Method for simulating coal seam mining by using rubber hydraulic bags

A mining method and rubber bag technology, applied in ground mining, earth square drilling, underground mining, etc., can solve problems such as distortion of movement and deformation of the overlying rock layer in the goaf, waste of test personnel time, and collapse of the test model. Ideal results, time-saving, simple and convenient methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

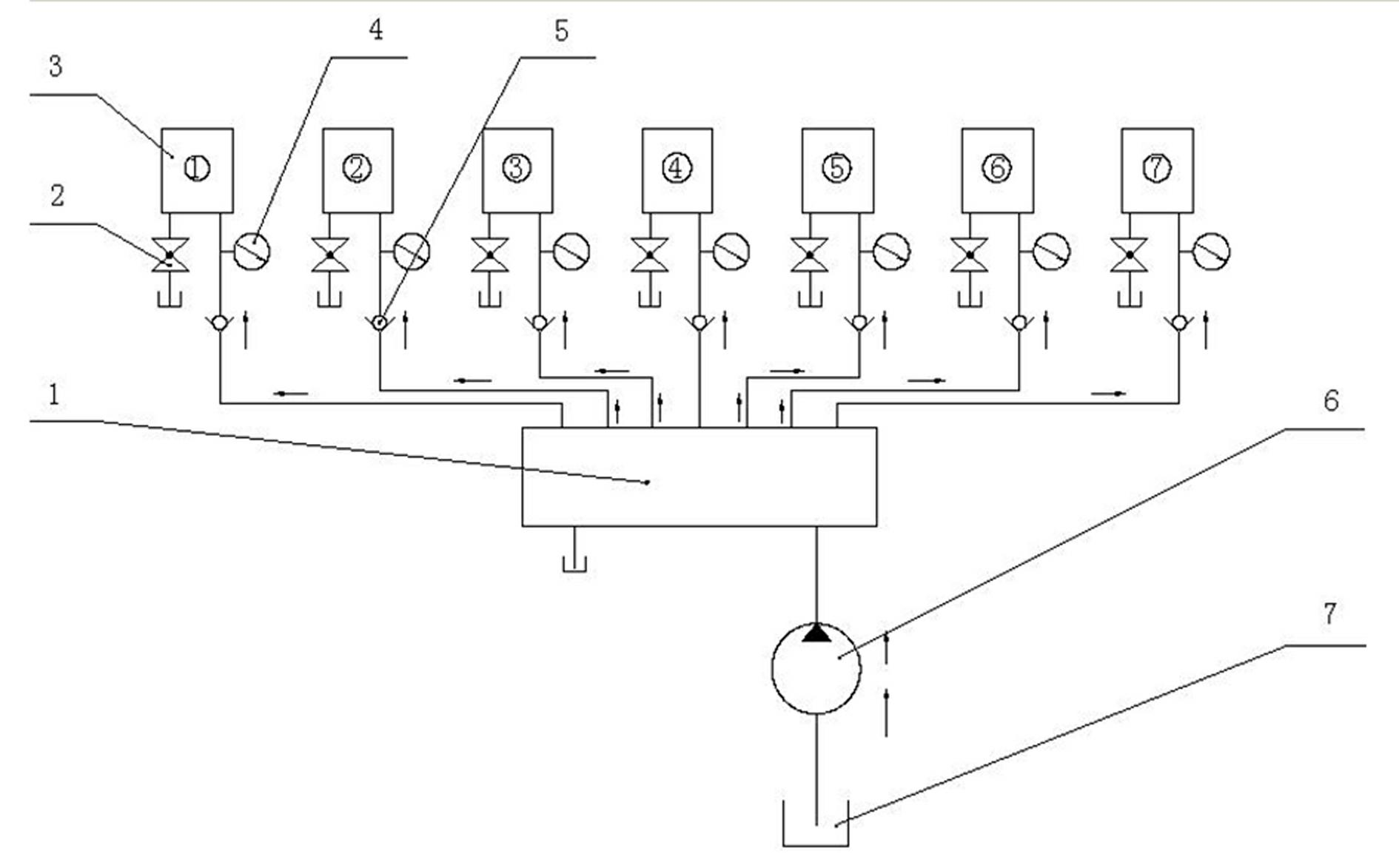

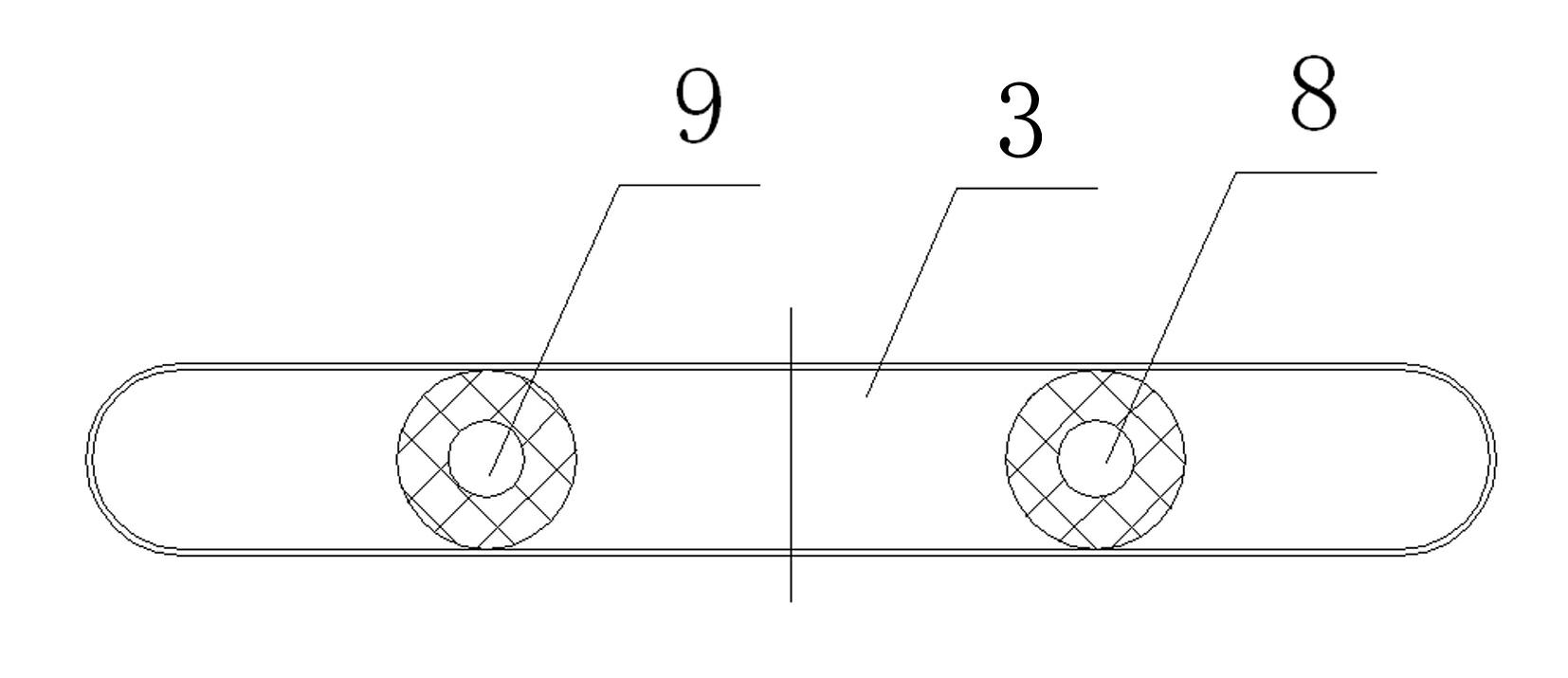

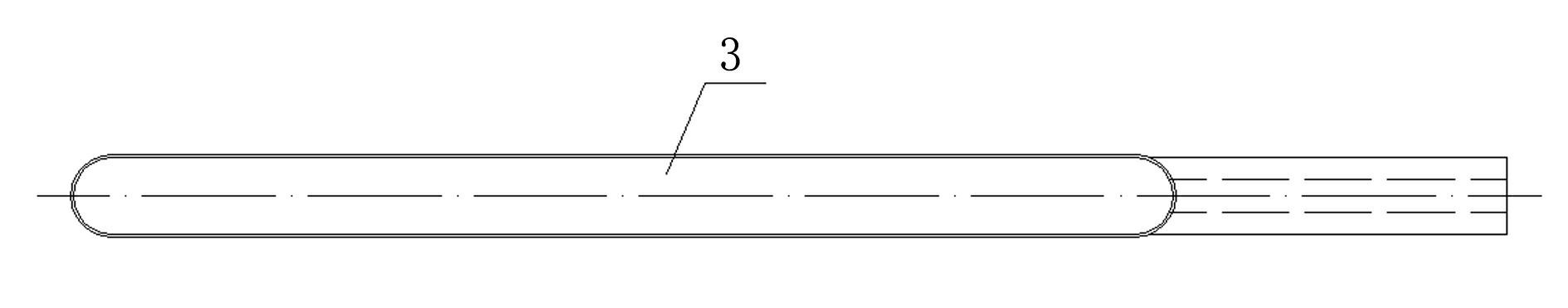

[0018] A method for simulating coal seam mining with a rubber hydraulic bag, using a rubber hydraulic bag to simulate a coal seam mining device, such as figure 1 As shown in -4, the device includes a model frame on which a group of rubber hydraulic bags 3 are horizontally arranged, and an overlying rock layer is laid on the top of the rubber hydraulic bags 3; each rubber hydraulic bag 3 is provided with a liquid inlet 8 and the liquid outlet 9, the liquid inlet 8 of the rubber hydraulic bag 3 is connected to the one-way valve 5, the expansion quick switch 1, the pump 6, the liquid tank 7 sequentially through the pipeline, and the liquid outlet 9 of the rubber hydraulic bag 3 is passed through the pipeline Connect the ball valve 2 and the liquid storage tank in sequence. A pressure gauge 4 is provided on the pipeline between the rubber hydraulic bag 3 and the one-way valve 5 . The rubber hydraulic bag 3 is a rectangular double-layer cloth bag structure, and one side of the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com