Automatic airing system for grains

A kind of grain and automatic technology, which is applied in the direction of drying and preserving seeds, can solve the problems of food nutrition damage, time-consuming and labor-consuming, and affect food safety, so as to maintain safety and sanitation, improve labor efficiency, and have high social significance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

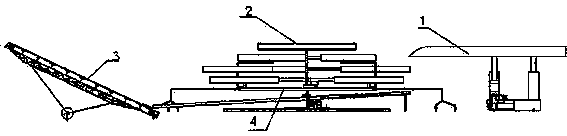

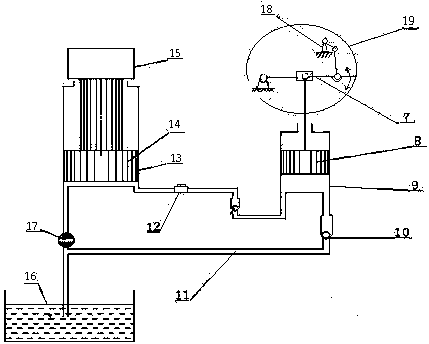

[0014] Accompanying drawing is a kind of specific embodiment of the present invention.

[0015] The automatic grain drying system of the present invention is characterized in that it comprises a lifting device 1 , a drying device 2 , and a grain harvesting device 3 .

[0016] The lifting device 1 is composed of a hydraulic system 5 and a crank rocker mechanism 19. The hydraulic system 5 includes a large hydraulic cylinder and a small hydraulic cylinder. , the large hydraulic cylinder body 13 is connected to the oil tank through the oil guide pipe 11 equipped with the throttle valve 17, and the small hydraulic cylinder body 9 is connected to the oil tank through the oil guide pipe 11 equipped with the check valve 10, the large and small The hydraulic cylinder and the oil guide pipe 11 integrally form a circulating circuit system of hydraulic oil; the upper end of the large hydraulic cylinder piston 14 is connected with a grain storage basket 15, and the small hydraulic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com