A secondary self-propagating welding method for a cathode soft strip and a large busbar for an aluminum electrolytic cell

A technology of self-propagating welding and cathode soft tape, which is applied in the direction of aluminothermic welding equipment, welding equipment, welding medium, etc., can solve problems such as inability to weld, increase energy consumption, and soft tape melt-through, and achieve good conductivity and workpiece strength The effect of high and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

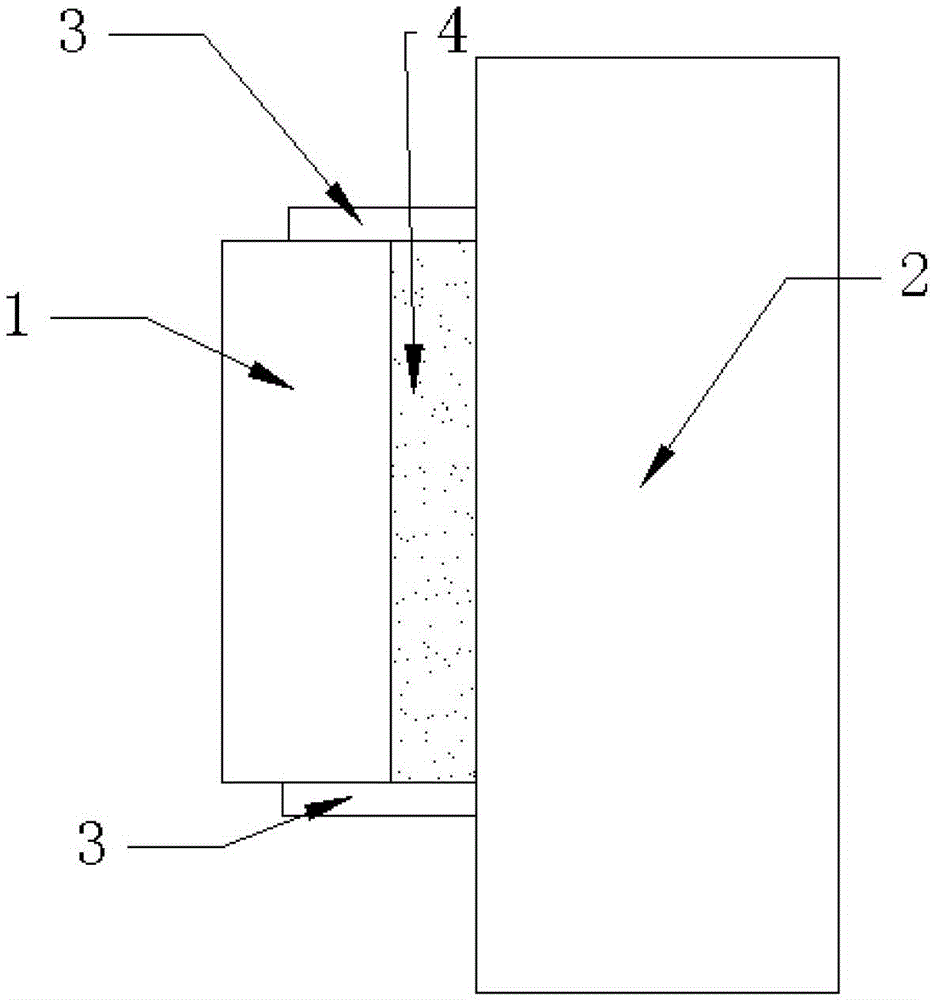

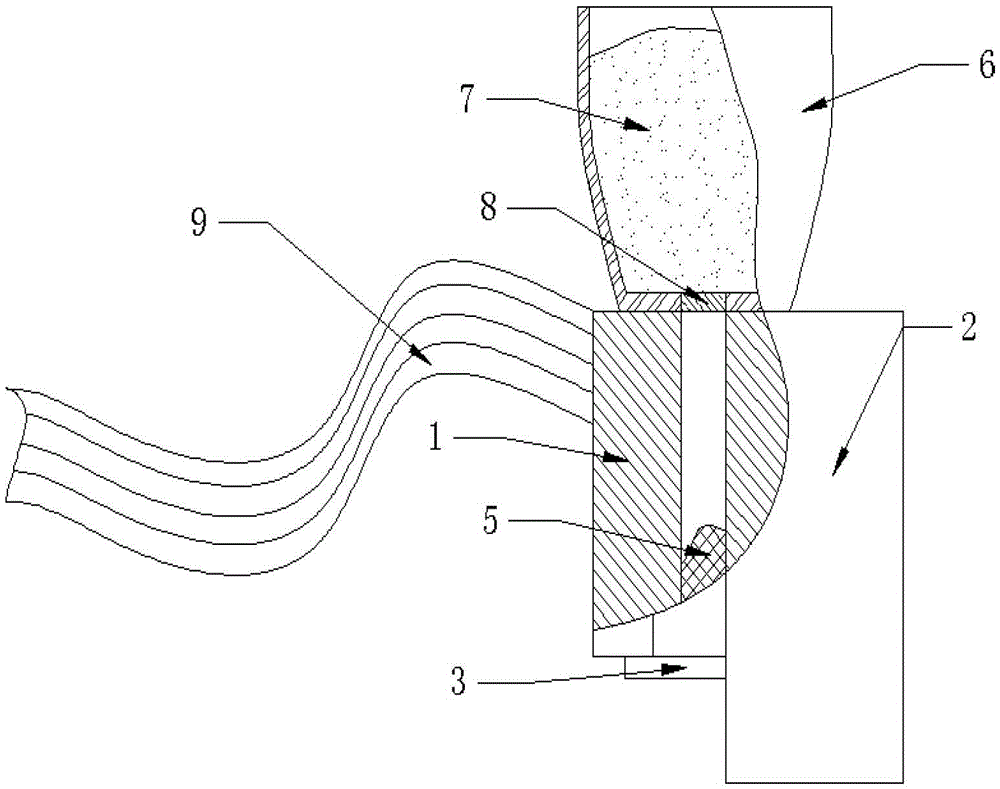

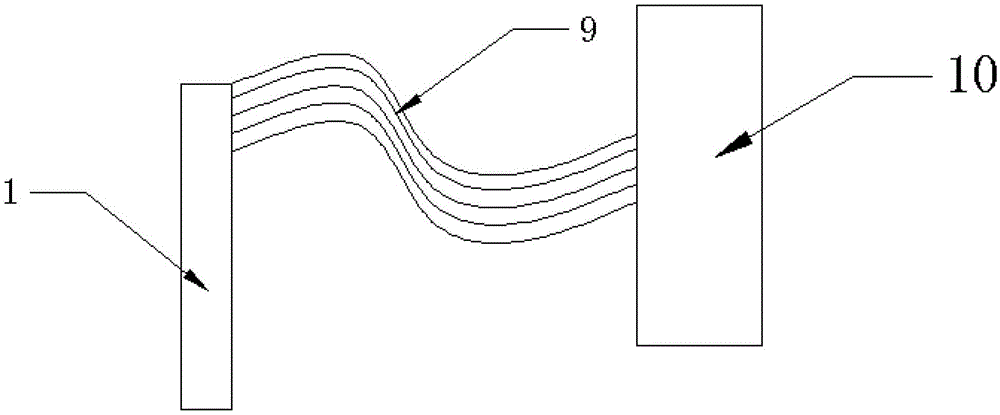

[0021] Embodiment one: if figure 1 , 2 , 3, and 4 show:

[0022] A secondary self-propagating welding method for cathode flexible strips and large busbars used in aluminum electrolytic cells, welding of small soft strips for cathodes of 3106# electrolytic cells of Ningdong Branch of Qingtongxia Aluminum Co., Ltd. First, use gas cutting or other mechanical methods to remove the used cathode soft belt from the cathode steel rod and the busbar. Utilize electric arc welding to weld aluminum plate 1 to one end of new soft belt 9 in the overhaul workshop, and weld steel-aluminum explosive block 10 on the other end. The thickness of the aluminum plate 1 is 35mm, and the length and width are 190mm and 220mm respectively. First, use a grinder to polish the welding surface of the busbar 2 and the aluminum plate 1 to remove scale and oil, and apply aluminum flux on the welding surface of the aluminum plate and the busbar. Clamp the graphite plate 3 on the bottom and left and right si...

Embodiment 2

[0024] Embodiment two: if figure 1 , 2 , 3, and 4 show a secondary self-propagating welding method for aluminum electrolytic cells with cathode soft strips and large busbars, welding of small soft strips for cathodes of Qingtongxia Aluminum Co., Ltd. Ningdong Branch 3110#. First, use gas cutting or other mechanical methods to remove the used cathode soft belt from the cathode steel rod and the busbar. Utilize electric arc welding to weld aluminum plate 1 to one end of new soft belt 9 in the overhaul workshop, and weld steel-aluminum explosive block 10 on the other end. The thickness of the aluminum plate 1 is 35 mm, and the length and width are 150 mm and 200 mm, respectively. First, use a grinder to polish the welding surface of the busbar 2 and the aluminum plate 1 to remove scale and oil, and apply aluminum flux on the welding surface of the aluminum plate and the busbar. Clamp the graphite plate 3 on the bottom and the left and right sides of the weld seam with a clamp ...

Embodiment 3

[0026] Embodiment three: as figure 1 , 2, Shown in 3 and 4, a secondary self-propagating welding method for aluminum electrolytic cells with cathode soft strips and large busbars, welding of small soft strips for cathodes of Qingtongxia Aluminum Co., Ltd. Ningdong Branch 4213#. First, use gas cutting or other mechanical methods to remove the used cathode soft belt from the cathode steel rod and the busbar. Utilize electric arc welding to weld aluminum plate 1 to one end of new soft belt 9 in the overhaul workshop, and weld steel-aluminum explosive block 10 on the other end. The thickness of the aluminum plate 1 is distributed in a gradient, with the top 20mm and bottom 30mm, and the length and width are 190mm and 220mm respectively. First, use a grinder to polish the welding surface of the busbar 2 and the aluminum plate 1 to remove scale and oil, and apply aluminum flux on the welding surface of the aluminum plate and the busbar. The graphite plate 3 is clamped on the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com