Double-focusing device of light splitting mechanism of laser drilling machine

A laser drilling machine and dual focusing technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of inconsistent multi-head punching effect, etc. The effect of reducing focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

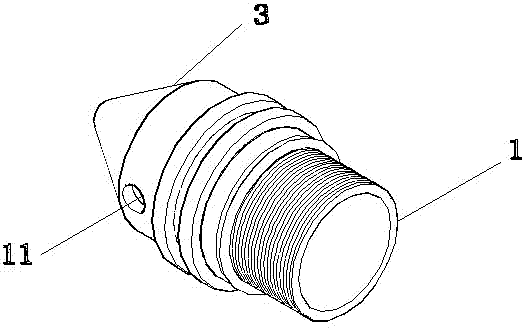

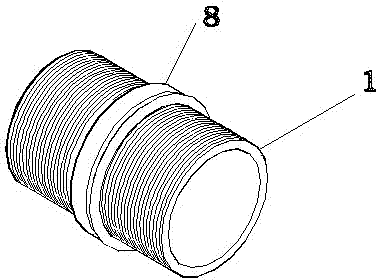

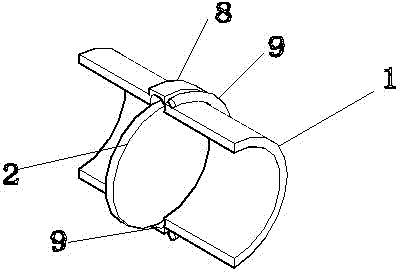

[0031] like figure 1 , 2, 3, 4, and 5, the double focusing device of the beam splitting mechanism of the laser punching machine described in the present embodiment is connected with the laser, the polygon mirror beam splitting system, the punching head and the paper feeding mechanism that drives the continuous motion of the tipping paper, The device includes a primary lens barrel 1, a first focusing lens 2, a secondary lens barrel 3, a second focusing lens 4, a controller 5, an air pressure sensor 6, and an air supply pipe 7; A cylindrical part with external threads of different diameters is provided, an annular boss 8 is provided on the outside of the junction of the front and rear two external threads, and a groove 9 for installing the first focusing lens 2 is provided on the corresponding inner side; the secondary lens barrel 3 The lower part is a hollow cone with openings, the upper part is cylindrical, and the upper part is provided with an internal thread that cooperate...

Embodiment 2

[0033] like figure 1 , 2 , 3, 4, 5, 6, and 7, the double-focusing device of the beam splitting mechanism of the laser punching machine described in this embodiment is connected with the laser, the polygon mirror beam splitting system, the punching head and the continuous movement of the driving tipping paper. The paper mechanism is connected, and the device includes a primary lens barrel 1, a first focusing lens 2, a secondary lens barrel 3, a second focusing lens 4, a controller 5, an air pressure sensor 6, and an air supply pipe 7; the primary lens barrel 1 The two ends are respectively provided with cylindrical parts with different diameters of external threads, and an annular boss 8 is provided on the outside of the junction of the front and rear two external threads, and a groove 9 for installing the first focusing lens 2 is provided on the corresponding inside; the two The lower part of the primary lens barrel 3 is a hollow cone with holes, the upper part is cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com