Method for recycling base oil of waste liquid of oil-based drilling liquid

An oil-based drilling fluid and recovery method technology, which is applied in the field of solid-liquid separation and the recovery of oil-based drilling fluid waste liquid base oil, can solve the problems of low base oil recovery rate, high equipment requirements, and high processing costs, and achieves no The effects of pollution and resource utilization, less equipment investment, and low treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

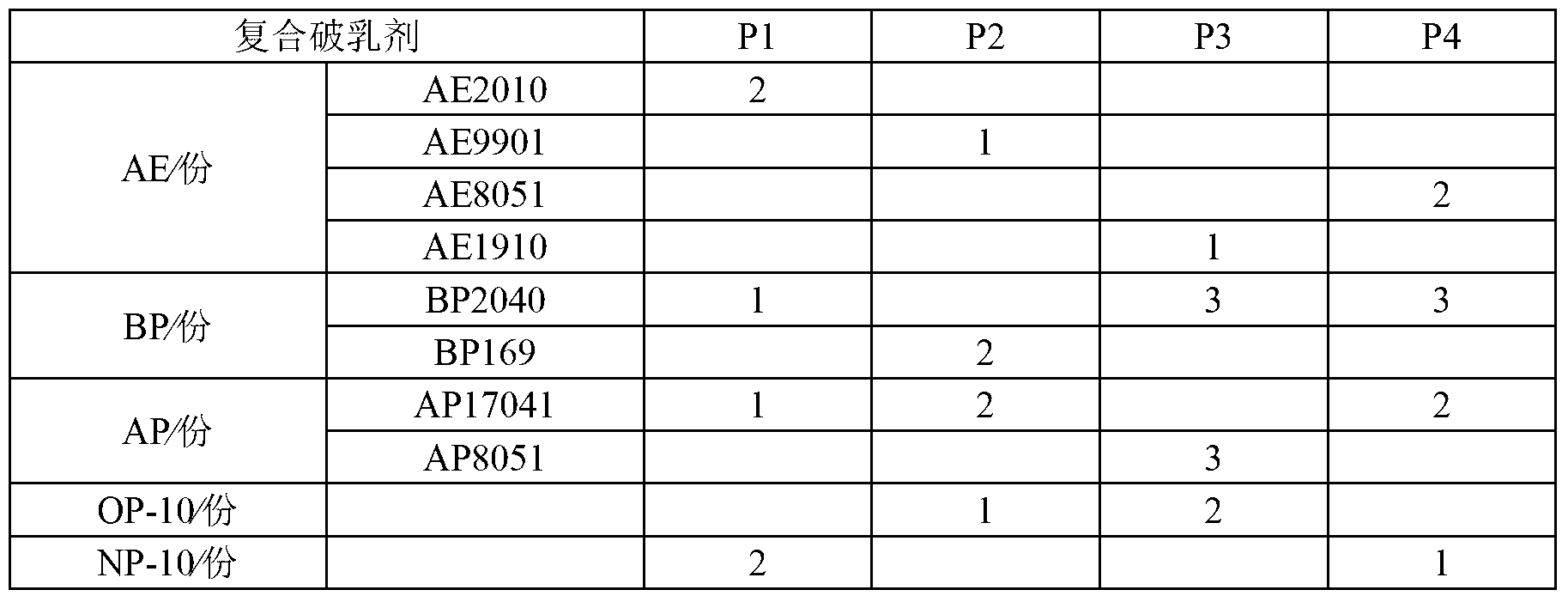

[0028] Put the oil-based drilling fluid waste liquid from an oil field in a container with a stirring device, and in the stirring state, add water-in-oil cationic polyacrylamide emulsion with a mass percentage of 0.2% of the oil-based drilling fluid waste liquid, 0.65 % compound demulsifier P2, 1% sodium dioctyl sulfosuccinate and 0.4% ditetradecyl octadecyl dimethyl ethyl ammonium chloride. During the whole process, every time a drug is added, it must be fully stirred until it is evenly mixed. The resulting mixed solution was separated into solid and liquid with a centrifuge, and the results after separation are shown in Table 3.

[0029] Because the oil-based drilling fluid waste fluid in this example has high viscosity and poor fluidity, the required water-in-oil type cationic polyacrylamide emulsion must be dispersed in diesel oil first, and the water-in-oil type cationic polyacrylamide emulsion and diesel oil The mass ratio is 1:20; the required compound demulsifier P2 a...

Embodiment 2

[0031] Drilling fluid waste from an oil field was placed in a container with a stirring device, and in a stirring state, compound demulsifier P4 with a mass percentage of 0.4% oil-based drilling fluid waste liquid and 0.8% dipentyl sulfo Sodium succinate solution, 0.2% tetradecyl cetyl dimethyl ethyl ammonium dichloride and 0.1% water-in-oil anionic polyacrylamide emulsion. Every time a drug is added, it must be stirred thoroughly. Then the above-mentioned mixed solution was separated into solid and liquid with a centrifuge, and the results after separation are shown in Table 3.

[0032] In this example, the required composite demulsifier P4 and sodium dipentyl sulfosuccinate must be diluted with methanol to form a solution with a concentration of 20% by mass, and then added to the oil-based drilling well according to the above steps. in liquid waste.

Embodiment 3

[0034] The oil-based drilling fluid waste liquid of an oil field is placed in a container with a stirring device, and in a stirring state, water-in-oil type zwitterionic polyacrylamide emulsion with a mass percentage of 0.4% of the oil-based drilling fluid waste liquid, 0.8% compound demulsifier P4, 1% sodium dioctyl sulfosuccinate and 0.3% ditetradecyl octadecyl dimethyl ethyl ammonium dichloride. During the process, every time a drug is added, it must be fully stirred. The above mixed solution was subjected to solid-liquid separation, and the results after separation are shown in Table 3.

[0035] Before treatment, the required compound demulsifier P4 and diisooctyl sodium sulfosuccinate should be diluted with ethanol respectively to a solution with a concentration of 15% by mass, and then added to the waste oil-based drilling fluid in sequence according to the above steps. in the liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com