One-time multi-layer gravel packing operation method for long-span perforation section

A technology of gravel packing and perforation section, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc. It can solve the problems of inability to complete the super-long operation of the center pipe and large fluid friction, and increase the cumulative construction length , Reduce the effect of liquid circulation friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

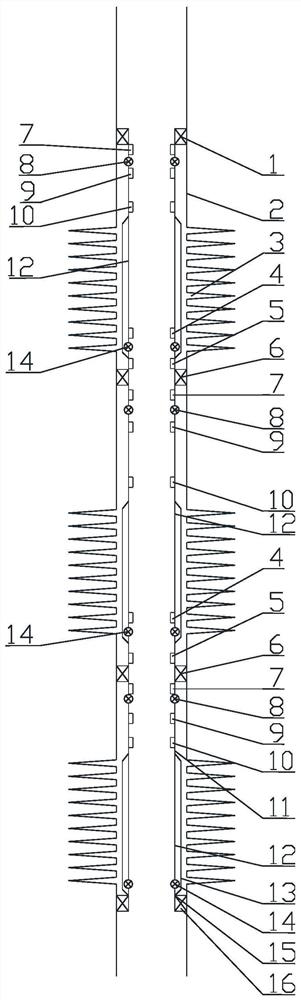

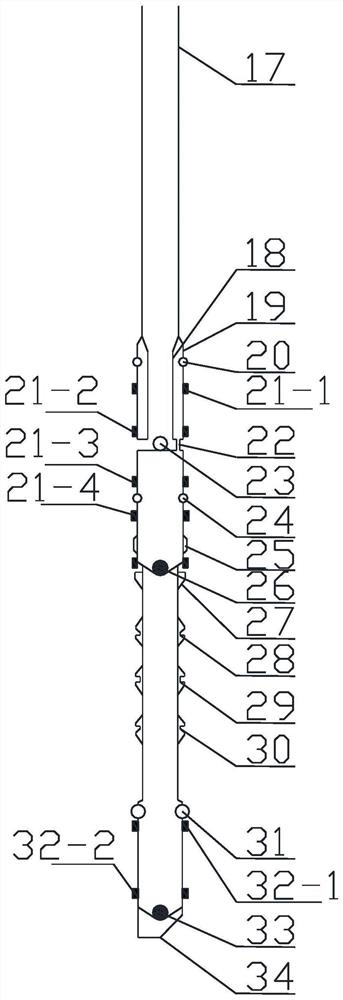

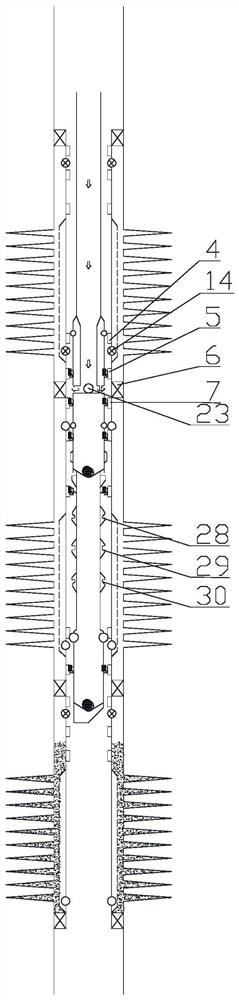

[0065] see Figure 1 to Figure 7 , a multi-layer gravel packing operation method in a long-span perforation section, the long-span perforation section is provided with an upper perforation layer, zero to multiple middle perforation layers and a bottom perforation layer, the operation method adopts the following step:

[0066] 1) Set a grit settling packer 16 inside the casing 1 and at the bottom of the long-span perforation section.

[0067] 2) Assemble the top packer assembly of the outer pipe string and the main part of the outer pipe string on the ground, and then hang the main part of the outer pipe string at the wellhead; run the service pipe string into the outer pipe string while assembling In the main part of the string, in the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com