged on the upper part of the oil pipe 5 , and the first sliding sleeve 2 , the production packer 3 , the first seating joint 4 and the positioning seal 6 are sequentially arranged on the oil pipe 5 below the safety valve 1 at intervals. The first insertion seal 7 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com