High-performance easy-construction two-component aqueous epoxy zinc-rich coating and preparation method thereof

A water-based epoxy zinc-rich, two-component technology, used in epoxy resin coatings, anti-corrosion coatings, coatings, etc. The effect of improving the surface state of the coating, low cost and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

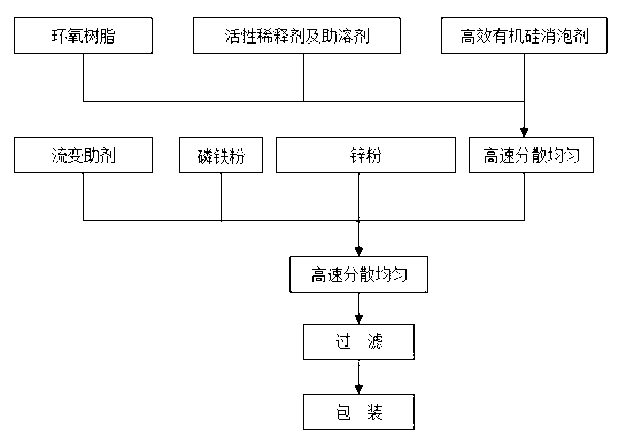

[0030] Below in conjunction with accompanying drawing, invention is further described, and the present invention is not limited to following embodiment:

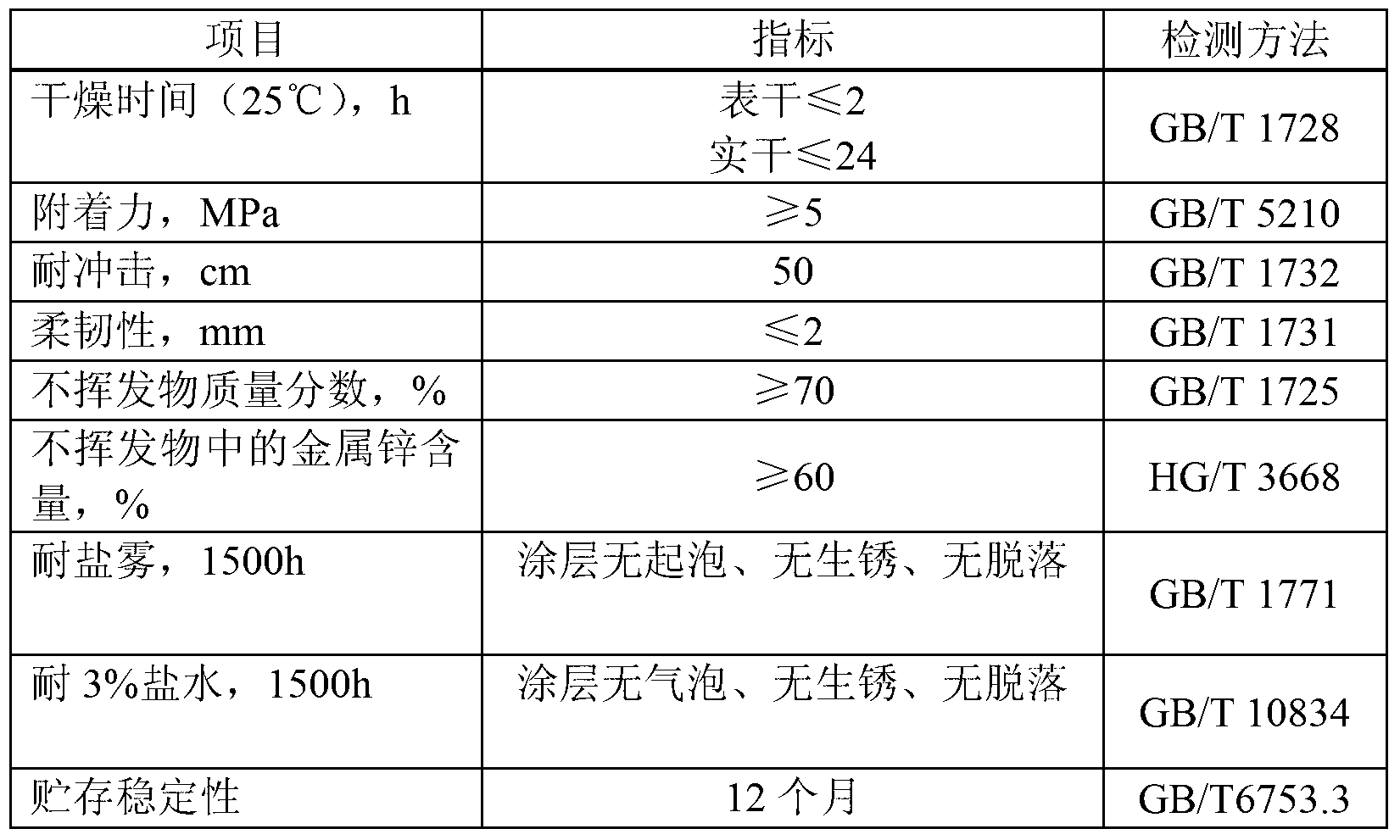

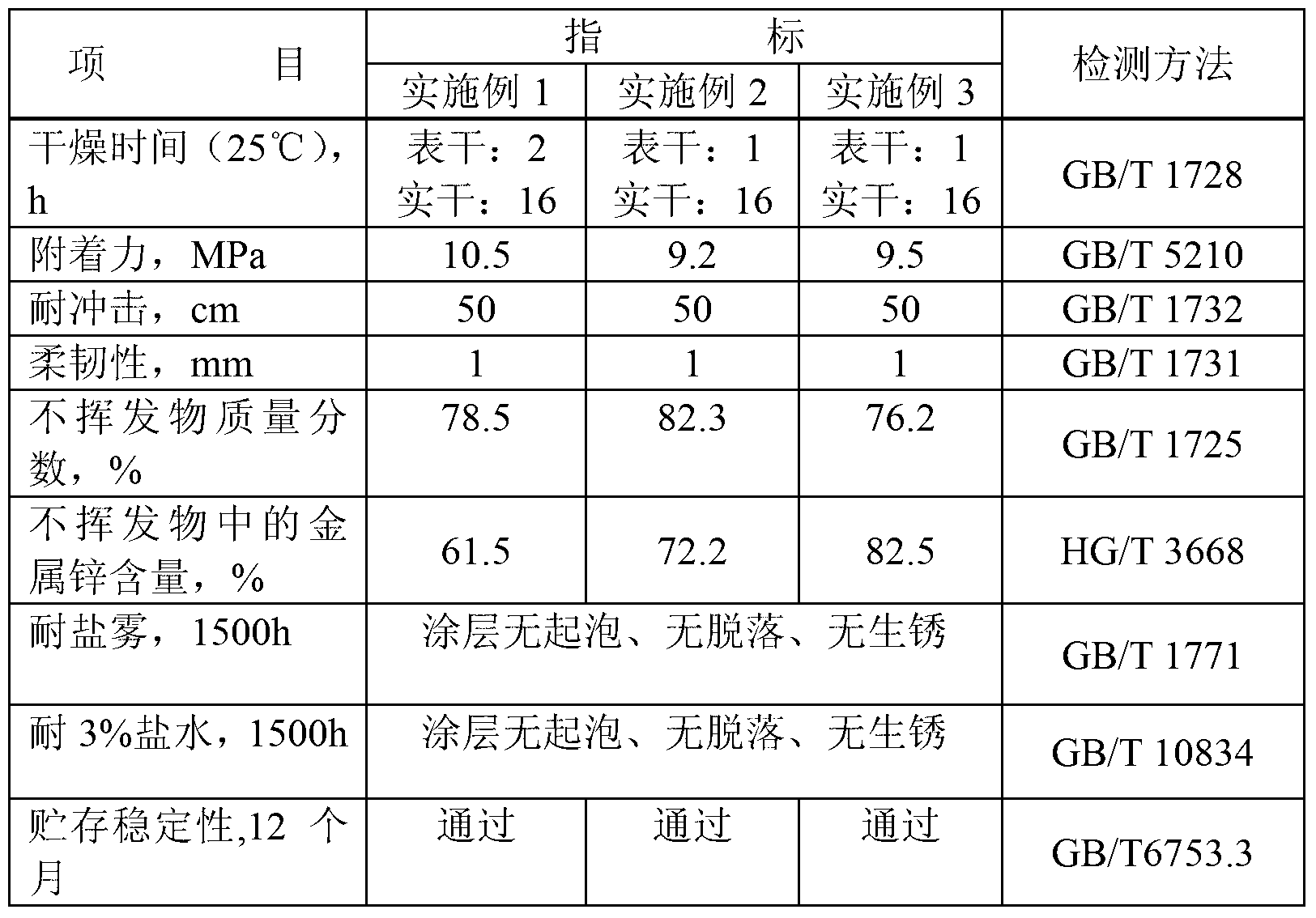

[0031] The embodiment of the high-performance and easy-to-construct two-component water-based epoxy zinc-rich coating of the present invention is shown in Table 1:

[0032] Table 1, embodiment

[0033] Component A raw material name

Example 1

Example 2

Example 3

E51 epoxy resin

15

10

6.5

660A reactive diluent

5

3

2

[0034] BYK-035

0.05

0.5

1

Propylene Glycol Methyl Ether

5

8

10

Ferrophosphorus powder

20

10

5

800 mesh zinc powder

65

75

80

PalyGelXQ-100A Attapulgite

0.5

1.0

1.5

B component raw material name

Example 1

Example 2

Example 3

Air Chemical 721 Curing Agent

20

15

10

Propylene Glycol Methyl Ether

5

3

2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com