Aluminum alloy door and window frame and installation method thereof

A technology for aluminum alloy doors and windows, doors and windows, applied in the direction of base frames, windows/doors, building components, etc., can solve problems such as uncontrollable, loose doors and windows, profile pollution and corrosion, etc., to achieve enhanced safety and convenience, and to maintain safety and stabilization, physical performance enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with specific examples.

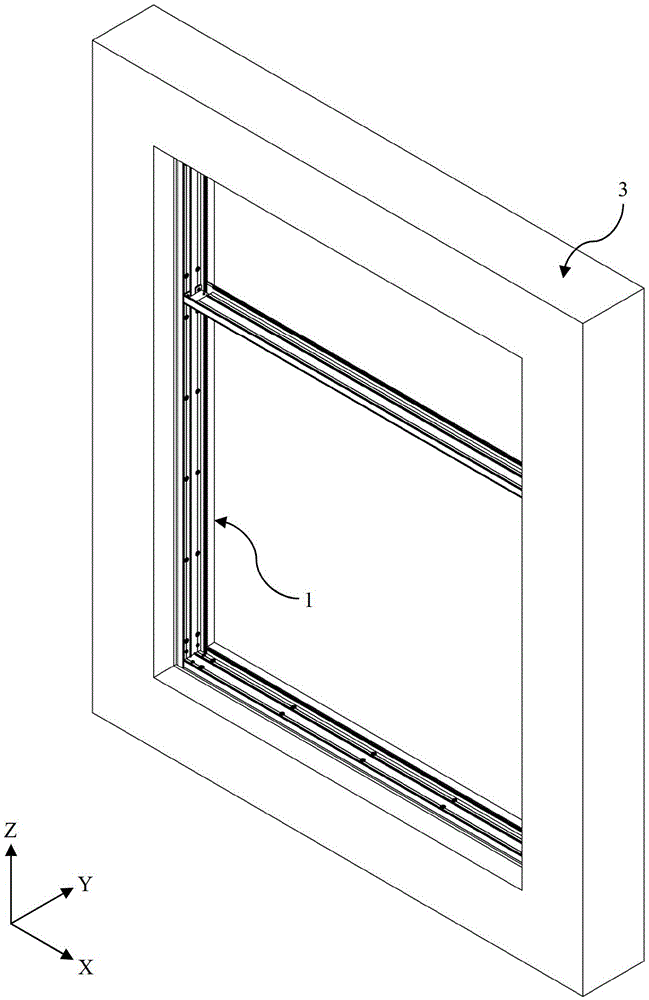

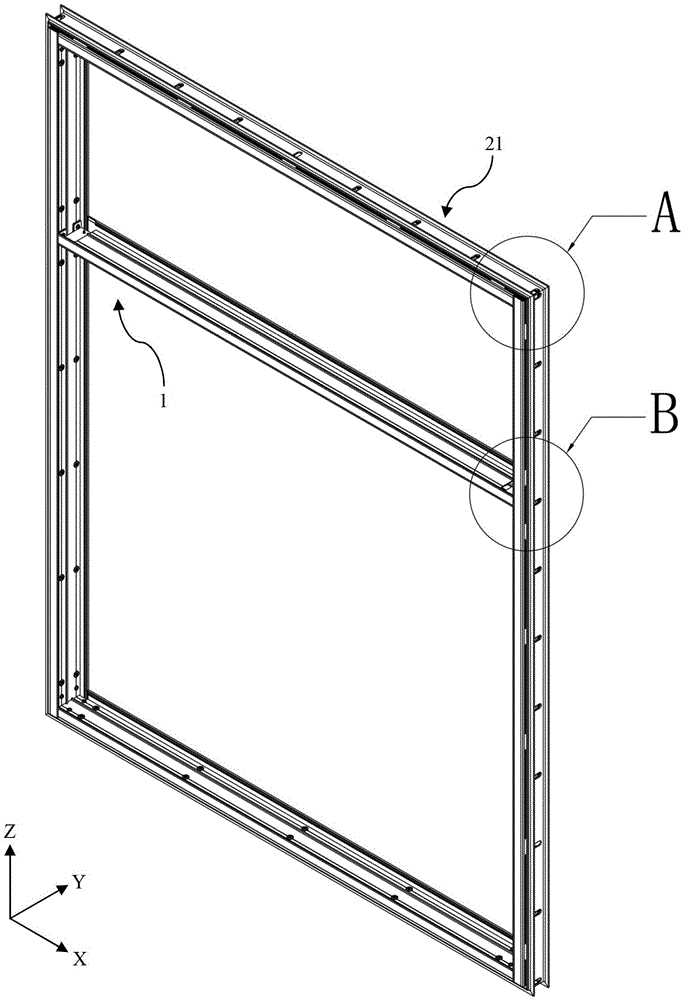

[0070] see Figure 1-Figure 6 As shown, the aluminum alloy door and window frame installation structure in the present invention includes a door and window hole 3 on the building body and an aluminum alloy door and window frame 1 fixed in the door and window hole 3; the aluminum alloy door and window frame installation structure in the present invention also includes a The chassis 2 is installed, and the aluminum alloy door and window frame 1 is installed in the door and window hole 3 of the main body of the building through the chassis 2;

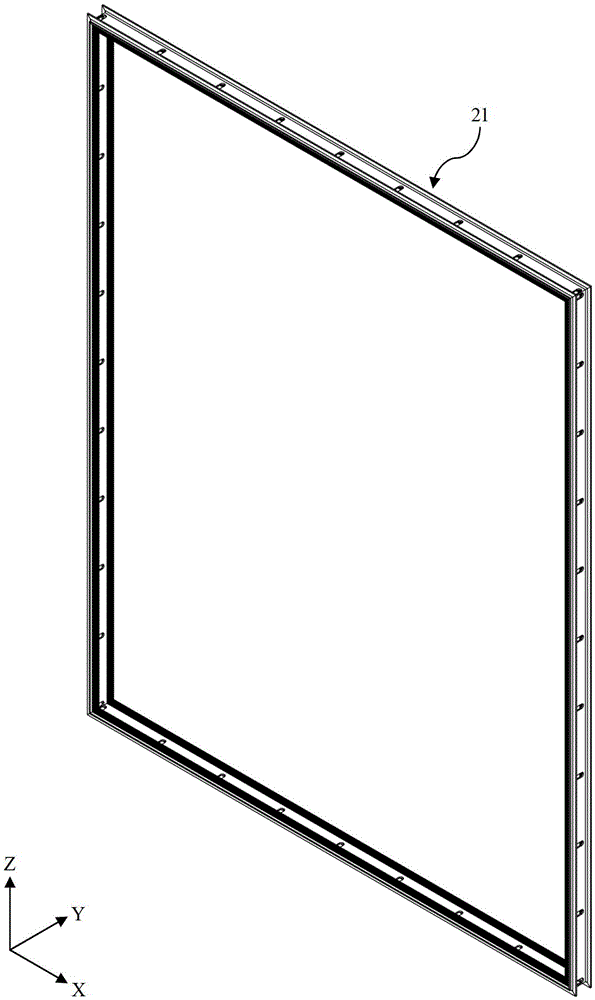

[0071] The installation chassis 2 includes an installation frame 21, a first installation module 2131, and a second installation module 22; as a preferred embodiment of the present invention, the installation frame 21 can adopt a metal sub-frame structure as shown in the figure, which includes a bottom plate 211 and a bottom plate Extend ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com