Conductive barrier polyethylene composition, its preparation method and application

A composition and polyethylene technology, applied in the field of conductive and barrier polyethylene compositions, can solve the problems of limited application range of materials, high cost of the composition, narrow material processing window, etc., achieve excellent static electricity prevention, and increase the processing window. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

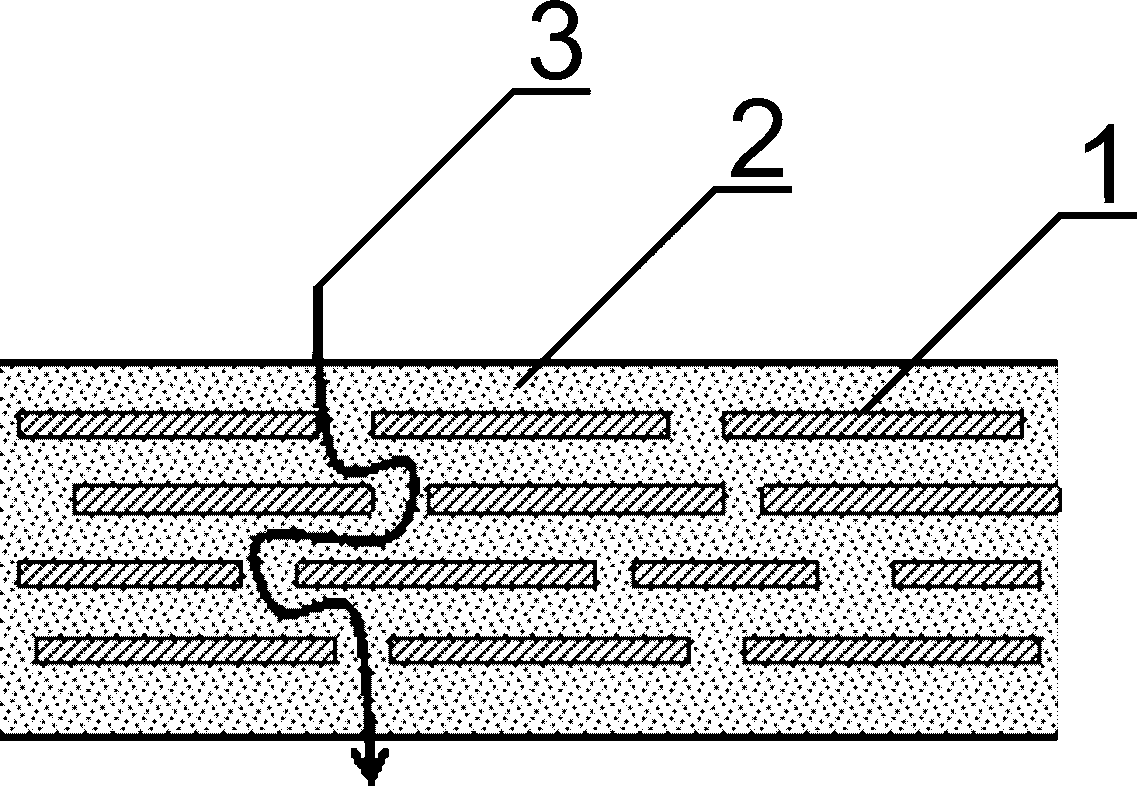

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through specific embodiments. The following examples are preferred implementation forms of the present invention, but the implementation manners of the present invention are not limited by the following examples.

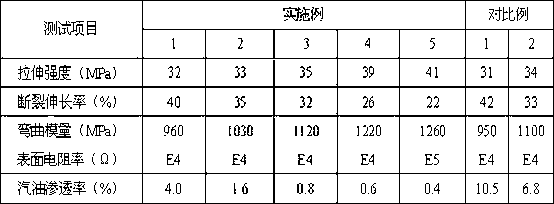

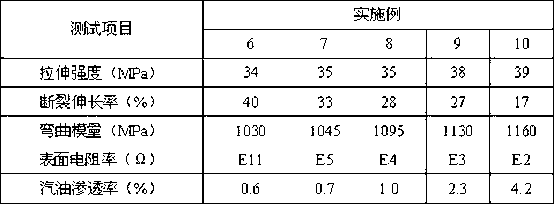

[0035] In the composition formula of the example shown in Table 1: the selected polyethylene is HDPE MS201B of Tatol Company; due to the different melting points and viscosities of polyamides of different types and brands, the melting points selected in this example are 180°C and 220°C respectively , 240°C, 290°C, polyamides with viscosities of 2.1 dL / g, 2.4 dL / g, 3.4 dL / g, 3.8 dL / g, and 4.2 dL / g respectively; the compatibilizer is maleic anhydride grafted polyethylene, The mass part of grafted maleic anhydride is 0.25 parts, and the grade is Dow’s GR320; the grade of carbon black is Ketjenblack EC300JD, the grade of carbon black I is Ketjenblack EC600JD, and the grade of carbon black II is CONDUCTEX 7067; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com