Preparation method of coating type far infrared radiation preservation packing paperboard

A far-infrared radiation, fresh-keeping packaging technology, applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of the complexity of the corrugated box process, potential safety hazards, and high manufacturing costs, and achieve good fresh-keeping effect, simple process, and manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

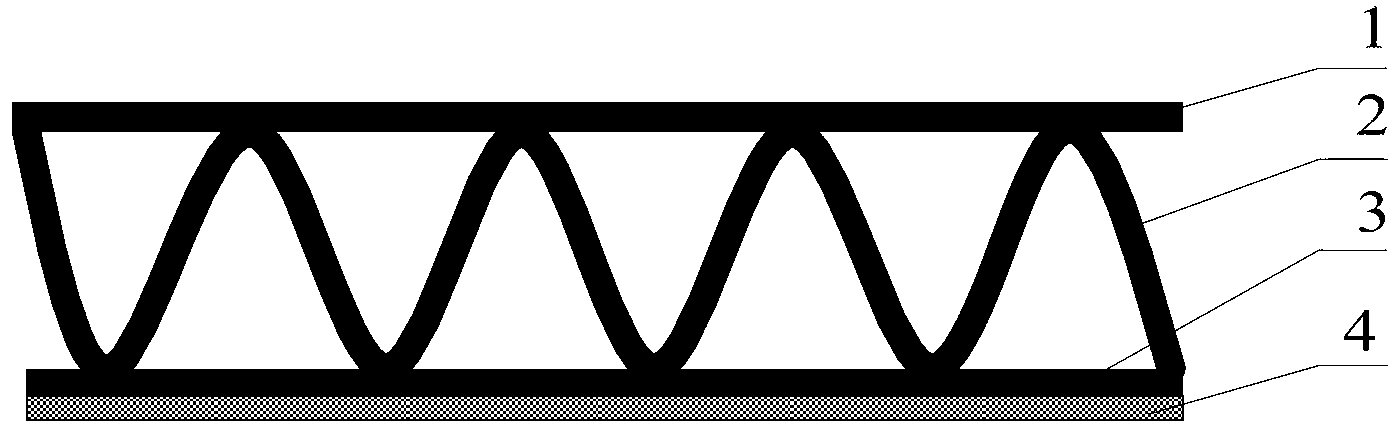

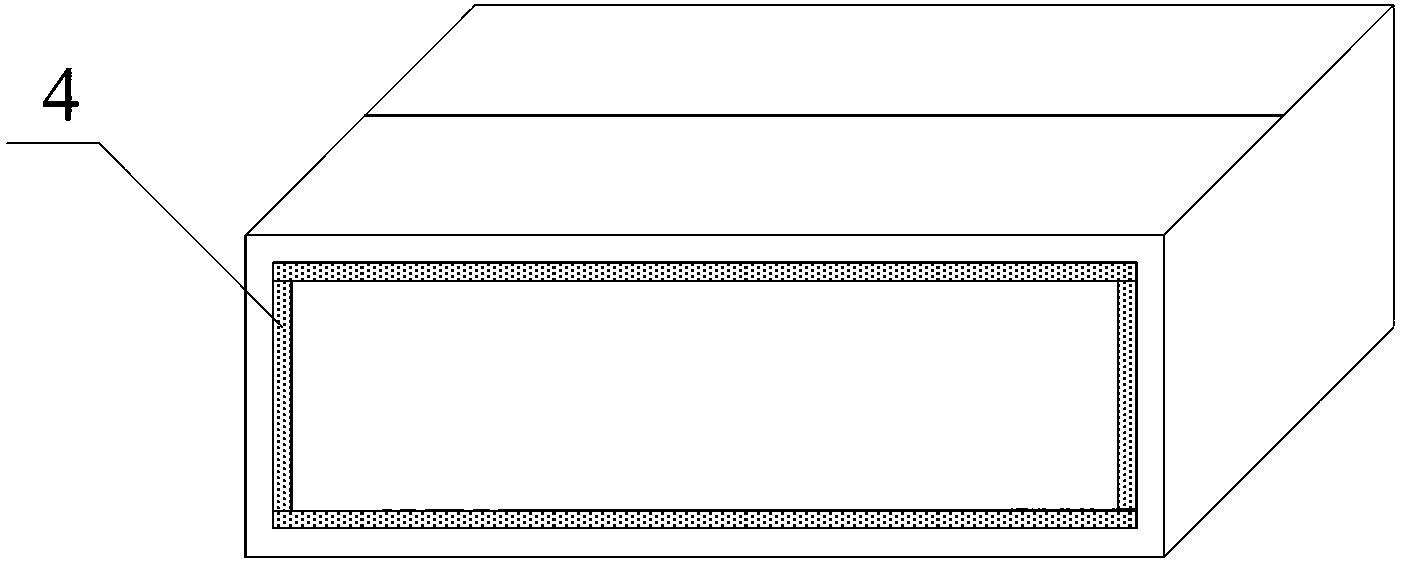

[0020] Embodiment one: a kind of preparation method of coating type far-infrared radiation fresh-keeping packaging cardboard comprises the following process steps:

[0021] (1) Coating preparation: mix and stir the far-infrared ceramic powder, binder and dispersant in a mass ratio of 1:9:7, and let it stand for 20 minutes to obtain a far-infrared radiation coating; the binder is polyvinyl acetate Emulsion (white latex), the dispersant is a sodium polyphosphate solution with a mass percent concentration of 0.02%, and the fineness of the far-infrared ceramic powder is 1 micron;

[0022] (2) Coating: Evenly coat the far-infrared coating on the surface of the corrugated paper, and the coating amount is 850g / square meter. Roughness: In this embodiment, the surface after coating is controlled to have no granular protrusions or cavities with a diameter greater than 1mm, and there will be no powder falling after coating;

[0023] (3) Dry the corrugated paper coated with the far-infra...

Embodiment 2

[0024] Embodiment 2: A kind of preparation method of coating type far-infrared radiation fresh-keeping packaging cardboard comprises the following process steps:

[0025] (1) Coating preparation: mix and stir the far-infrared ceramic powder, binder and dispersant according to the mass ratio of 1:11:8, and let it stand for 25 minutes to obtain the far-infrared radiation coating; the binder is modified starch; Described dispersant is the sodium polyphosphate solution that mass percent concentration is 0.03%; The fineness of described far-infrared ceramic powder is 2.5 microns;

[0026] (2) Coating: Evenly coat the far-infrared coating on the surface of the corrugated paper, and the coating amount is 950g / square meter. In order to control the uniformity of coating and avoid powder falling, it is necessary to control the coating surface to have a certain Roughness: In this embodiment, the surface after coating is controlled to have no granular protrusions or cavities with a diamet...

Embodiment 3

[0028] Embodiment three: a kind of preparation method of coating type far-infrared radiation fresh-keeping packaging cardboard, comprises the following process steps:

[0029] (1) Coating preparation: mix and stir the far-infrared ceramic powder, binder and dispersant according to the mass ratio of 1:10:7.5, and let it stand for 24 minutes to obtain the far-infrared radiation coating; the binder is polyvinyl alcohol The dispersant is a sodium polyphosphate solution with a mass percent concentration of 0.025%; the fineness of the far-infrared ceramic powder is 2 microns;

[0030] (2) Coating: Evenly coat the far-infrared coating on the surface of the corrugated paper, and the coating amount is 900g / square meter. In order to control the uniformity of coating and avoid powder falling, it is necessary to control the coating surface to have a certain Roughness: In this embodiment, the surface after coating is controlled to have no granular protrusions or cavities with a diameter gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com