Heavy environmentally-friendly rubber oil and preparation method thereof

An environmentally friendly rubber oil and heavy-duty technology, applied in the field of petrochemical industry, can solve the problems of shortage of raw materials and high prices, and achieve the effects of improving solvency, increasing added value, and reducing the amount of furfural

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, the preparation of environment-friendly rubber oil

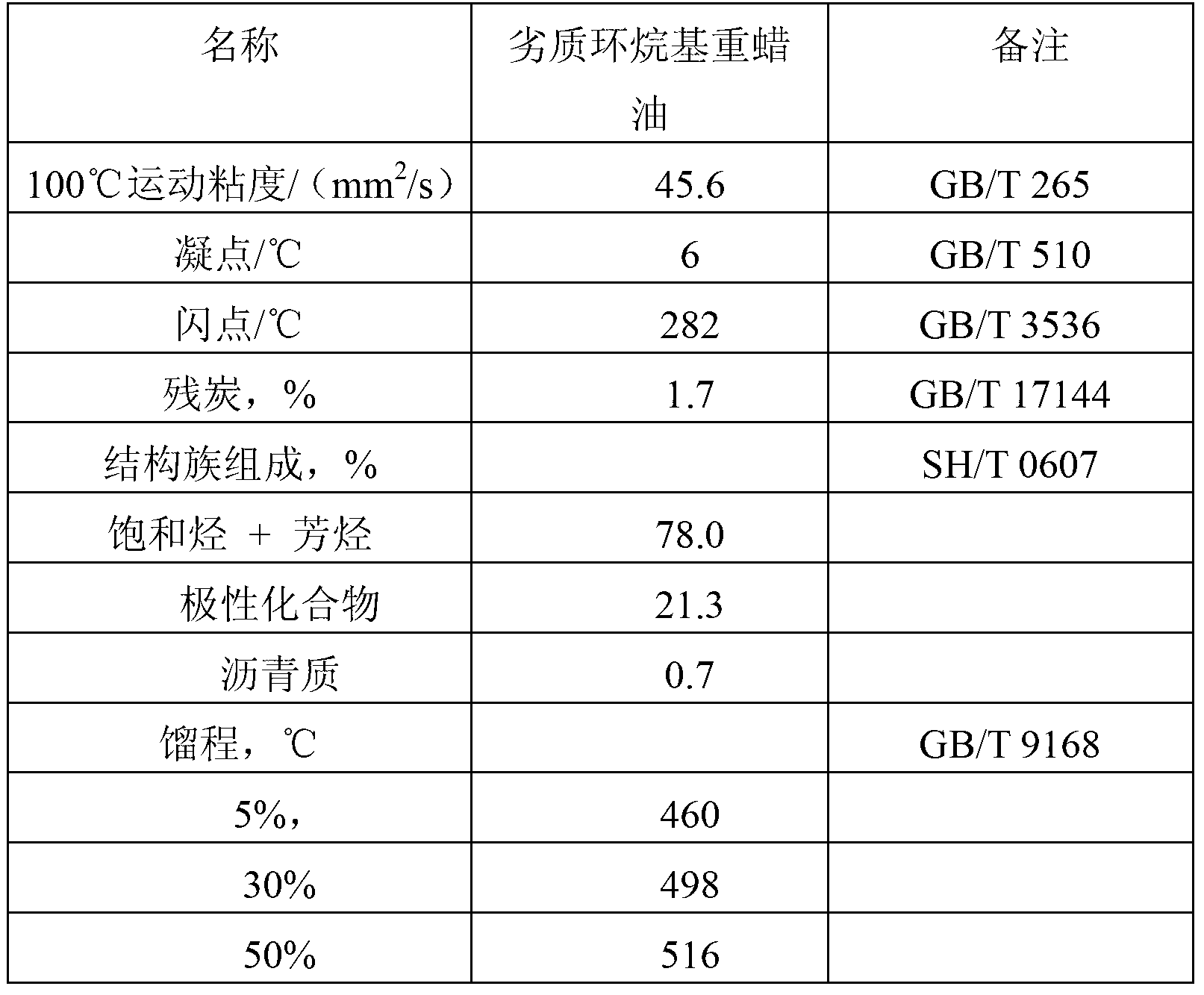

[0033] The low-quality naphthenic heavy wax oil was purchased from Zhonghai Asphalt (Binzhou) Co., Ltd., and its properties are shown in Table 1. From the data in Table 1, it can be seen that the low-quality naphthenic heavy wax oil has a kinematic viscosity of 45.6mm at 100°C 2 / s, the freezing point is 6°C, and has the characteristics of high kinematic viscosity and low freezing point; it can be seen from the structural group composition data that the total content of saturated hydrocarbons and aromatics is 78.0%, and the content of asphaltenes is very high, 0.7%.

[0034] The inferior naphthenic heavy wax oil listed in Table 1 was used as the feedstock oil, and the propane deasphalting pilot plant (manufactured by Luoyang Kaimeisheng Petrochemical Equipment Co., Ltd., the feedstock oil feed rate was 1kg / h, and the product model was KSDA-1000 )experimenting. After the raw material oil is heated, it en...

Embodiment 2

[0042] Embodiment 2, the preparation of environment-friendly rubber oil

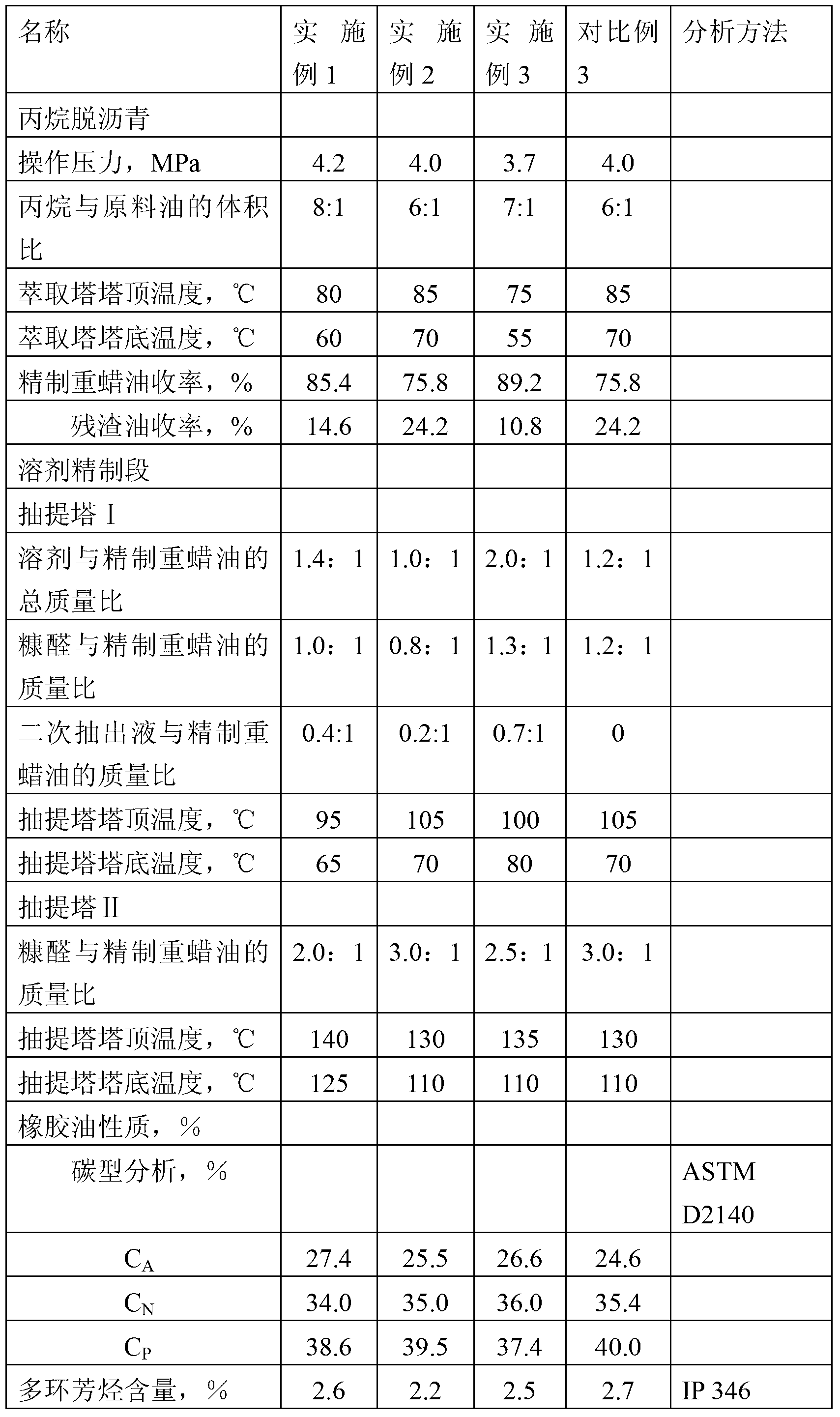

[0043] The raw material oil, test device and preparation method used in Example 2 are exactly the same as those in Example 1, except that the operating conditions are different from those in Example 1. The detailed operating conditions and test results are shown in Table 2.

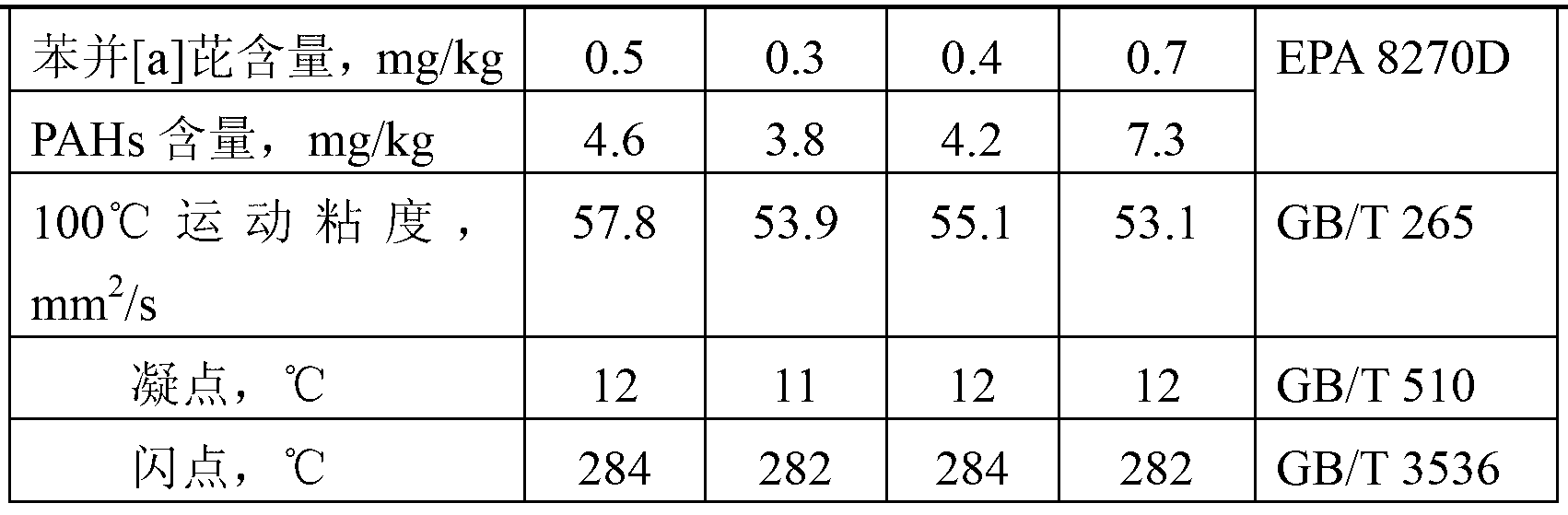

[0044] It can be seen from the data in Table 2 that the C of environmentally friendly rubber oil A The value is 25.5%, C N The value is 35.0%, C P The value is 39.5%, the content of polycyclic aromatic hydrocarbons is 2.2%, the content of PAHs is 3.8mg / kg, and the content of benzo[a]pyrene is 0.3mg / kg.

Embodiment 3

[0051] Embodiment 3, the preparation of environment-friendly rubber oil

[0052] The raw material oil, test device and preparation method used in Example 3 are exactly the same as those in Example 1, except that the operating conditions are different from those in Example 1. The detailed operating conditions and test results are shown in Table 2.

[0053] It can be seen from the data in Table 2 that the C of environmentally friendly rubber oil A The value is 26.6%, C N The value is 36.0%, C P The value is 37.4%, the content of polycyclic aromatic hydrocarbons is 2.5%, the content of PAHs is 4.2mg / kg, and the content of benzo[a]pyrene is 0.4mg / kg.

[0054] Table 1 Raw Oil Properties

[0055]

[0056] Operating conditions and rubber oil properties of table 2 embodiment and comparative examples

[0057]

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com